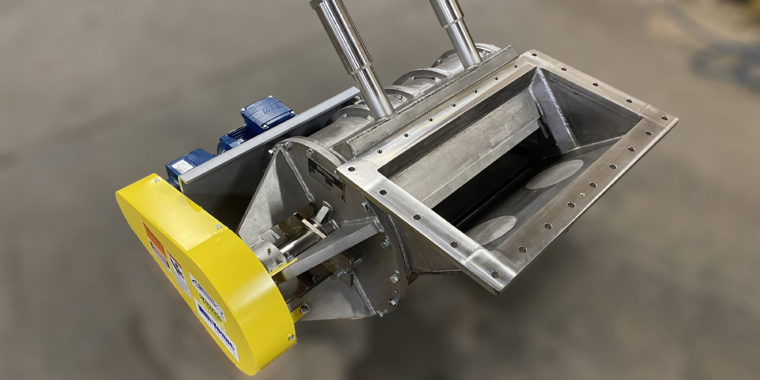

The customers application included metering free flowing Spherical beads in a process at a variable rate. Due to the size and shape of the process vessel above the rotary valve, a large rectangular flange connection is needed. The beads are 1/8” diameter and weigh 125 lbs. per cu. ft. The operating temperature is 1000° F.

Refurbishing a Rotary Valve

Rotary Valves are often the most critical part of a powder handing system. These Valves are often in service for many years with little maintenance or upgrades. Young Industries has always offered refurbishing and rebuild services to our complete line of rotary valves.

Refurbishing Rotary Valves

Receiving the Rotary Valve

In 1990, Young Industries made several 20” Model LH Rotary Valves for handling abrasive corn-based powder. These valves were manufactured with heavy wall housings with interior bore hard surfaced with Stellite. In 2017 our Engineers were contacted by the user to discuss a change in the application for one of the 20” rotary valves. For this application the rotary valve would be required to comply with NFPA 69 standards. After the initial discussions with the user it was decided that one of the 20” Model LH Rotary Valves would be returned to Young Industries for an evaluation to determine if it could be refurbished and used for the application.

Young Industries Rotary Valve Calculator

A Young Industries Rotary Valve Calculator Has Finally Been Created.

Young Industries Rotary Valve Calculator has finally been created, and it has a wide range of helpful features. Our app is a simple and easy way to be able to calculate what RPM the valve will be working at based on capacity per hour, and the bulk density.