INTRO: TransFlow® Technology

DEMO: TransFlow® Aeration Pads

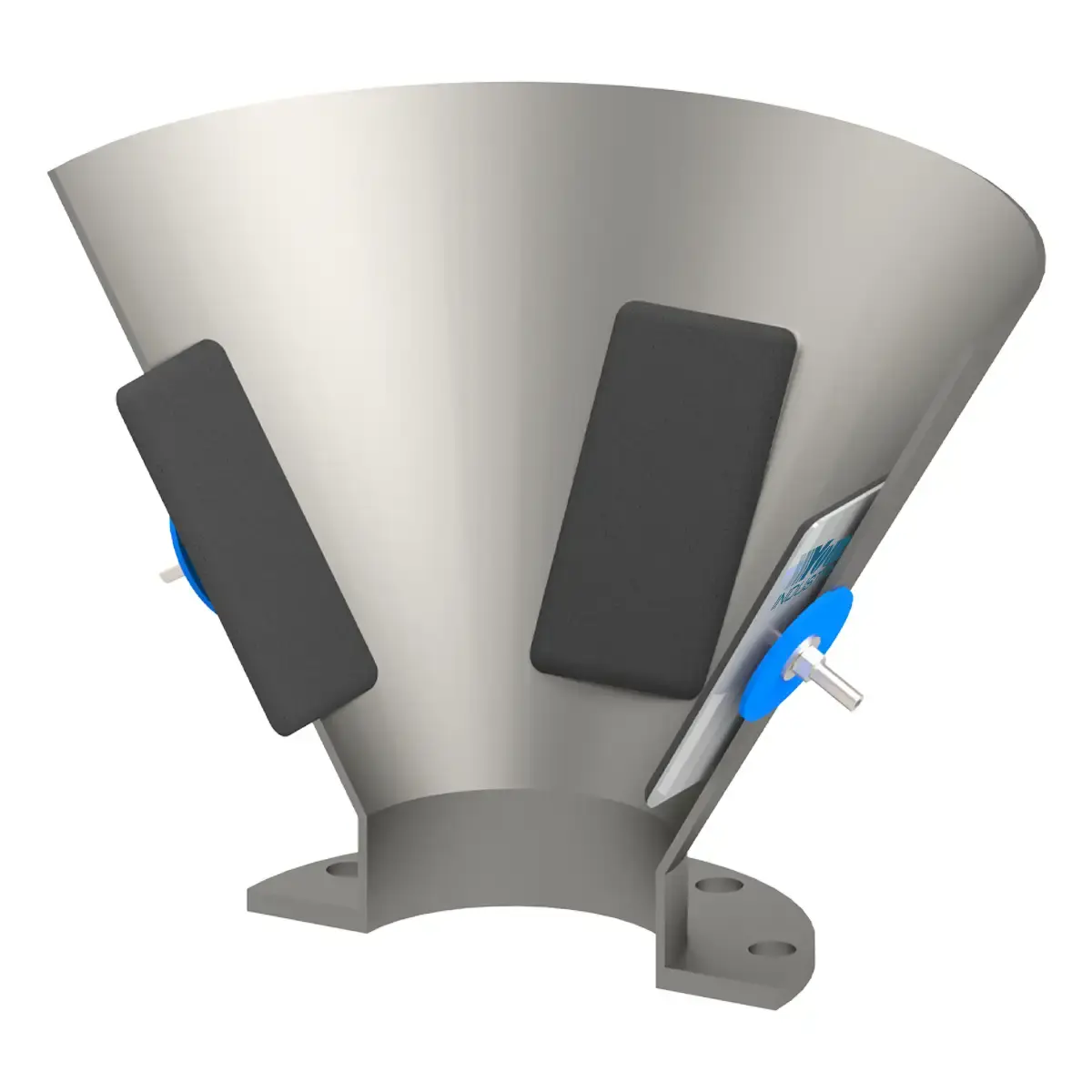

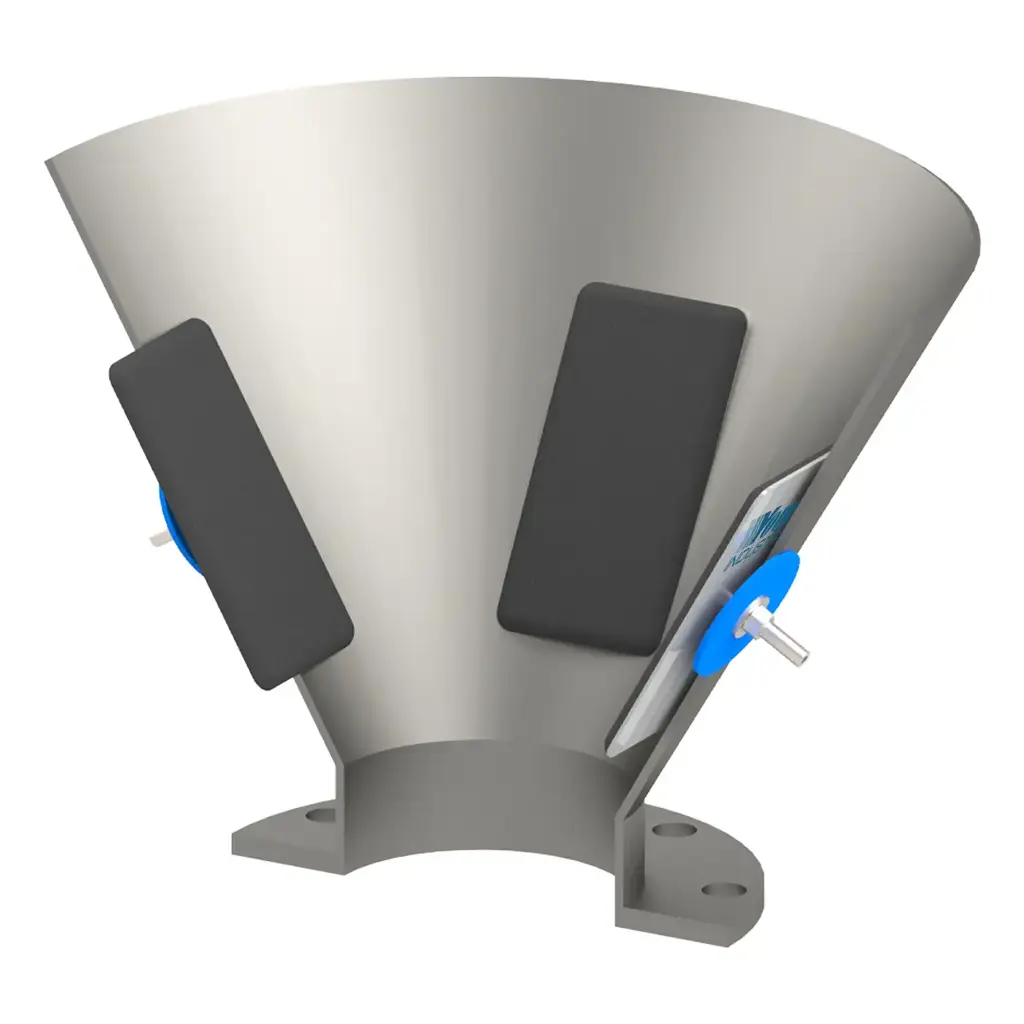

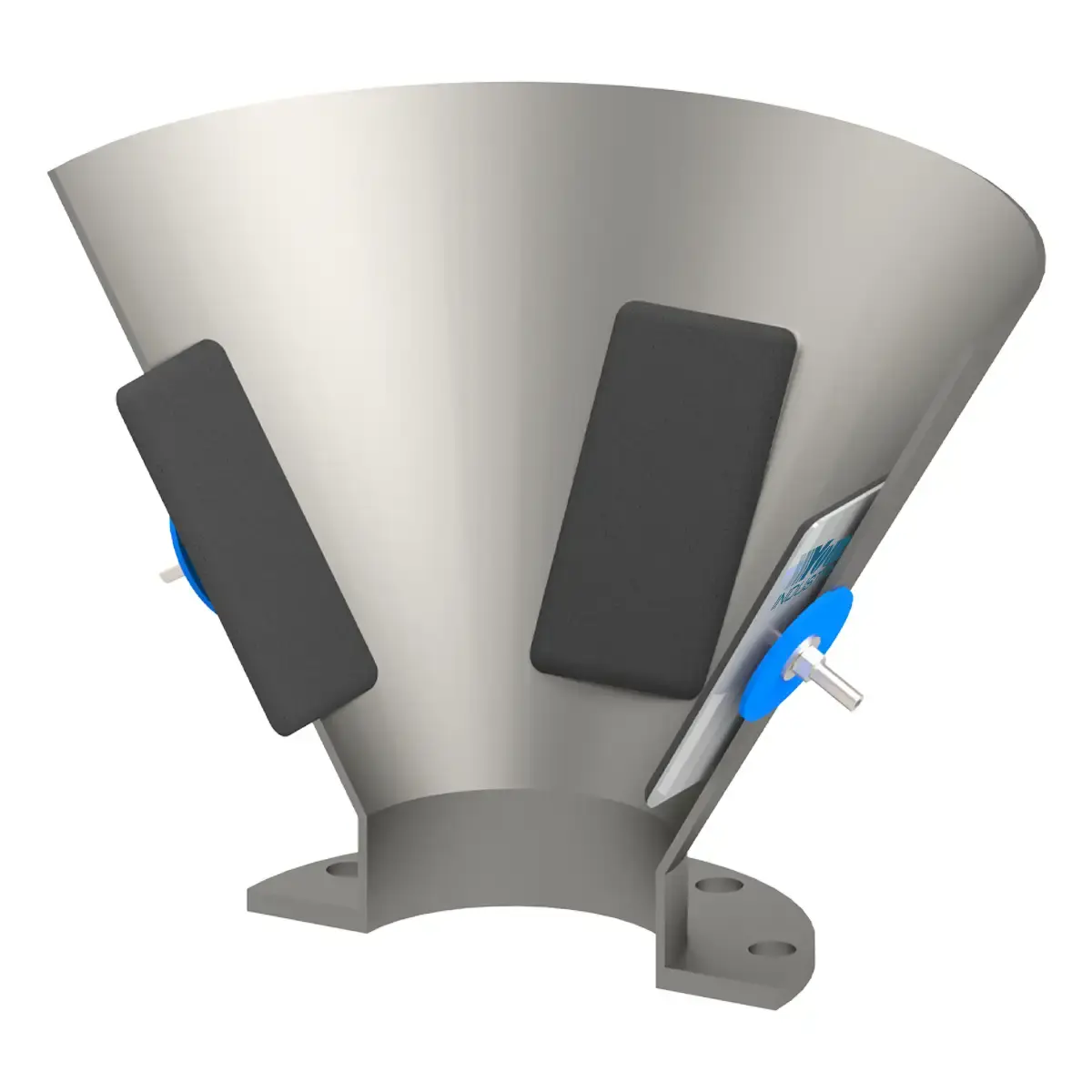

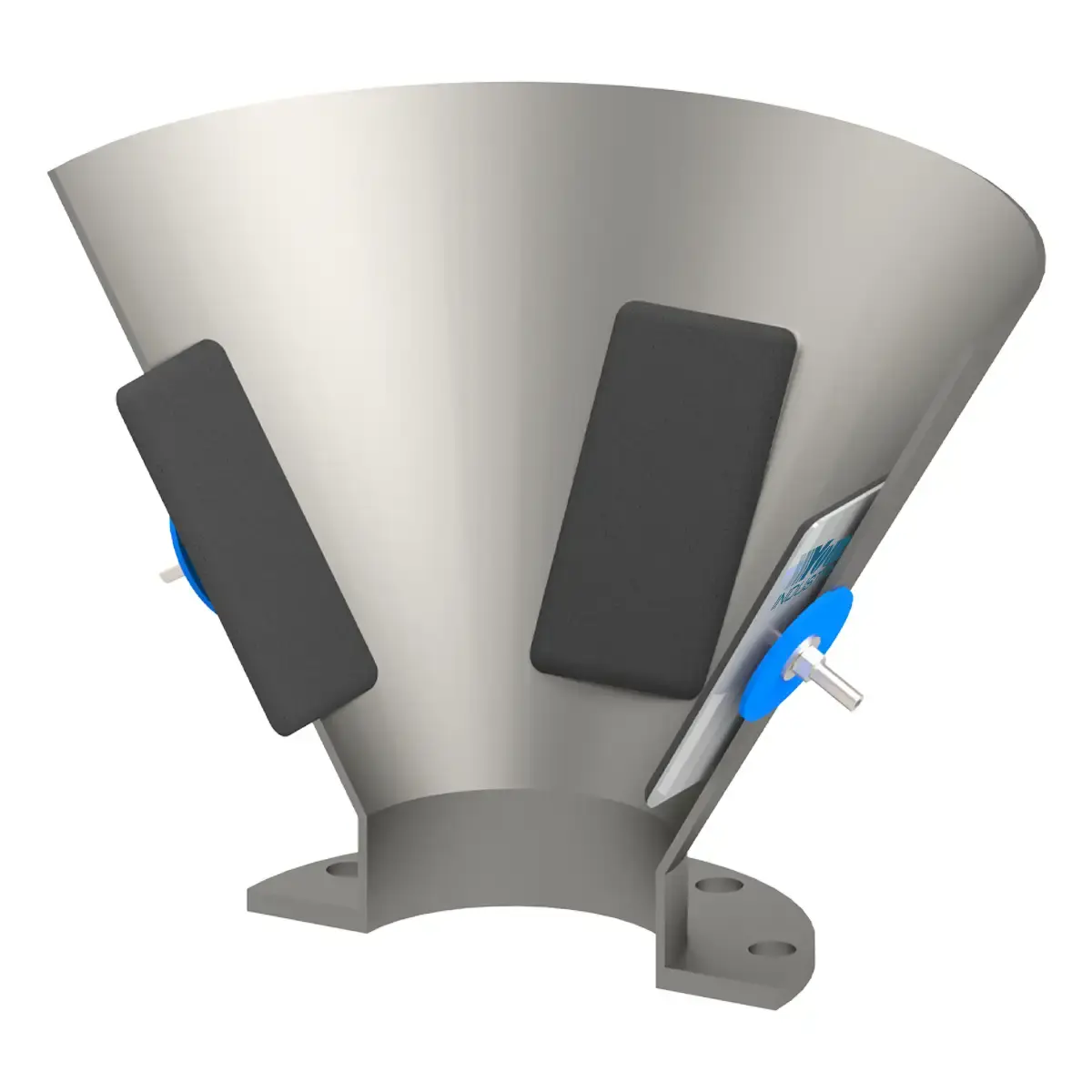

TransFlow® Pads

TransFlow® Pads are, hands-down, more efficient than other methods of fluidization. Our patented design and all-welded construction ensure superior efficiency and durability, even in the harshest industrial environments. These pads uniformly distribute air or gas, transforming sluggish materials like lime, flour, soda ash, and more into a fluid-like state for effortless discharge.

Features & Options

TransFlow Pads represent a breakthrough in fluidization technology, engineered to deliver unmatched performance and reliability when fluidizing fine powders. The reason is simple: TransFlow’s contact surface finish, internal baffles and all-welded design ensure smooth, consistent flow from hoppers, bins, and silos. Our team of master welders make the pads virtually indestructible by continuously fusing the fluidizing media to the back plate.

