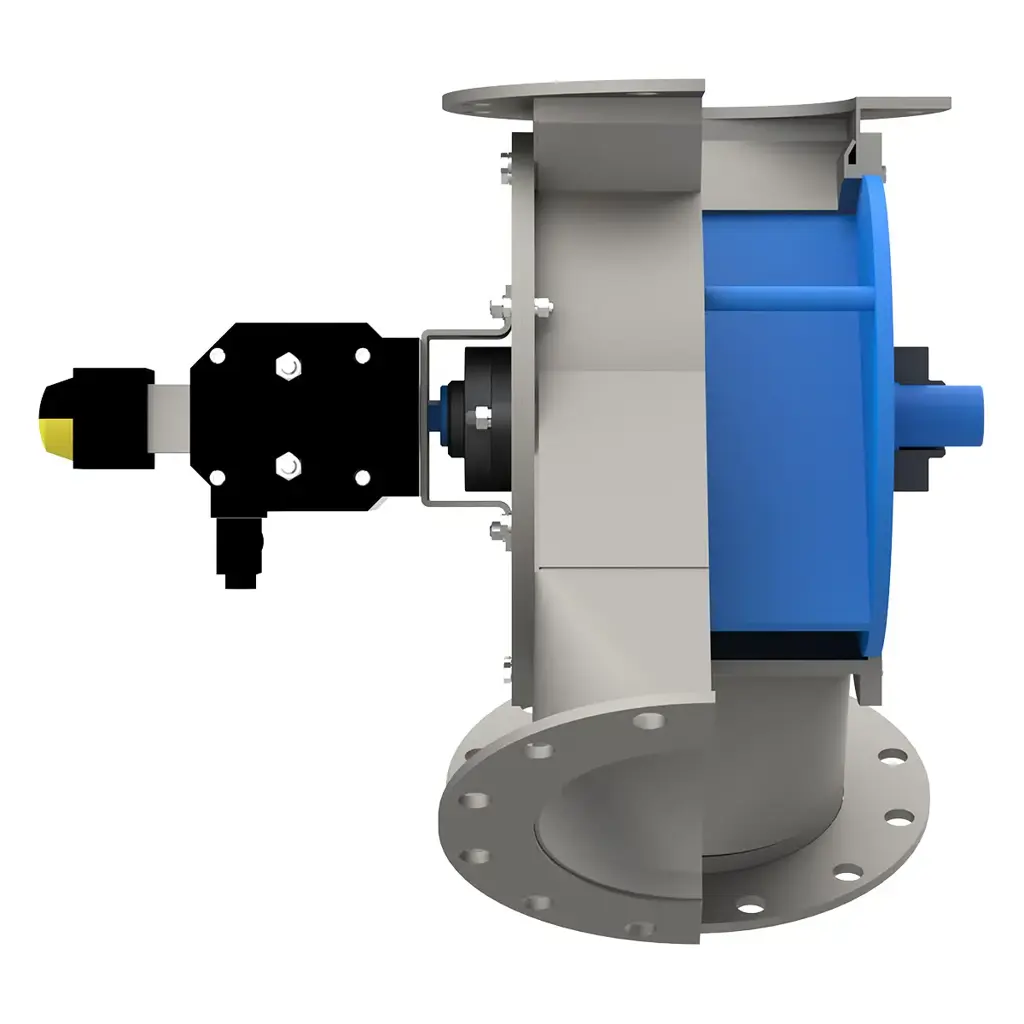

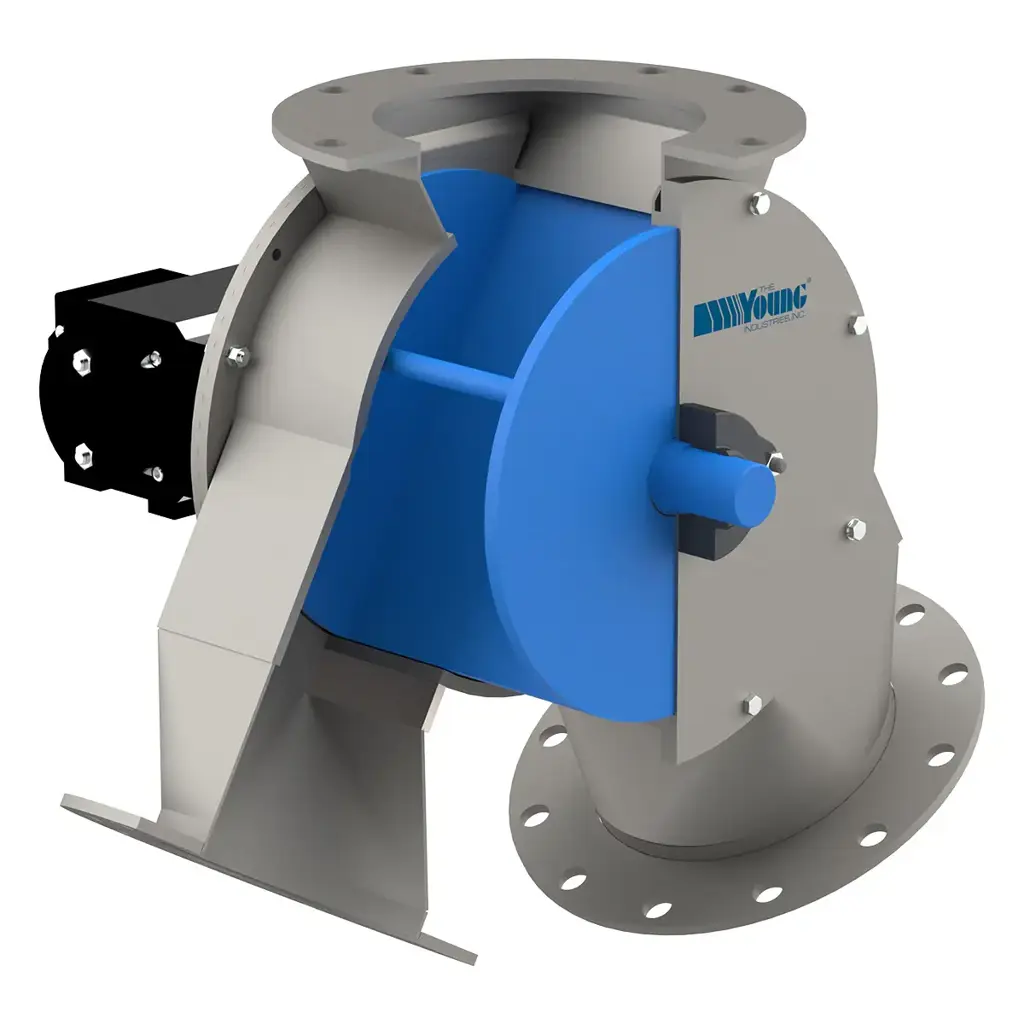

Rotary Vane

Model VT Diverter

