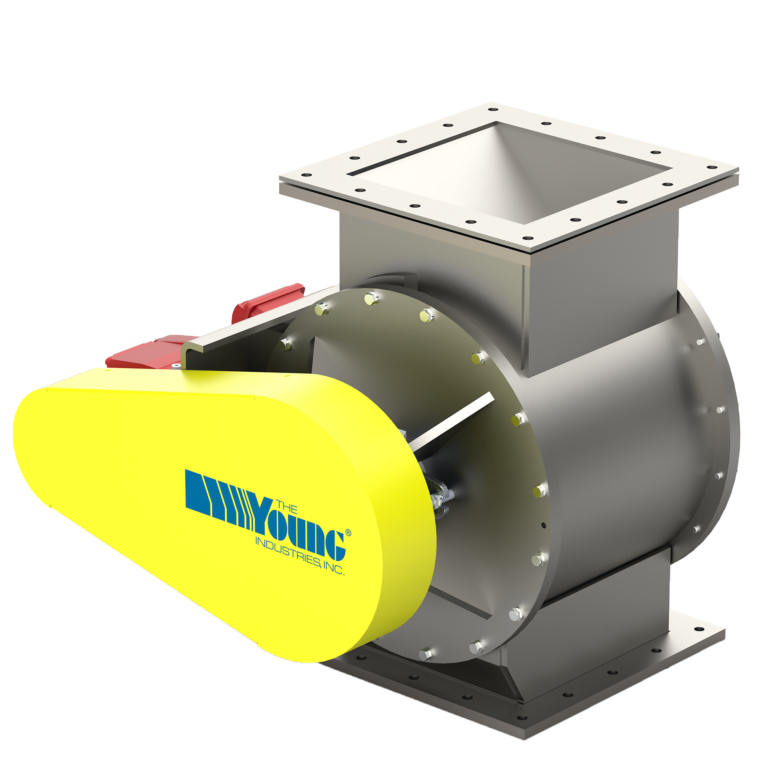

Description

The Young Industries, Inc. Model RNHC Rotary Valve is a straight drop-thru valve specifically designed for metering pelletized or prill materials with particle sizes 1/16” to 1/4”. In many applications, this valve is used for variable speed and rate control. This is a vertical drop through rotary valve with a pellet-flow inlet throat and rotor that minimizes clipping of the pellets as they enter the rotor pockets.

In a conventional drop through rotary valve there is a point where the rotor will clip pellets at the downward side of the inlet throat. The clip point is eliminated with the RNHC Valve. The special inlet throat deflector wipes the pellets into a secondary set of rotor pockets that sweep the pellets instead of shearing them.

Specifications

The Model RNHC Rotary valve uses an eight-vane rotor to ensure that two blades are always positioned between the inlet and discharge. This two-blade seal and precision machined housing ensures that there is minimum air or gas leakage when used to seal in two different pressure or vacuum zones.

Standard valve sizes are 4” through 12” with larger sizes available.

When the application requires metering pellets, Young Industries Model RNHC Rotary Valve will give you the control you need. As with all Young Industries Rotary Valves, we can design and manufacture the valve for high pressure, high temperature, or low leakage rate conditions. Special is our standard.

- Heavy duty construction with 15 PSIG

- internal and differential pressure rating.

- Fabricated construction of carbon steel, or 300 series stainless steel.

- Standard design/operating temperature up to 250°F.

- Round or square inlet and discharge flanges.

- Outboard-mounted precision ball bearings.

- Packing gland provides a tight rotor shaft seal with four rings of PTFE impregnated Kevlar.

- Open or shrouded rotors.

- End plates are piloted to assure concentricity of the housing so that tight internal clearances between rotor and housing is provided.

- High internal pressure designs up to 350 PSIG.

- Roller chain drive with parallel shaft TEFC driven gearmotor is standard with explosion proof motors of any specified manufacturer available.

- Shaft mounted drive is available.

- Special materials of construction including various grades of Stainless Steel, Hastelloy, or Titanium

- Interior polish or electro-polish per application requirement.

- Special packing materials of graphite, food grade PTFE or as needed by process.

- Interior coating for providing abrasion resistance or material release include hard chrome plating, nickel plating, tungsten carbide, Stellite, or Teflon.

- Lantern ring with purge connection in the packing gland.

- Rotor shaft Mechanical Seals.

- Self-adjusting packing follower.

- Shaft seal coatings.

- Direct venting, with vent installed in the housing.

- End plate purges.

- Side access/inspection panel for access to the rotor interior.

- Rotor tips and edges can be beveled.

- Replaceable rotor tips of flexible or abrasion resistant materials.

- Exterior painting and coatings to meet customer specifications.