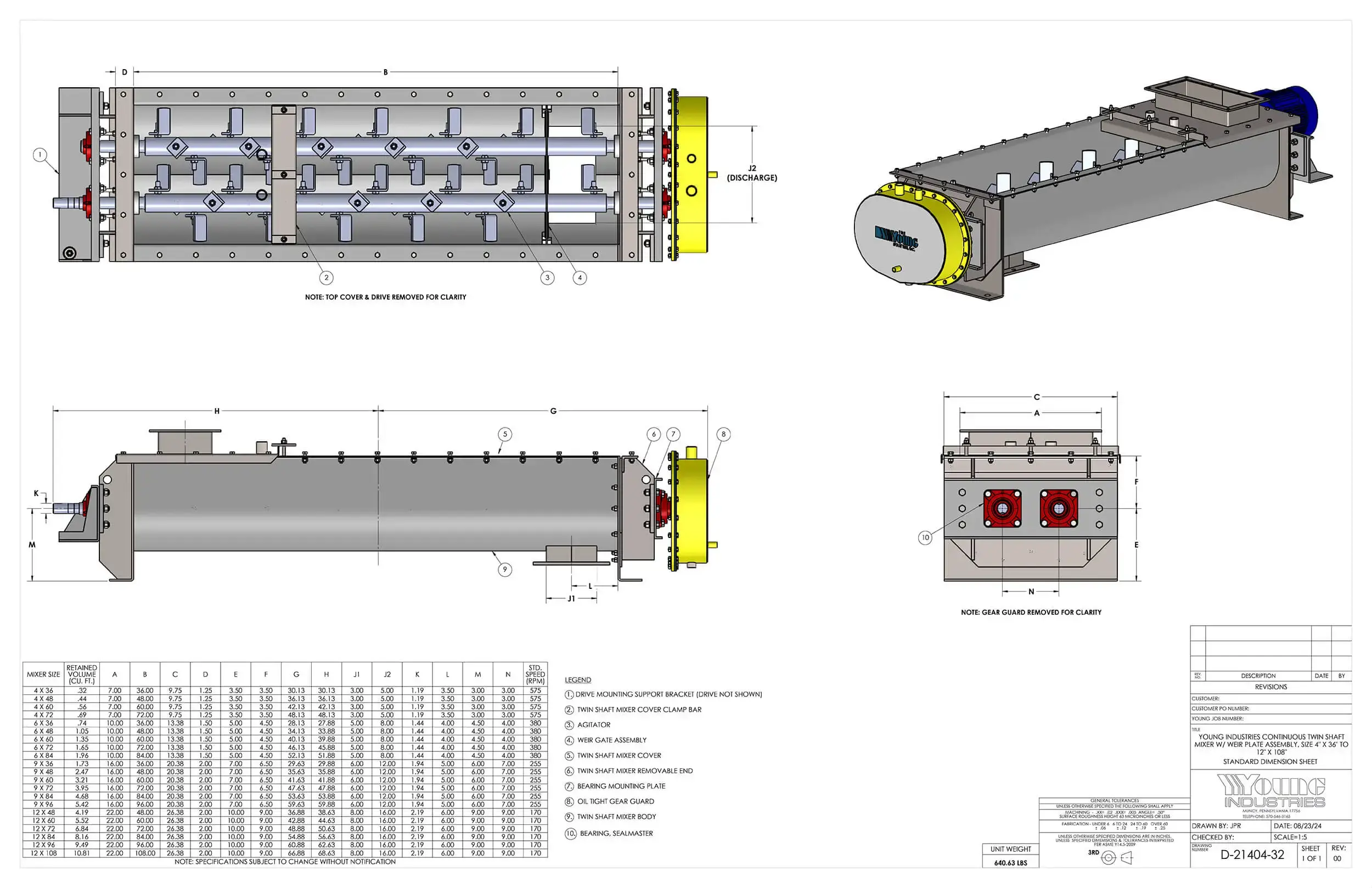

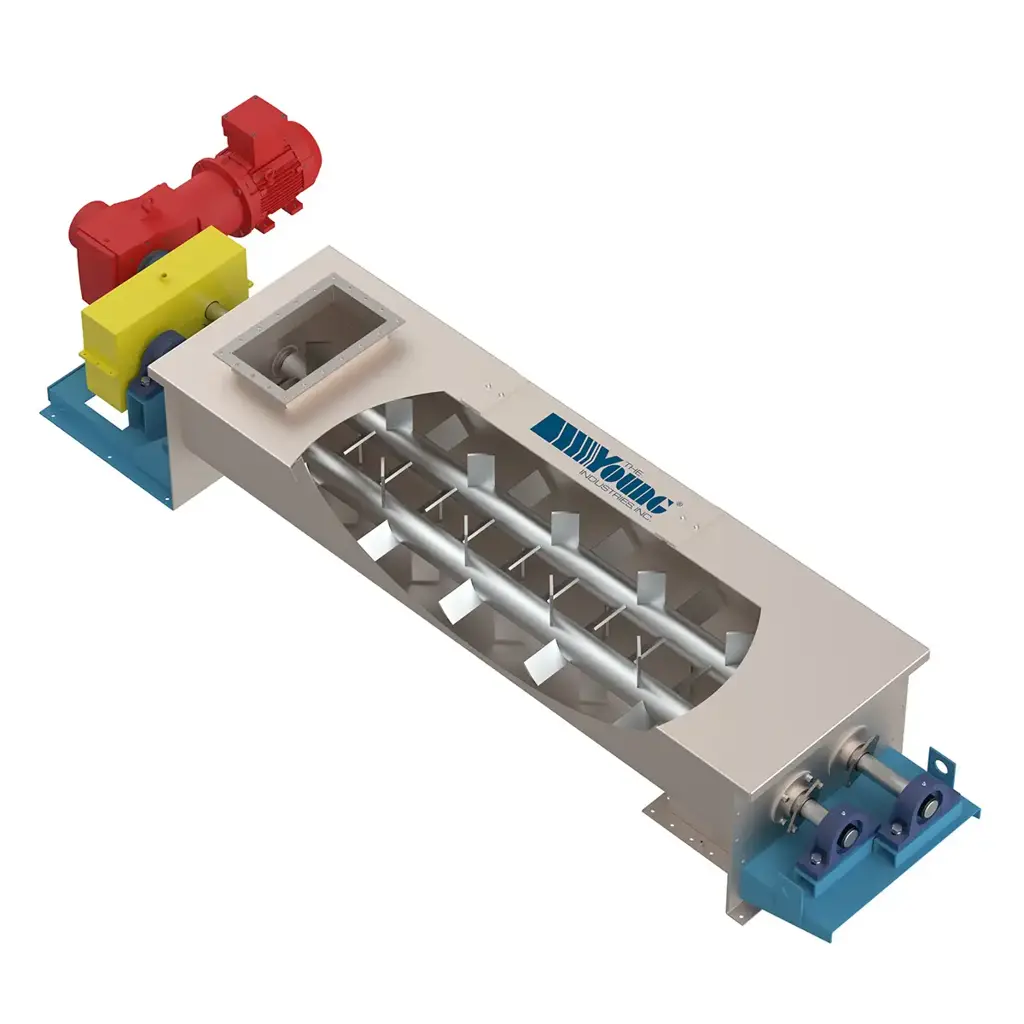

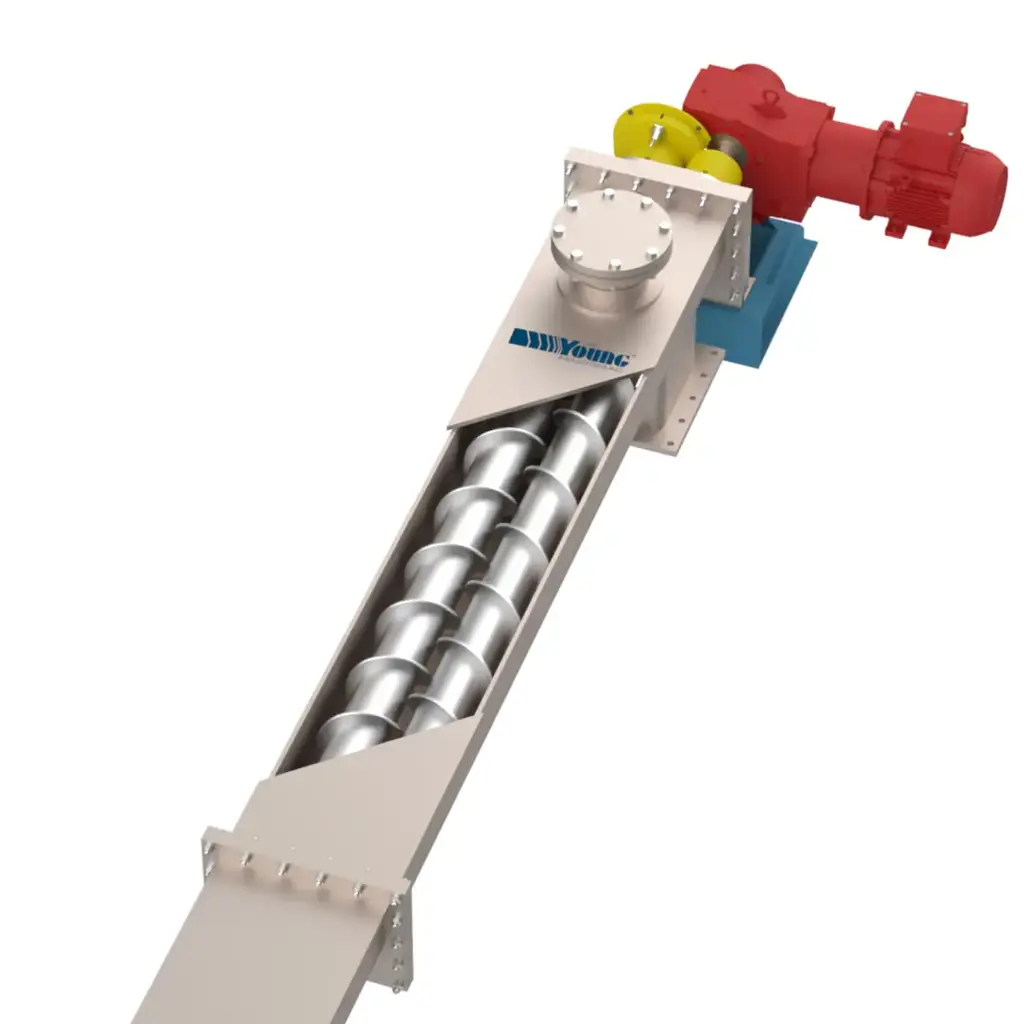

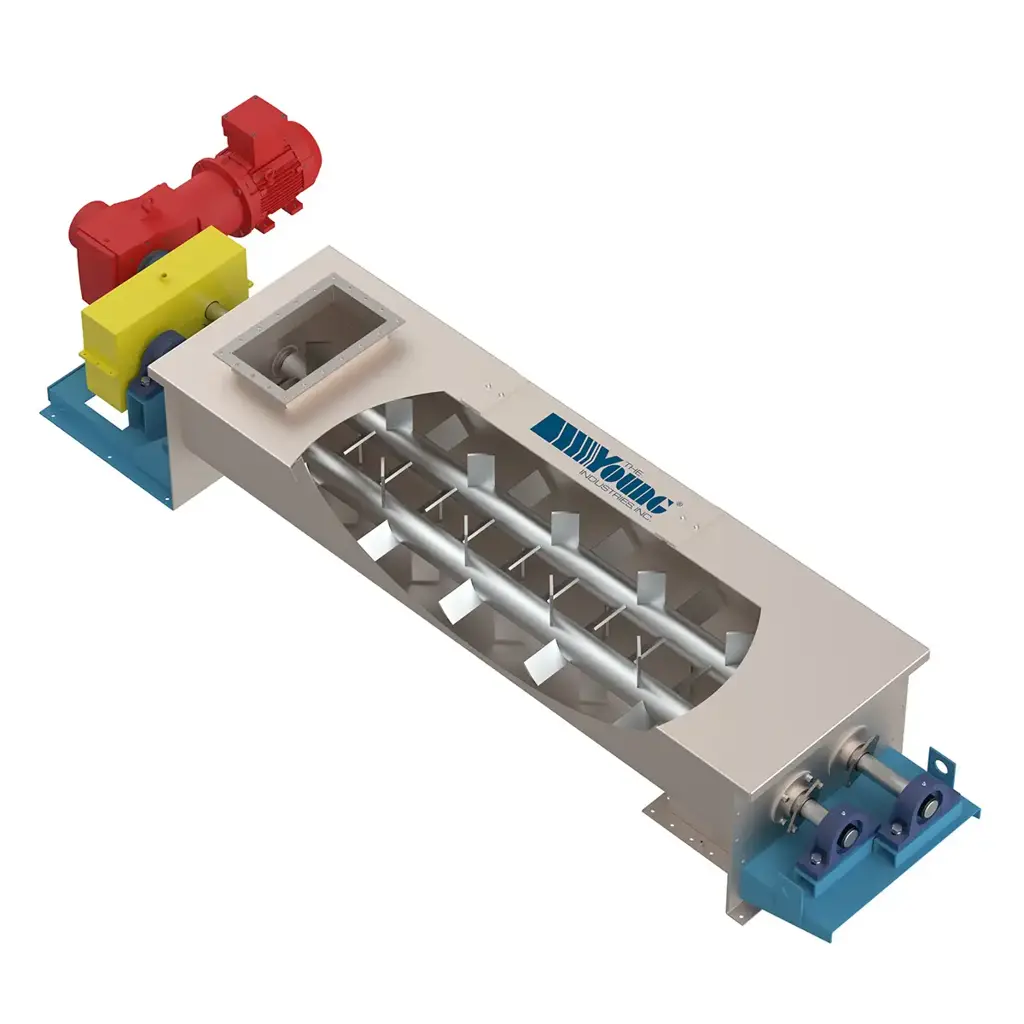

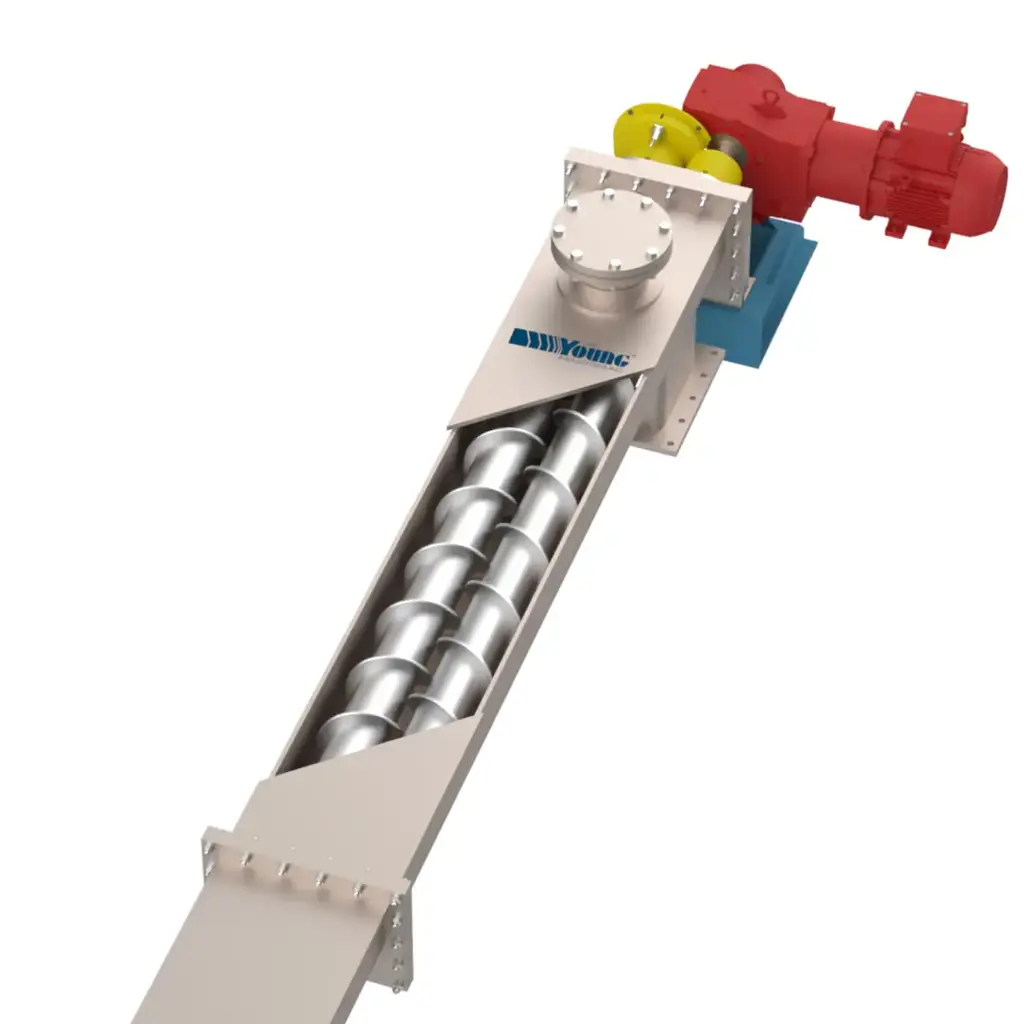

Twin-Shaft Continuous Mixer

Young Industries Twin-Shaft Mixers are engineered for continuous, high-performance blending of a wide range of materials, from powders and liquids to pastes. These versatile mixers are trusted across a range of industries, including petrochemical, chemical, ceramics, food, and waste treatment.

Whether you're blending delicate ingredients, handling abrasive materials, or processing high-viscosity pastes, we have the expertise and technology to deliver a mixer that meets your exact requirements.

Features & Options

When it comes to continuous mixing, efficiency and adaptability are key. Our Twin-Shaft Continuous Mixers are engineered from the ground up to deliver exceptional performance, while offering a range of customizable features to meet the unique demands of your process and application.

We offer a variety of options to optimize your process, including spray manifolds for liquid dispersion, weir gate for controlled material retention, and multiple inlets for powder addition.