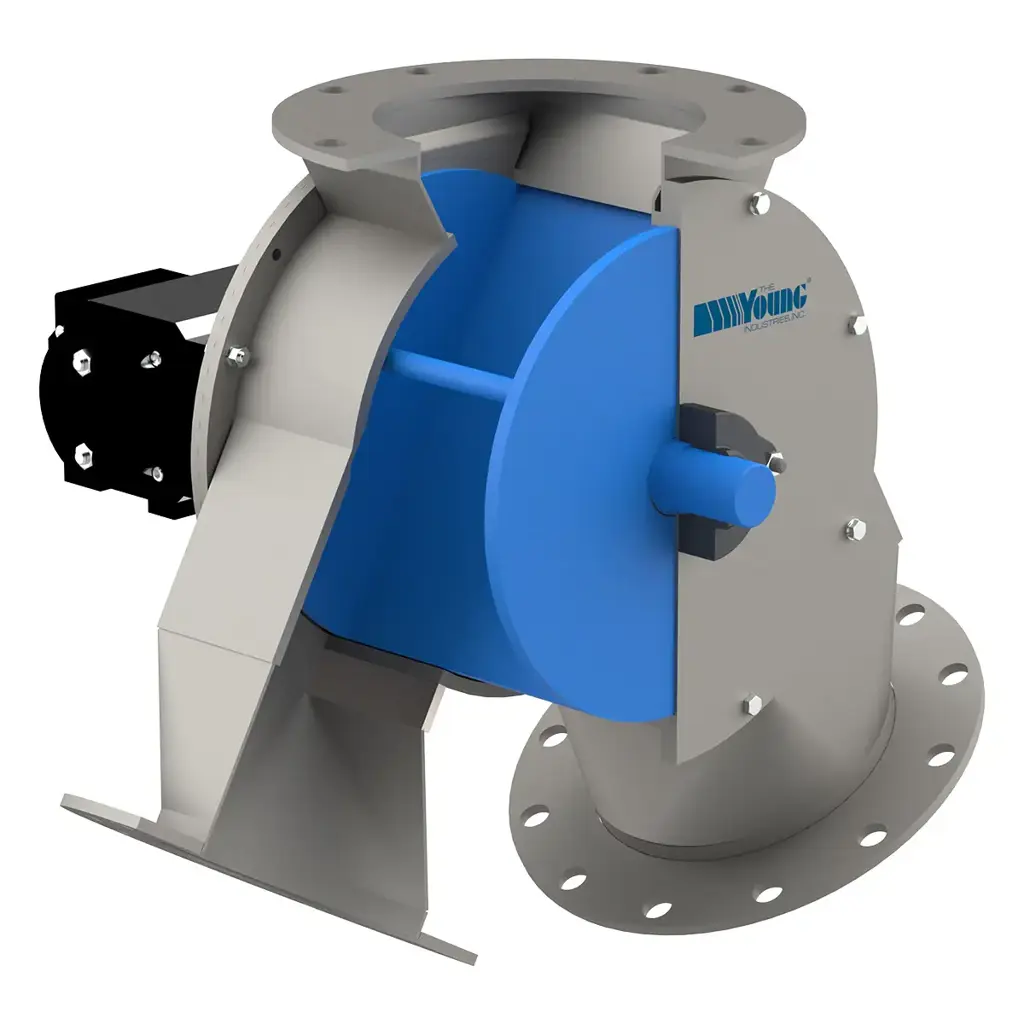

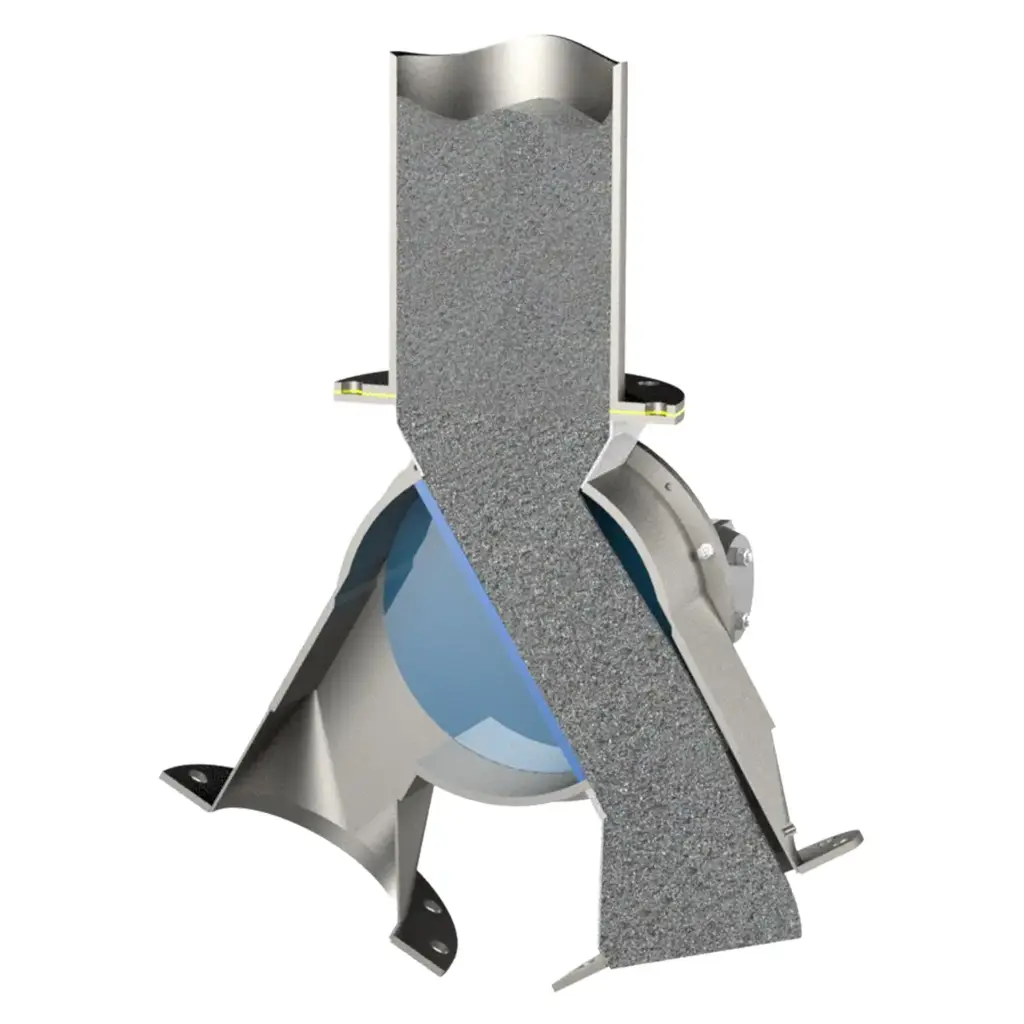

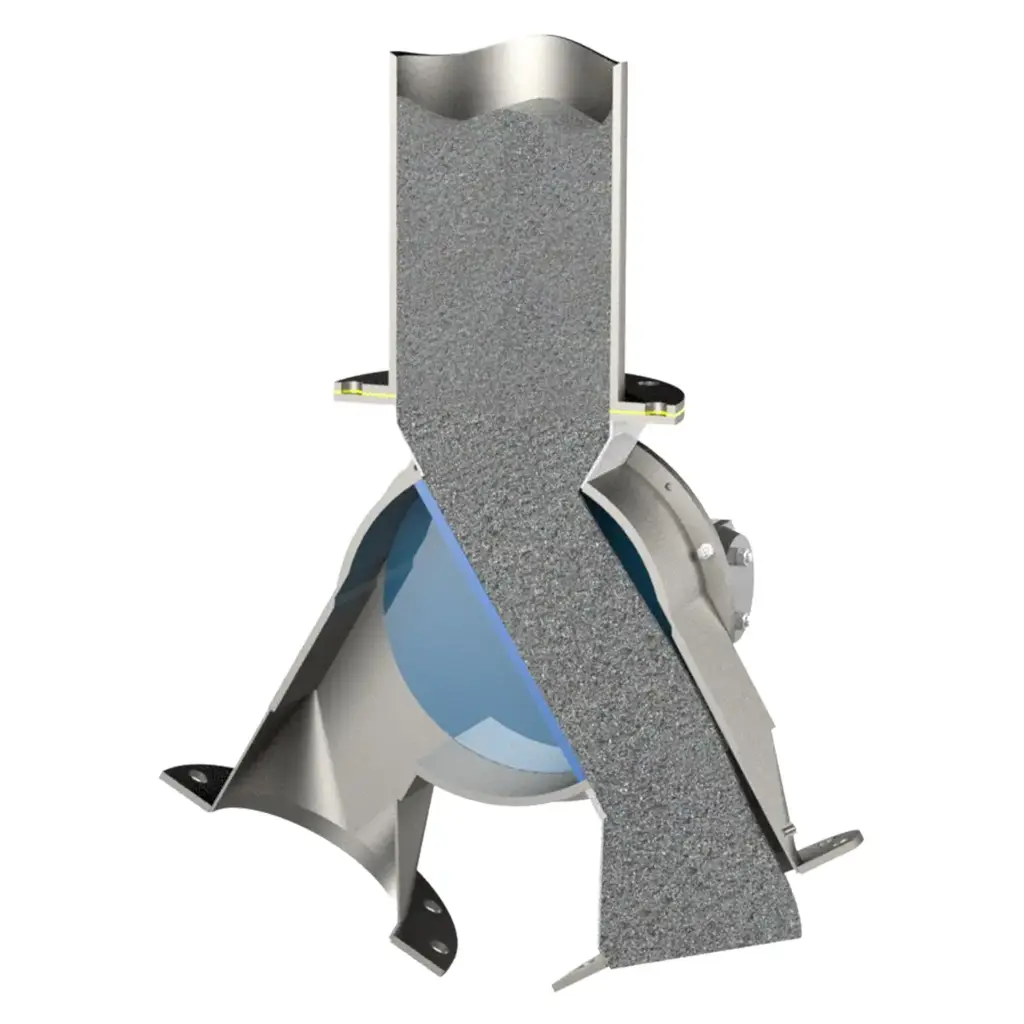

Young Industries' Rotary Vane Diverter Valves are expertly engineered to handle your dry bulk material needs with precision and efficiency. Designed for gravity flow applications where minimal leakage is acceptable, these valves offer exceptional performance and adaptability.

