Description

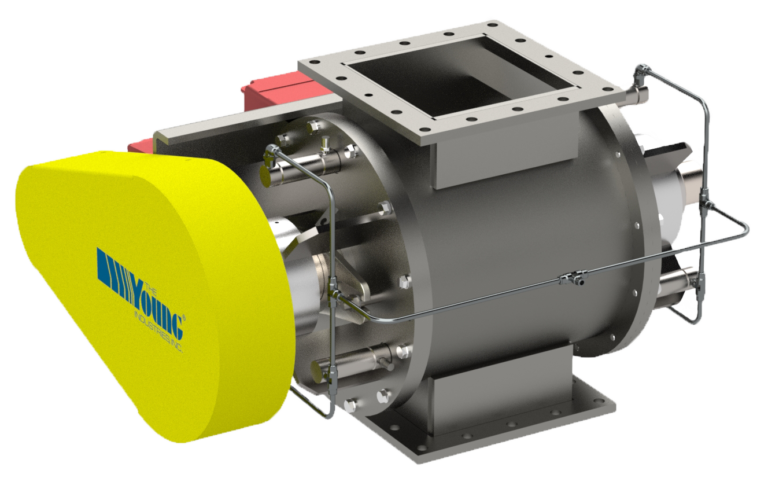

The Young Industries, Inc. Model “ES” (End Seal) Rotary Valve is a Drop-Thru-Airlock Feeder Valve, either a “HC” (High Capacity) or “LH” (Low Headroom) or “SE” (Side Entry) model designed to reduce differential pressure leakage. Applications utilizing this valve see leakage reduced by approximately 50%.

The Model “ES” Rotary Valve works by using peripheral rings to seal against the rotor shroud and eliminate axial leakage. These peripheral rings are continuously adjusted with pneumatic cylinders to provide the proper force needed to reduce leakage.

Specifications

The Young Industries, Inc. Model “ES” (End Seal) Rotary Valve reduces air or gas leakage through the valve by approximately 50%. The Model “ES” basically eliminates the air leakage which occurs between the rotor edges and the end plates. Peripheral rings seal against the rotor shroud.

The Model “ES” Valve is a Drop-Thru-Airlock Feeder Valve, furnished as either a “HC” (High Capacity) or “LH” (Low Headroom) or “SE” (Side Entry) model with peripheral sealing rings that press against the rotor shroud to reduce leakage through the valve.

The Leakage is reduced by approximately 50%. The peripheral rings are continuously adjusted using pneumatic air cylinders to provide constant force on the ring.

With this design, you will get a more reliable feeding of product especially when handling products having a low bulk density and flow characteristics.

The Model “ES” Rotary Valves are available with different rotor designs and wide variety of features to handle a wide range of process requirements.

- Peripheral sealing rings between the rotor shroud and the end plate.

- 15 PSIG Housing and differential pressure or vacuum

- Minimum four blade sealing with two (2) blade sealing on each side.

- Fabricated or cast designs

- Materials of construction: Cast or fabricated carbon steel, cast or fabricated stainless steel and cast or fabricated Aluminum

- Raw materials are traceable to standard specifications with ASTM the most used specification

- Round or square inlet flange

- Round or square discharge flange

- Up to 250°F operation temperature, with designs offered to withstand up to 1600°F temperature

- Outboard-mounted precision ball bearings

- Packing gland rotor shaft seal consisting square braided Kevlar impregnated with PTFE packing, 4 rings per side and held in place by an aluminum packing follower.

- Eight (8) bladed rotor with twelve (12) bladed rotor for rotary valves over 12″ size to provide low operating air or gas leakage.

- Rotor assembled near-perfect concentrically to the housing

- Heavy rotor shafts secured to eliminate shifting in the housing

- Only furnished with shroud rotors available with four (4) different types of rotors. The types are “A”- Standard, “B &C”- partially filled and “D” – adjustable tips

- Grounding and bonding connection to NFPA specifications

- Right-angle gearmotor, side mounted, 3 phase, 60 Hertz, 230-460 volts, TEFC and roller chain drive and safety to OSHA requirements.

- Painted blue enamel or Steelcote stainless steel paint

- Completely assembled and tested.

- High temperature design to 1600°F

- Special Sizes and double length styles available

- Drive and accessories are usually supplied consisting of a right angle gear motor, sprockets, drive chain and safety guard. TEFC or Explosion proof motors, direct connected and other special drive available

- Special materials of construction including: 316 Stainless steel, Hastelloy, Titanium

- Interior coating to provide abrasive resistance to material release including: chrome plating, nickel plating, tungsten carbide, Stellite, Teflon

- Interior polishes and cleanup

- Special packing materials as graphite, food grade TPFE

- Air purge packing glands

- Lip seal packing

- Self adjusting packing follower

- Mechanical rotor shaft seals

- Shaft seal area polishes

- Inlet material deflector

- Venting Thimble

- Housing vent

- End plate purges

- Rotor tips and edges beveled

- Rigid or flexible tips of brass or polyurethane

- Painted or coated per customers specification

Standard Drawings

Videos

Warning

Some machines in this section are shown with guards or covers removed for the purpose of illustration. Machines must not be operated with guards, covers, or other protective devices removed or disabled.