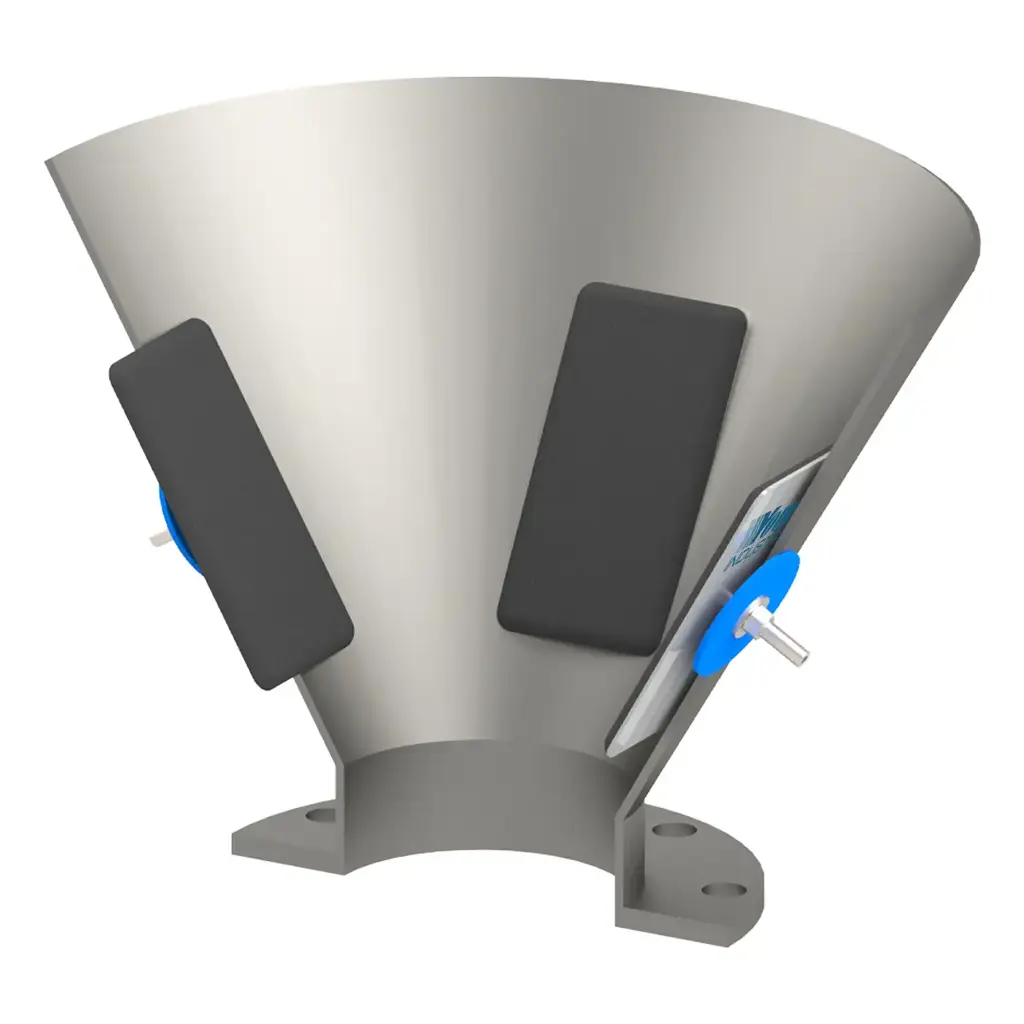

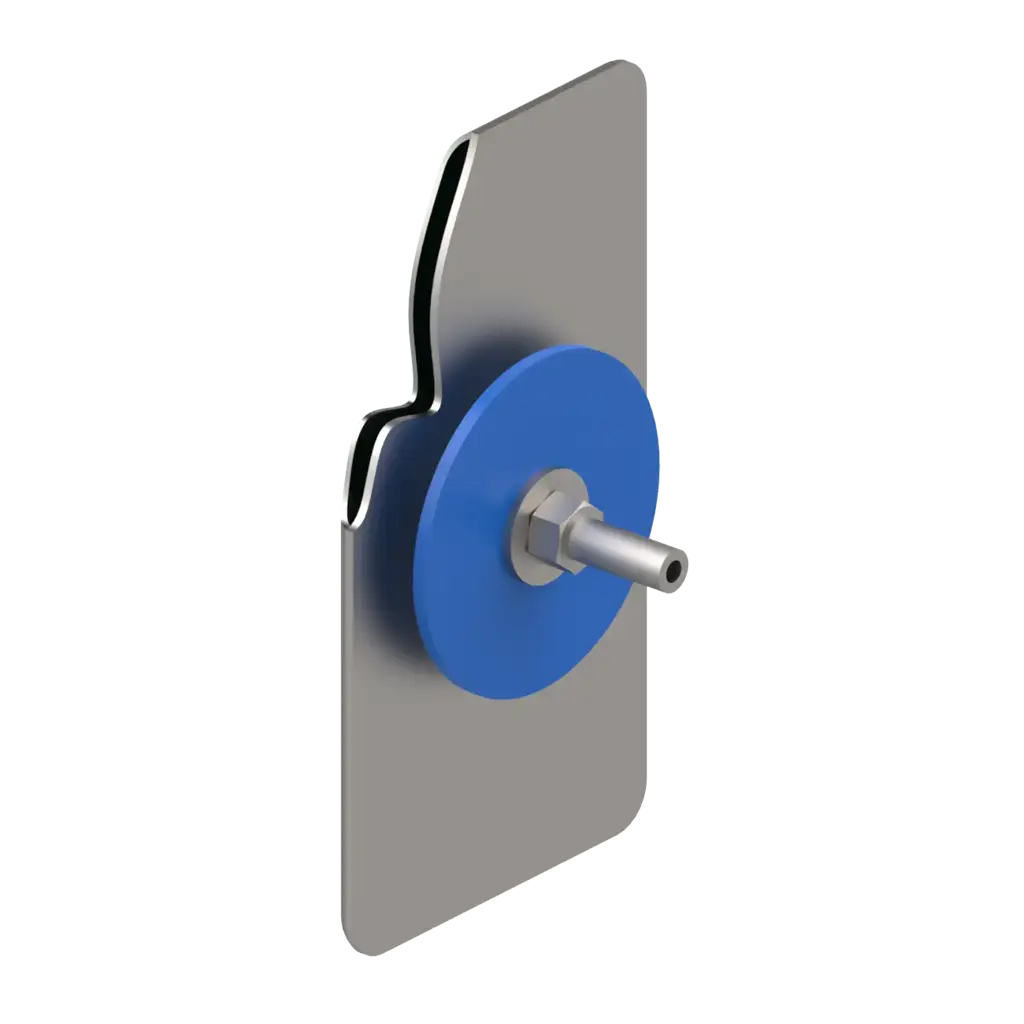

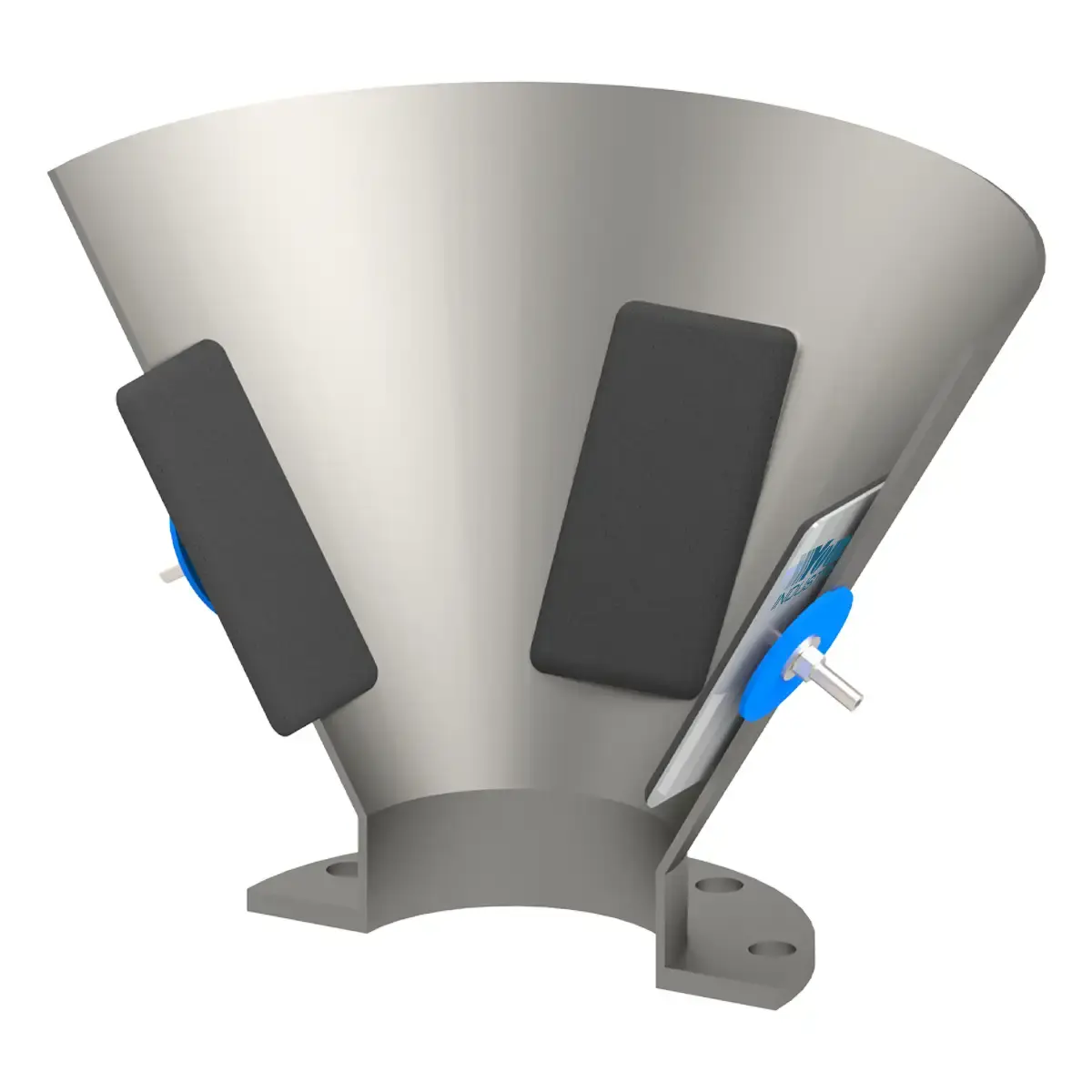

Depending on your material and hopper slope, multiple pads may be needed. Our team of fluidization experts can help you determine the optimal placement for maximum efficiency. From there, installation is simple – just drill a hole, insert the pad, and secure it with the provided hardware.

