Full-Line Material Handling Expertise

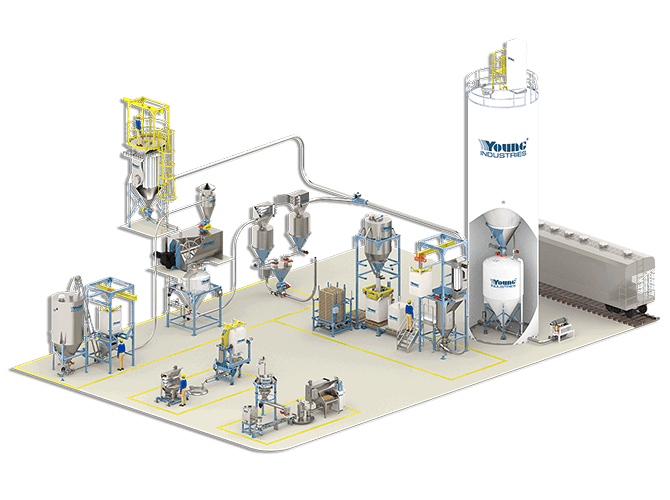

Keep your production lines running smoothly and efficiently. From precision weighing and batching to conveying, mixing, and filtration solutions for the toughest applications, we offer a full range of equipment to handle your bulk material handling needs.

We partner with trusted suppliers, prioritize sustainable practices, and hold ourselves to the highest quality standards. Whether you need a single component or a complete system, Young Industries has the expertise and experience to deliver results.

Industries See All Industries

Precisely meter and handle cohesive battery materials for reliable, high-quality production.

Learn More

Conquer flow challenges and prevent downtime with solutions for even the most stubborn materials.

Learn More

Achieve consistent blends and a smoother flow for a wide range of ceramic materials.

Learn More

Handle sensitive chemicals safely and precisely with custom-engineered solutions.

Learn More

Overcome flow challenges and maintain product integrity with tailored material handling systems.

Learn More

Transform waste into valuable resources with efficient material handling solutions.

Learn More

Ensure clean, efficient water treatment processes with reliable material handling equipment.

Learn More

Ensure food safety and optimize production with reliable and efficient material handling.

Learn MoreMaterial Handling Equipment

Increase your process production with TransFlow® Products. Built tough for challenging applications, it boosts flow rates, cuts maintenance, and lowers costs.

Learn More

Keep your materials moving and your process airtight with our rugged rotary valves. Built to last and engineered for minimal leakage, they'll save you money in the long run.

Learn More

Need to redirect your material flow? Our diverter valves are built tough and designed for minimal downtime, keeping your production line humming.

Learn More

Tired of fighting with finicky feeders? Our Stinger® Screw Feeders handle even the toughest powders with ease. Less downtime, less maintenance, more productivity.

Learn More

Move your materials efficiently and reliably with our rugged conveyors. Built to last and engineered for your specific needs, they'll keep your operation moving.

Learn More

Handle bulk bags with ease using our rugged and reliable loading systems. We've been innovating since 1947, so you can trust our solutions to get the job done right.

Learn More

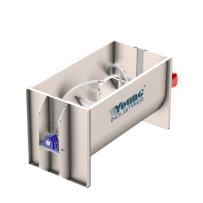

Dump bags safely and efficiently with our filter-bag dump stations and compactors. Minimize dust, maximize productivity, and keep your operation clean.

Learn More

Boost productivity with Mixers built for heavy-duty processing. Designed for consistent performance, they ensure efficient material blending and reduce operational costs with minimal maintenance.

Learn More

Achieve uniform material blends with our robust blenders. Engineered for precision and efficiency, they handle tough applications and minimize downtime.

Learn More

Breathe easy with our dust control systems. We'll keep your air clean and your operation running smoothly, so you can focus on what you do best.

Learn MoreMaterial Handling Systems

Pneumatic Conveying

We'll help you navigate the complexities of dilute and dense phase conveying, tailoring a solution that maximizes efficiency, minimizes downtime, and keeps your operation running smoothly.

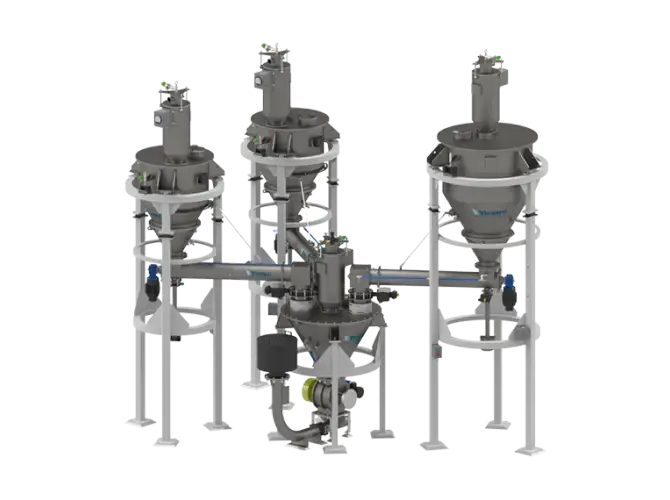

Weighing & Batching

Our batch weighing systems contribute to processing efficiencies by reducing material waste, optimizing line speed and capacity, and helping provide a safe operator work environment.

Key Advantages

Experienced

We have over 75 years of industrial expertise.

Responsive

We always reply to client queries within 24 hours.

Technology

We use advanced technology in all of our projects.

Manufacturing Services

We don’t just build to spec; we innovate with cutting-edge fabrication and streamlined processes to exceed expectations.

We don't just follow specifications, we optimize. Our engineers use their expertise to create high-performance, long-lasting solutions.

We don't just analyze, we solve. Our lab team partners with you to overcome material challenges, boost efficiency and enhance your processes.

We don't just repair, we revitalize. Our team restores your equipment to like-new condition, extending its lifespan and maximizing performance.

Resources

We're more than just equipment manufacturers – we're your material handling problem-solving partners. Our resources section is packed with valuable information to help you optimize your processes, troubleshoot issues, and stay ahead of the competition.