Description

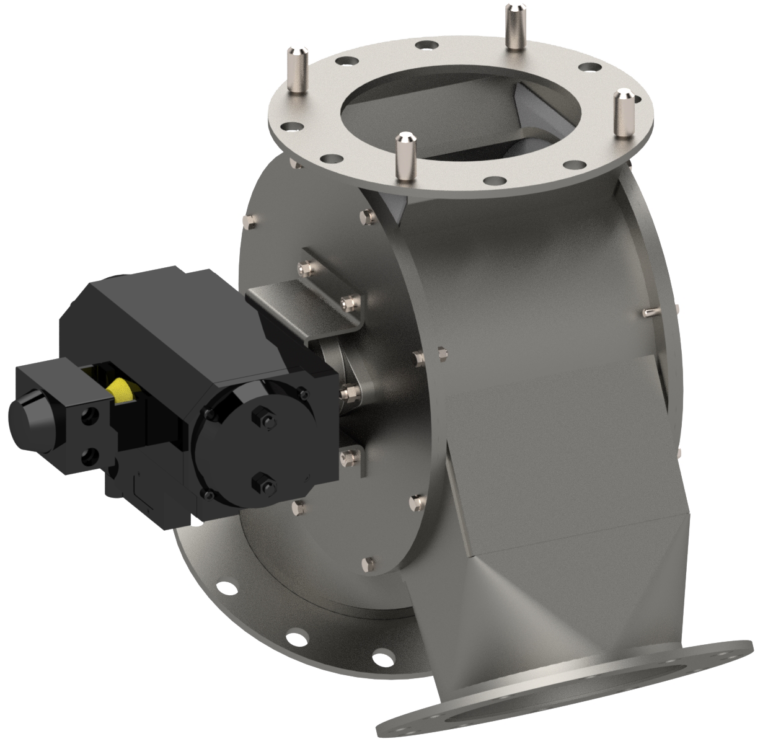

The Young Industries, Inc. Rotary Vane Diverter Valves, are used in a wide variety of gravity flow bulk material applications were a minimum dusting between the legs is acceptable. The Rotary Vane Diverter Valves are designed with the diversion legs offset either 30° or 45° from the inlet leg.

Flange Mounted Bearing provide a smooth operation.

“O” ring seals on each end of the vane shaft prevent dust leakage to the exterior. The flange mounted bearing provide smooth and rugged operation.

The Rotary Vane Diverter Valve is offered either as 30°diversion leg offset or 45° diversion leg offset. The change of direction is accomplished by changing the position of the blade from one line to the other by a rotary actuator.

The Rotary Vane Diverter Valve has heavy construction along, and the valve’s actuator is direct coupled to the bucket shaft . This arrangement distributes torque directly to the vane shaft, eliminating stress to the valve components. This keeps production loss, downtime and maintenance cost to a minimum.

As a result, the Young Industries, Rotary Vane Diverter Valves have been proven to provide superior performance and reliability in a wide range of bulk materials handling applications, and offer a low cost of ownership.

Specifications

- The Rotary Vane Diverter Valves are designed for mounting on a gravity discharge line to divert each leg 30° or 45° from the straight inlet leg and were cross over dusting is minimized.

- The Young Industries, Inc. Rotary Vane Diverter Valves, are used in a wide variety of gravity flow bulk material applications were material needs to be diverted 30° or 45° from the inlet leg and were a minimum dusting between the legs is acceptable. The diverter vane is constructed with flexible urethane seal.

- The Rotary Vane Diverter Valve is designed for a 2 PSIG internal or external pressure. It is available in standard sizes from 4″ through 16″ square flange sizes. Round flange are available.

- Two Models of the Rotary Vane Diverter Valve are offered. One model has 30° diversion leg offset, and the other has a 45° diversion leg. The change of direction is accomplished by changing the position of the vane from one line to the other by a rotary actuator.

- The Rotary Vane Diverter Valve has heavy construction along, and the valve’s actuator is direct coupled to the vane shaft . This arrangement distributes torque directly to the vane shaft, eliminating stress to the valve components. This keeps production loss, downtime and maintenance cost to a minimum.

- Flange Mounted Bearing provide a smooth operation.

- “O” ring seals on each end of the blade shaft prevent dust leakage to the exterior. The flange mounted bearing provide smooth and rugged operation.

- The Young industries Rotary Vane Diverter Valves are available with a variety of features to handle a wide range of process requirements.

- 2 PSIG Housing and differential pressure or vacuum

- Fabricated designs

- Materials of construction: fabricated carbon steel, fabricated stainless steel or fabricated aluminum

- Raw materials are traceable to standard specifications with ASTM the most used specification.

- Square inlet flange

- Square discharge flange

- Up to 250°F operation temperature, with designs offered to withstand up to 1600°F temperature

- Flange mounted precision ball bearings

- “O” ring shaft seals

- Heavy shafts secured to eliminate shifting in the housing

- Grounding and bonding connection to NFPA specifications

- Painted blue enamel or Steelcote stainless steel paint

- Completely assembled and tested.

- Rotary pneumatic operator, with NEMA 4 single solenoid valves, single-pole double-throw and two (2) limit switches – one indicating for each leg.

- Electric operator, with two (2) limit switches – one switch for each leg.

- Manual operator

- High pressure design available

- High temperature design available

- Round inlet and outlets with 150 lbs drilling flanges

- Inspection door

- Blade removal without removing from line.

- Special sizes available

- Special materials of construction including: 316 Stainless steel, Hastelloy, Titanium

- Interior coating to provide abrasive resistance to material release including: chrome plating, nickel plating, tungsten carbide, Stellite, Teflon

- Interior polishes and cleanup

- Special seal materials as graphite, food grade TPFE

- Special bucket designs available

- Flexible tips of Teflon or polyurethane

- Painted or coated per customers specification