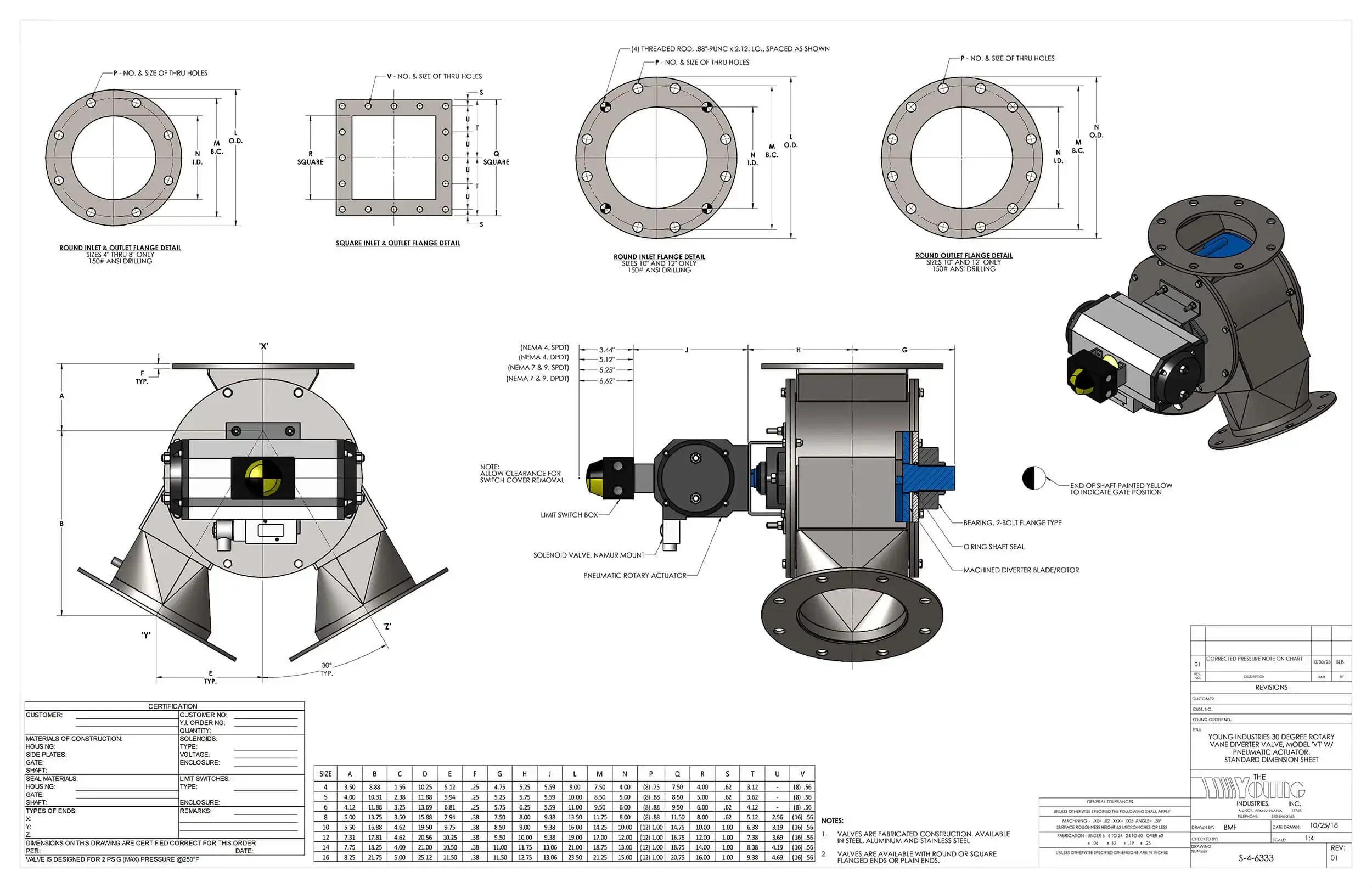

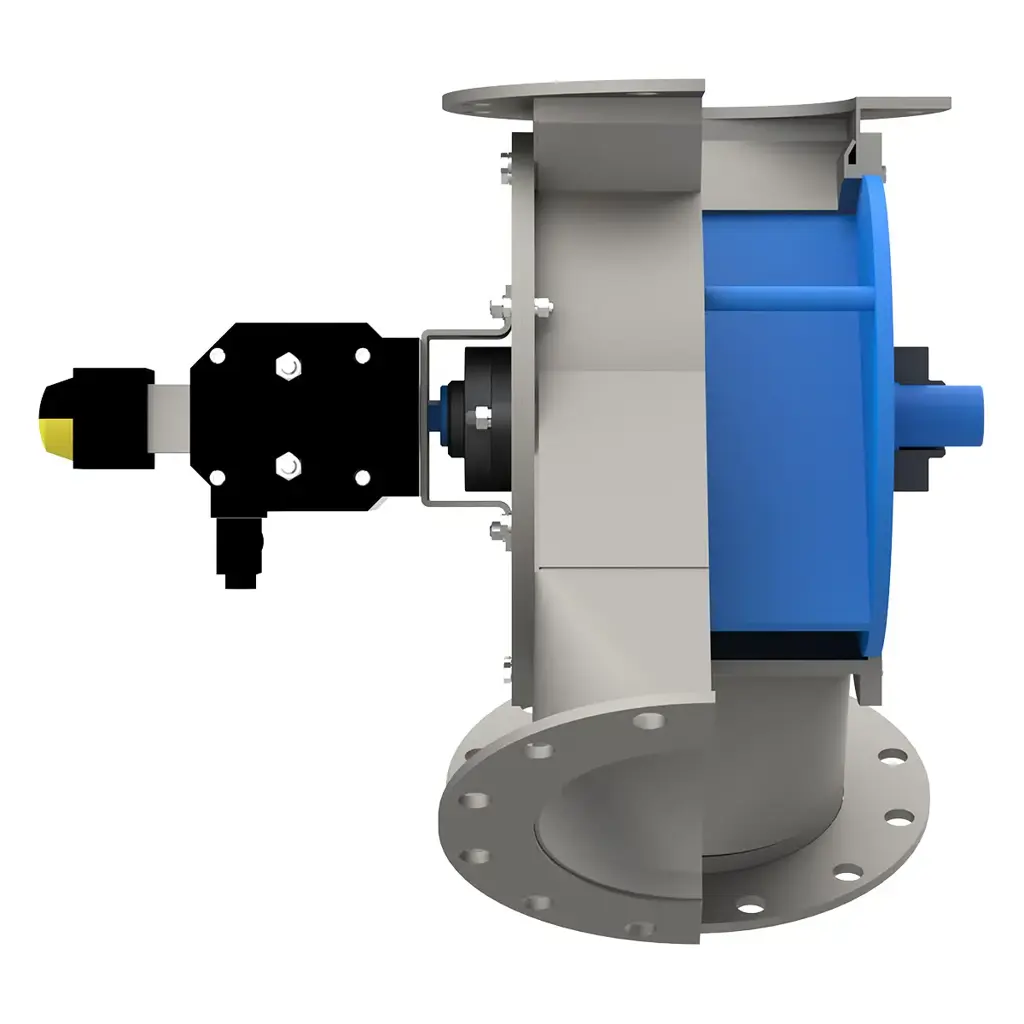

Their robust design features flange-mounted bearings for smooth operation, and O-ring seals minimize dust leakage. This translates to longer service life and lower maintenance costs. The valve’s actuator is direct coupled to the vane shaft. This arrangement distributes torque directly to the vane shaft, eliminating stress to the valve components.