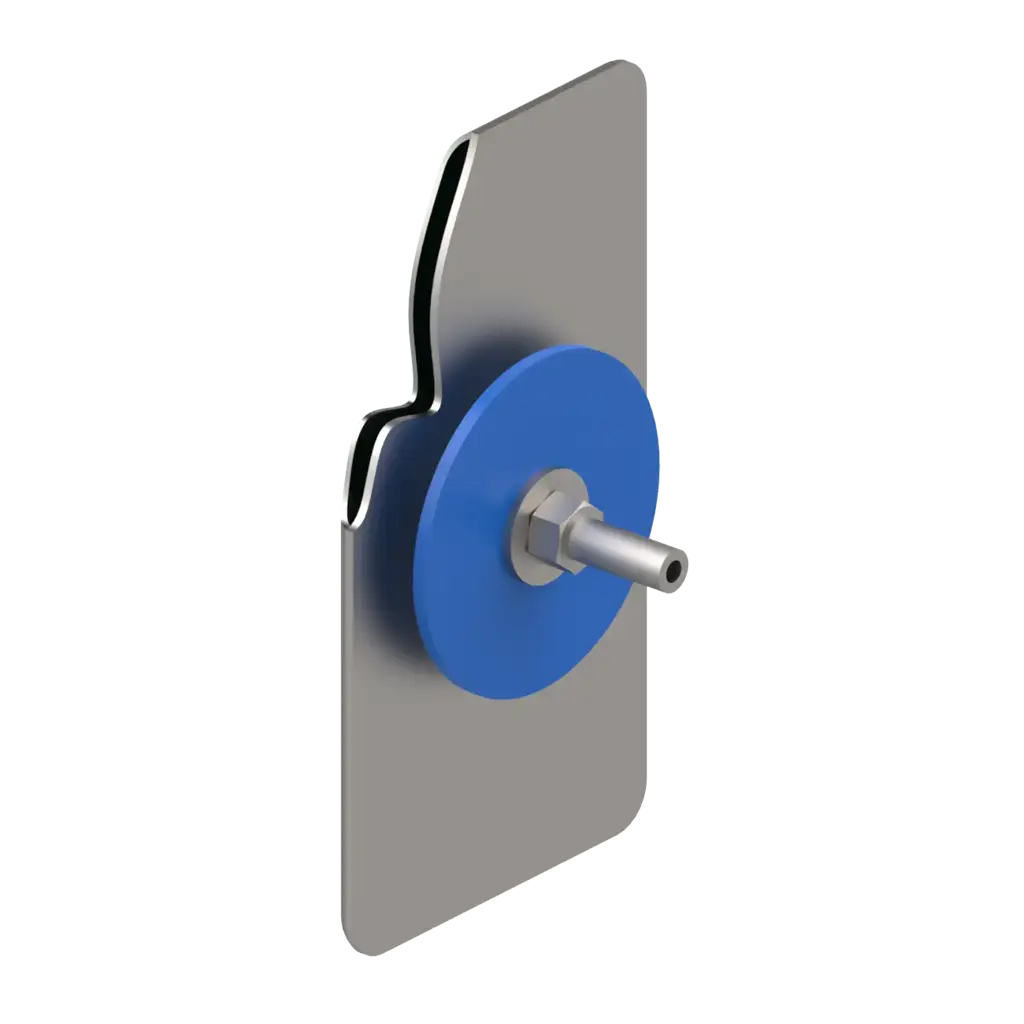

The air pad is constructed with The Young Industries, Inc. TransFlow® aeration media. This media is constructed of multilayer wire mesh with a finished contact surface that produces smooth, evenly distributed airflow. This finished product produces a layer of air that suspends the bulk material from the media, making it easy for the material to slide.

The TransFlow® Pad is more efficient than traditional fluidization technologies because of its internal baffles and all-welded design. The fluidizing media is welded seamlessly to the back plate. This provides 15% more surface area compared to crimped pad designs.

Unlike other aeration devices that use cotton or fiberglass diffuser materials, TransFlow® Aeration Pads can be cleaned chemically or with steam, water, or compressed air. Plus, they dry quickly. Unlike aeration devices that use plastic or rubber boots and covers, TransFlow® Aeration pads are extremely durable and long-lasting. They are corrosion resistant and will never flake, chip, or degrade. In fact, they are "almost" indestructible. But if you ask us, that "almost" is just for the lawyers.

- Material: AISI type 316 stainless steel fluidizing media with type 304 stainless steel back and plated steel threaded pipe

- Operating temperature: Up to 1000° F

- Corrosion and oxidation resistance: Excellent

- Strength: much stronger than other fluidizing media. Resistant to abrasion and puncture. Substantially better than cotton and fiberglass fiber composites or powder metal or plastic covered products