- All-welded construction

- One removable end for removing agitators

- Fixed pitch paddle agitators

- Double "U" trough design

- Outboard, anti-friction bearings

- Renewable packing glands

- Structural covers, gasketed and hinged

- High pressure or vacuum

- Explosion proof motor

- Packing gland with purge connection & lantern ring

- Carbon steel or 300 series stainless steel construction

- Exterior jackets for heating or cooling

- ASME exterior jackets available

- Fixed or adjustable paddles

Specifications

| Mixer Size (Diameter x Length) | Retained Volume (cubic feet) | Overall Length (in.) | Overall Width (in.) | Overall Height (in.) | Standard Speed (RPM) |

|---|---|---|---|---|---|

| 4 x 36 | 0.32 | 60.25 | 9.75 | 7 | 575 |

| 4 x 48 | 0.44 | 72.25 | |||

| 4 x 60 | 0.56 | 84.25 | |||

| 4 x 72 | 0.69 | 96.25 | |||

| 6 x 36 | 0.74 | 56 | 13.38 | 9.5 | 380 |

| 6 x 48 | 1.05 | 68 | |||

| 6 x 60 | 1.35 | 80 | |||

| 6 x 72 | 1.65 | 92 | |||

| 6 x 84 | 1.96 | 104 | |||

| 9 x 36 | 1.73 | 59.5 | 20.38 | 13.5 | 255 |

| 9 x 48 | 2.47 | 71.5 | |||

| 9 x 60 | 3.21 | 83.5 | |||

| 9 x 72 | 3.95 | 95.5 | |||

| 9 x 84 | 4.68 | 107.5 | |||

| 9 x 96 | 5.42 | 119.5 | |||

| 12 x 48 | 4.19 | 75.5 | 26.38 | 19 | 170 |

| 12 x 60 | 5.52 | 87.5 | |||

| 12 x 72 | 6.84 | 99.5 | |||

| 12 x 84 | 8.16 | 111.5 | |||

| 12 x 96 | 9.49 | 123.5 | |||

| 12 x 108 | 10.81 | 135.5 | |||

| 15 x 72 | 10.2 | 101.75 | 31 | 22 | 155 |

| 15 x 84 | 12.3 | 113.75 | |||

| 15 x 96 | 14.4 | 125.75 | |||

| 15 x 108 | 16.5 | 137.75 | |||

| 15 x 120 | 18.5 | 149.75 | |||

| 15 x 132 | 20.6 | 161.75 | |||

| 18 x 96 | 17 | 130.75 | 40 | 25 | 125 |

| 18 x 120 | 22 | 154.75 | |||

| 18 x 144 | 27 | 178.75 | |||

| 18 x 168 | 32 | 202.75 | |||

| 18 x 192 | 37 | 226.75 | |||

| 18 x 216 | 42 | 250.75 | |||

| 21 x 120 | 29.3 | 158.75 | 45 | 30 | 110 |

| 21 x 144 | 36 | 182.75 | |||

| 21 x 168 | 42.8 | 206.75 | |||

| 21 x 192 | 49.6 | 230.75 | |||

| 21 x 216 | 56.4 | 254.75 | |||

| 21 x 240 | 63.2 | 278.75 | |||

| 24 x 120 | 39.4 | 115.25 | 52 | 34 | 85 |

| 24 x 144 | 48.6 | 139.25 | |||

| 24 x 168 | 57.9 | 163.25 | |||

| 24 x 192 | 67.1 | 187.25 | |||

| 24 x 216 | 76.4 | 211.25 | |||

| 24 x 240 | 85.62 | 235.25 | |||

| 30 x 120 | 62.45 | 167.75 | 63 | 42 | 65 |

| 30 x 144 | 77.25 | 191.75 | |||

| 30 x 168 | 92.05 | 215.75 | |||

| 30 x 192 | 106.86 | 239.75 | |||

| 30 x 216 | 121.66 | 263.75 | |||

| 30 x 240 | 136.46 | 287.75 | |||

| 36 x 120 | 91.5 | 171.25 | 75 | 50 | 60 |

| 36 x 144 | 111.6 | 195.25 | |||

| 36 x 168 | 135.7 | 219.25 | |||

| 36 x 192 | 157.8 | 243.25 | |||

| 36 x 216 | 181.81 | 267.25 | |||

| 36 x 240 | 202.1 | 291.25 |

Customization

Need a Twin-Shaft Continuous Mixer that's perfectly tailored to your process? Whether it's a specific agitator design, specialized spray manifolds, or precise controls, we'll work with you to create the ideal solution. Ready to explore the possibilities?