Bulk bags of various powders are loaded into an existing process vessel. The bulk bags were lifted by hoist and the operator reaches under the bag to untie the discharge spout. The powder flows freely from the bulk bag into the hopper below.

The concern with this operation is operator safety. A system is needed to eliminate the operator from reaching under a suspended bulk bag. An added concern is that the environment around the tank is corrosive and carbon steel will rust quickly

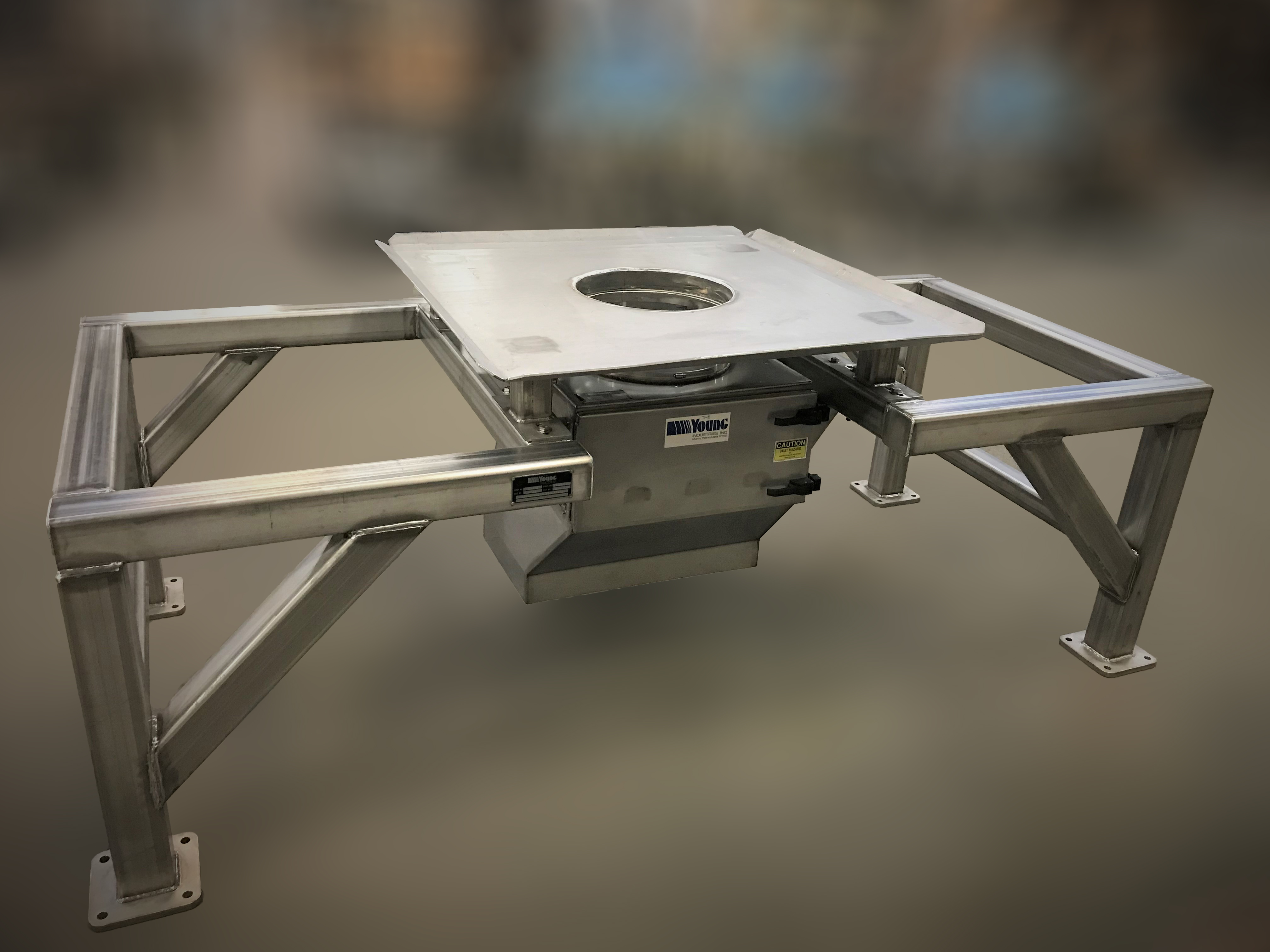

304S/S Frame with flat pan and Access Hopper

Solution

Young Industries Engineers met with the customer and established the available space to unload the bulk bags. A special support frame is needed to straddle the mix tank for powder to feed directly to the rectangular opening of the tank.

Product Line Report – Bulk Bag Unloading Systems