Features & Options

The flexible design allows you to tailor the Rotary Vane Diverter Valve to your specific application requirements, ensuring efficient and reliable material handling. They are used in applications were material needs to be diverted 30° or 45° from the inlet leg. The change of direction is accomplished by changing the position of the vane from one line to the other by a rotary actuator. Choose from a range of features and options to optimize your process.

- 2 PSIG Housing and differential pressure or vacuum

- Available in standard sizes from 4″ through 16″ square flange sizes

- Rotary pneumatic operator, with NEMA 4 single solenoid valves, single-pole double-throw and 2 limit switches – one indicating for each leg

- Electric operator, with 2 limit switches – one switch for each leg

- Materials used include fabricated carbon steel, fabricated stainless steel or fabricated aluminum

- Raw materials are traceable to standard specifications with ASTM the most used specification

- Up to 250°F operation temperature

- Flange mounted precision ball bearings

- Shafts secured to eliminate shifting in the housing

- Grounding and bonding connection to NFPA specifications

- Painted blue epoxy

- Completely assembled and tested

- Round flanges available

- Manual operator

- High pressure design available

- High temperature design available

- Round inlet and outlets with 150 lbs drilling flanges

- Inspection door

- Blade removal without removing from line

- Special sizes available

- Special materials available include 316 stainless steel, Hastelloy, Titanium

- Interior coating to provide abrasive resistance include chrome plating, nickel plating, tungsten carbide, Stellite, Teflon

- Interior polishes and cleanup

- Special seal materials as graphite, food grade PFTE

- Special vane designs available

- Flexible tips of Teflon or polyurethane

- Painted or coated per customers specification

Specifications

30° Symmetrical

| Size | OAH (in.) | Material of Construction | Actuator Options | Standard Design Temp. | Standard Design Pressure |

|---|---|---|---|---|---|

| 4 | 12.38 | Carbon Steel^ Stainless Steel^ Aluminum^ Hastelloy^ Titanium^ |

Pneumatic Electric Manual | 250°F | 2 PSIG |

| 5 | 14.31 | ||||

| 6 | 16 | ||||

| 8 | 18.75 | ||||

| 10 | 22.38 | ||||

| 12 | 25.12 | ||||

| 14 | 26 | ||||

| 16 | 30 |

45° Symmetrical

| Size | OAH (in.) | Material of Construction | Actuator Options | Standard Design Temp. | Standard Design Pressure |

|---|---|---|---|---|---|

| 4 | 11.06 | Carbon Steel^ Stainless Steel^ Aluminum* Hastelloy^ Titanium^ |

Pneumatic Electric Manual | 250°F | 2 PSIG |

| 5 | 13 | ||||

| 6 | 14.44 | ||||

| 8 | 16.75 | ||||

| 10 | 19.31 | ||||

| 12 | 22.62 |

30° Asymmetrical

| Size | OAH (in.) | Material of Construction | Actuator Options | Standard Design Temp. | Standard Design Pressure |

|---|---|---|---|---|---|

| 3 | 17 | Carbon Steel^ Stainless Steel^ Aluminum^ Hastelloy^ Titanium^ |

Pneumatic Electric Manual | 250°F | 2 PSIG |

| 4 | 19 | ||||

| 5 | 20.5 | ||||

| 6 | 22.25 | ||||

| 8 | 26.5 | ||||

| 10 | 31 | ||||

| 12 | 26.25 |

^Fabricated Only

Customization

Whether you require high-pressure capabilities, special materials of construction, or specific coatings, we can configure your valve to meet your exact requirements. Don't settle for a one-size-fits-all solution - let us build the perfect valve for your process.