- SIZES: Two sizes available to handle most application requirements

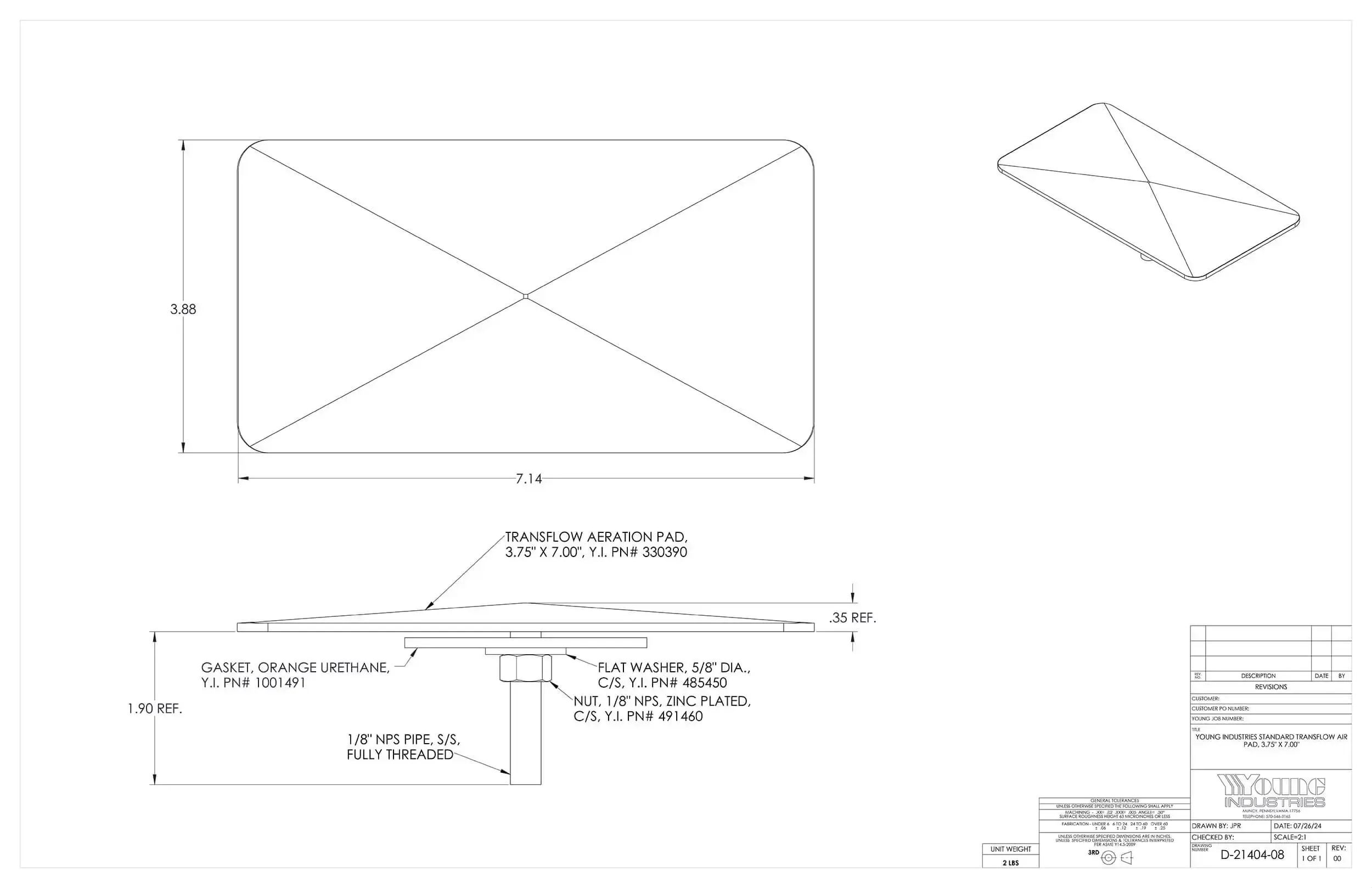

- 3.88” wide x 7.15” long x .31” high with 1/8” NPS Pipe connection

- 4” wide x 12” long x .35” high with 1/8” NPS pipe connection

- TransFlow® pads are normally in stock for immediate shipment

- Air or gas piping system with controls

- Compressor or PD blower units

- Pneumatic or mechanical conveying system or components

- Custom sizes available on request

Specifications

| Dimensions | Material of Construction | Max Operating Temperature | Standard Design Pressure | Air Supply Requirements |

|---|---|---|---|---|

| 3.75" wide x 7" long x .31" high complete with 1/8" thread pipe, 2" long. | 304 Stainless Steel (316 Stainless Steel Transflow) | 1000°F | .63 PSIG Internal / External | 5 to 10 SCFM (3-15 PSIG recommended, 50 PSIG Max.) |

| 4.00" wide x 12" long x .31" high complete with 1/8" thread pipe, 2" long. |