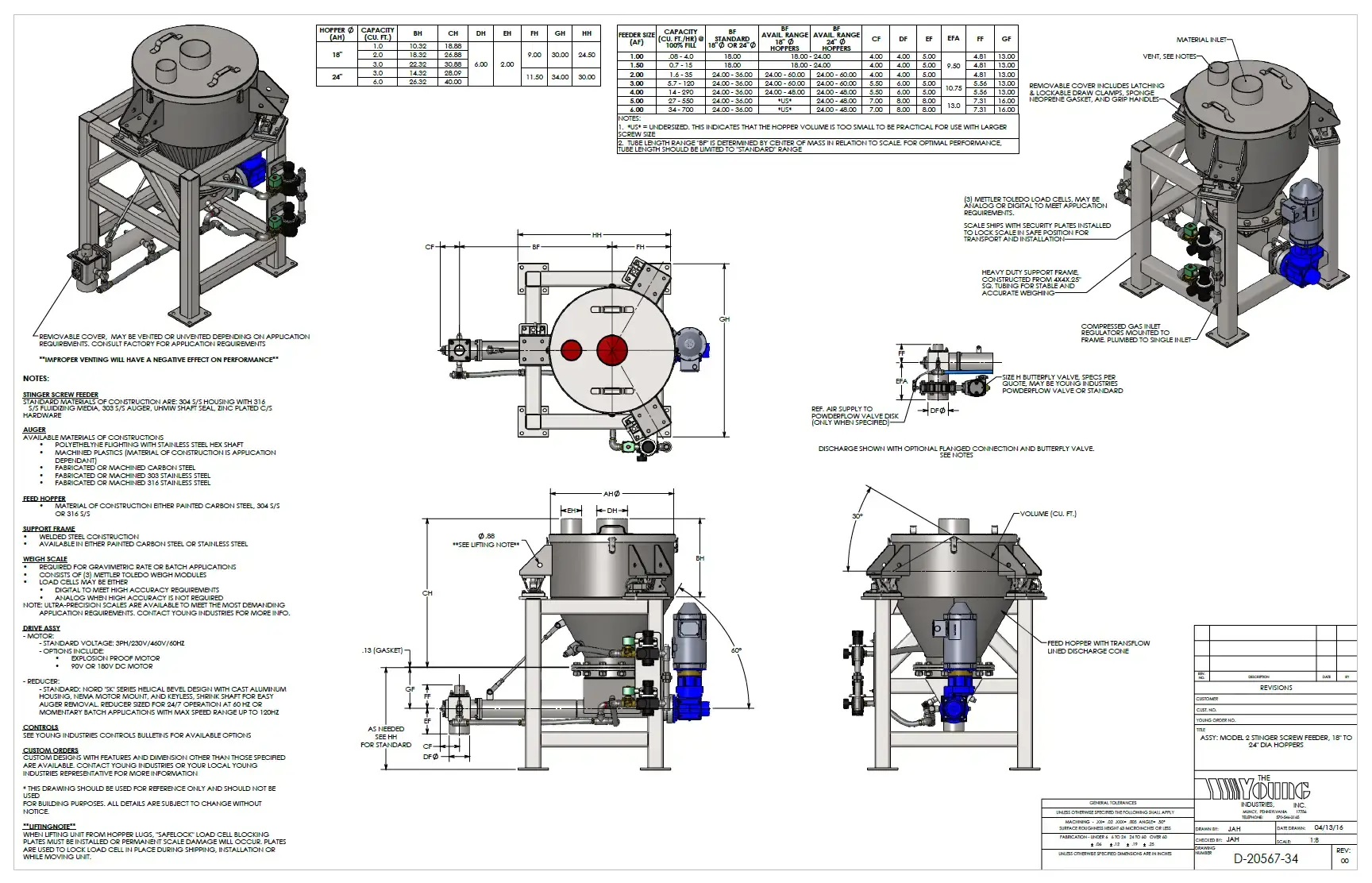

Model STS-1 Feeder

The Model STS-1 Feeder combines our Stinger tube, auger, support frame, and hopper into a single, rugged weldment design. This feeder is built for versatility, handling batch feeding, continuous gravimetric feeding, or volumetric feeding with ease.

We've designed the STS-1 to work seamlessly with our TOUCHSTONE controllers, giving you precise control over your feeding process. Whether you need batch control, continuous control, or volumetric control, we've got you covered.

Model STS-2

Need a feeder that can adapt to your changing needs? The Model STS-2 Feeder features a modular design that makes it easy to configure and reconfigure as your requirements evolve. It's the perfect solution for batch feeding, continuous gravimetric feeding, or volumetric feeding, all in one economical package.

Like our other Stinger® Feeders, the STS-2 is designed to work seamlessly with our TOUCHSTONE controllers, giving you precise control over your feeding process, including batch, continuous, and volumetric control.