Description

High capacity…low velocity conveying

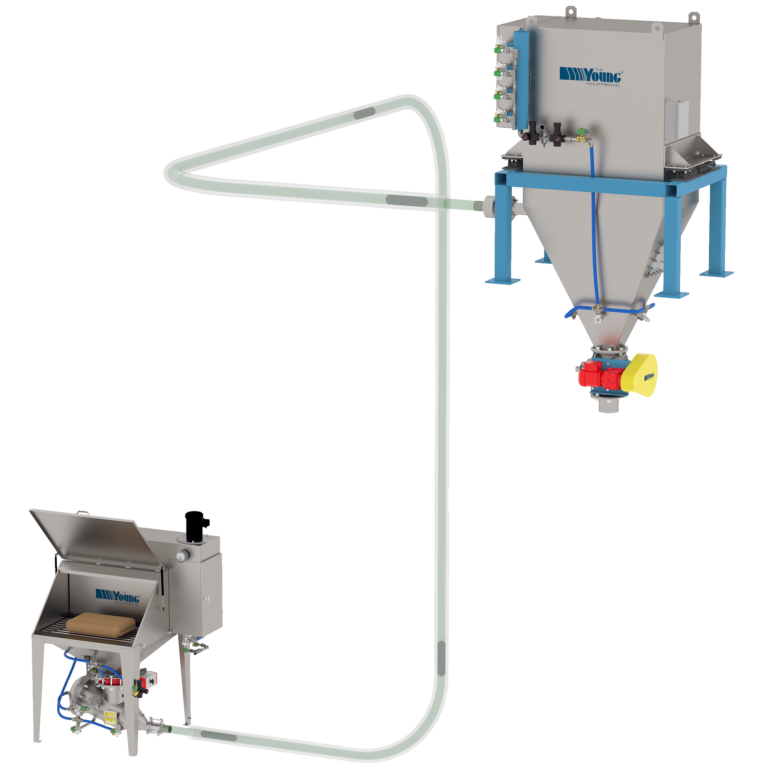

The Young Industries Multi-Phase Product Pump is a compact, self-contained, easily installed system for the conveying of powders and granular materials. It’s a low cost solution for transferring raw material and additives from bulk containers to bins or process equipment. It is designed for applications where conventional pneumatic systems are economically impractical.

When used with The Young Industries Filter Bag Dump Station, the patented Multi-Phase Product Pump is an efficient, self-contained, dust-free system, with transfer capacities from 50 to 400 cu. ft. per hour. The unit uses plant compressed air or nitrogen to operate, conveying product over distances up to 600 feet.

Reliability

The Young Industries Multi-Phase Product Pump delivers your material at the required conveying rate and without downtime. The units handle a wide variety of bulk materials, including free flowing powders, pellets, granular materials and pigments. The Product Pump is custom designed to match the basic handling characteristics of your materials and conveying requirements. The unit then can be optimized using the adjustable conveying cycle timers. These PLC timers can be tuned to the best results under the operation conditions. The unit can run unattended while the operator completes other tasks.

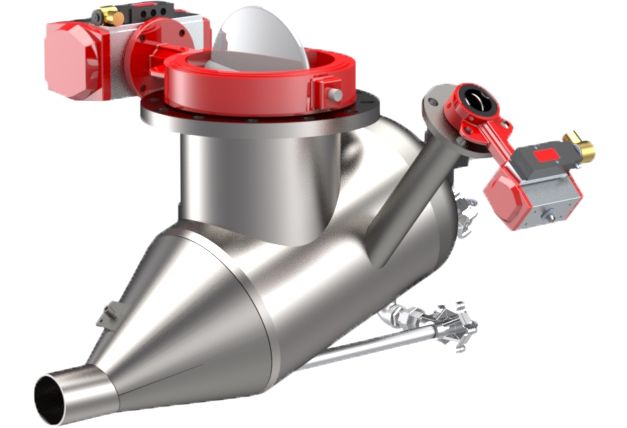

The air volume and pressure is controlled by The Young Industries, Inc. patented M/P Valve to efficiently and gently transfer your material to the next processing point without plugging or excessive velocity.

Installation is easy because the unit is self-contained, pre-wired, pre-piped and tested before it is shipped. In many applications, the Multi-phase Product Pump is factory assembled to a bag dump, inlet hopper or bulk bag unloading equipment.

Efficiency

The Multi-Phase Product Pump operation cycle starts when the inlet valve opens to allow the product to gravity flow in to the transport vessel. The inlet valve closes and the compressed gas starts conveying the product through the convey line. For applications where the conveying distance is long, an inline check valve is located in the convey line to seal the downstream pressure which also minimizes venting. The transport vessel is then vented. The cycle is repeated and the product is transferred at a uniformly controlled rate.

When the conveying gas or air is controlled to a minimum velocity, you reduce generation of fines and degradation of the conveyed products. The gas controls also reduces wear on the system components and convey line when handling abrasive materials.

Adaptable to Your Application

The compact design of the Multi-Phase Product Pump makes it ideal for mounting under new or existing equipment. The horizontal pump’s low profile allows it to easily fit under bag dump stations and bulk bag unloading frames. The operator can then dump bags at a convenient operating height.

Batch processes requiring a number of products can take advantage of the Product Pump’s ability to handle a wide range of materials. A Product Pump system can be used to fill a weigh hopper from a bulk bag or bag dumping station. The Multi-Phase Product Pump can be installed under a silo or mixer to transfer your material to the next processing operation.

Configurations

Vertical – for total clean-out between operations.

Horizontal – for areas with low headroom.

Inclined – for good clean-out and low headroom.

Commercially Available Components

The Product Pump uses commercially available components, for reduced inventory and easier maintenance. The units are pre-wired and pre-piped, only one electrical connection and one air connection are required.

For over 75 years, The Young Industries, Inc. has interpreted customer’s requirements and then developed easy to operate, cost effective and reliable bulk materials handling systems.