Cyclone Separators

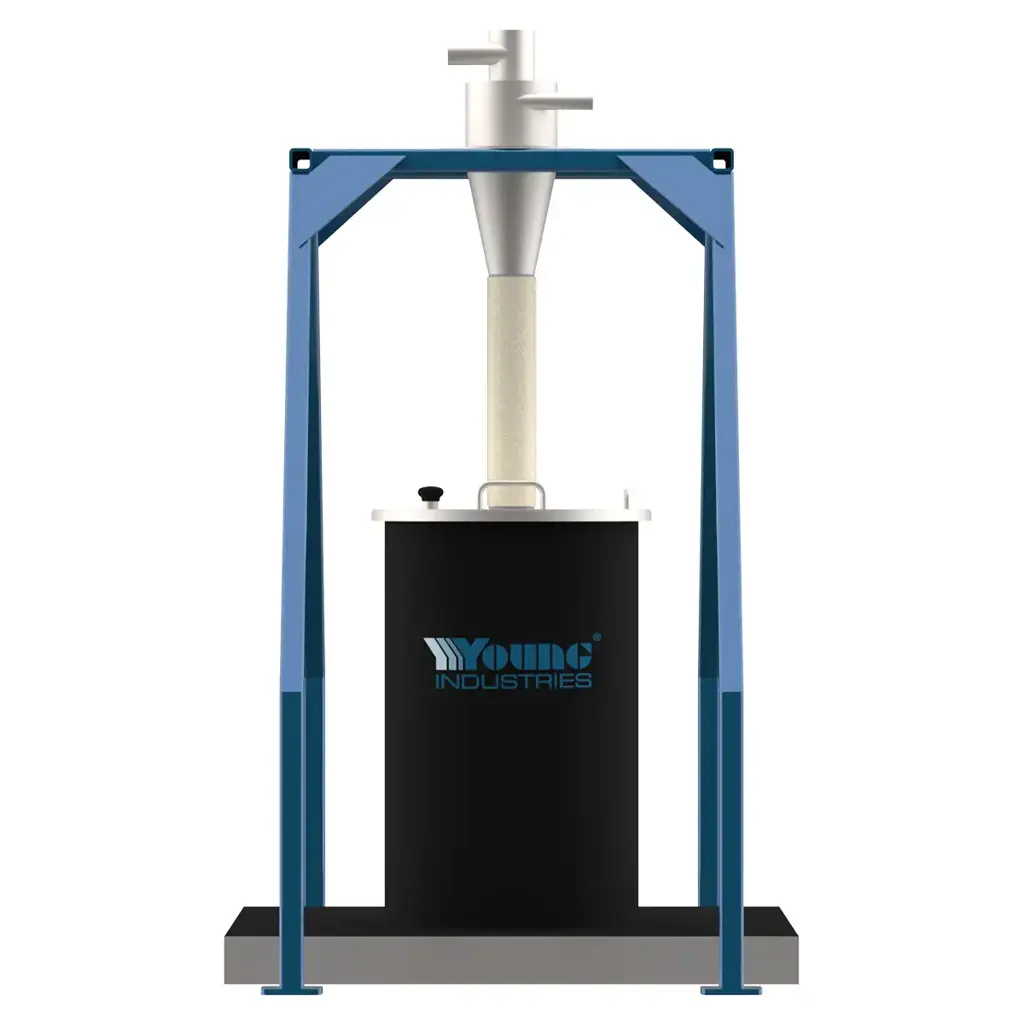

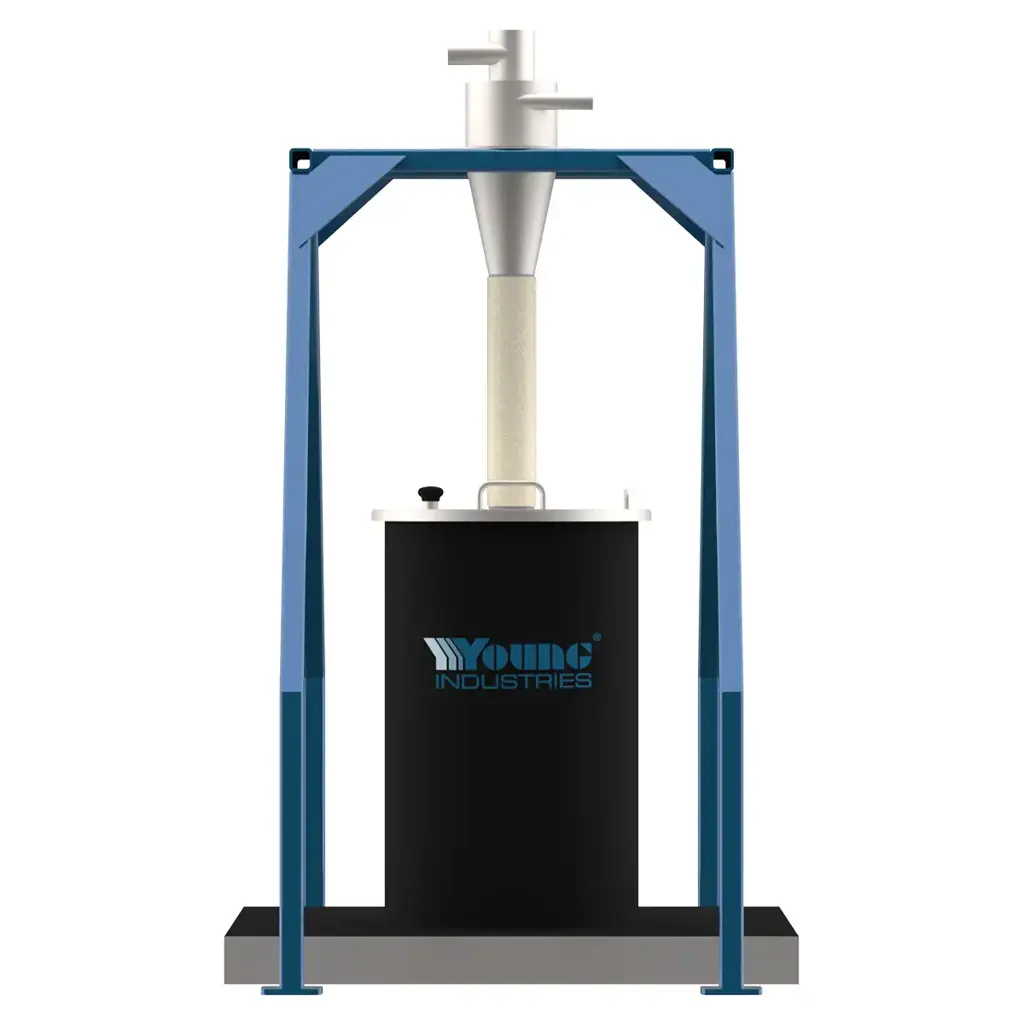

Model D & Model P

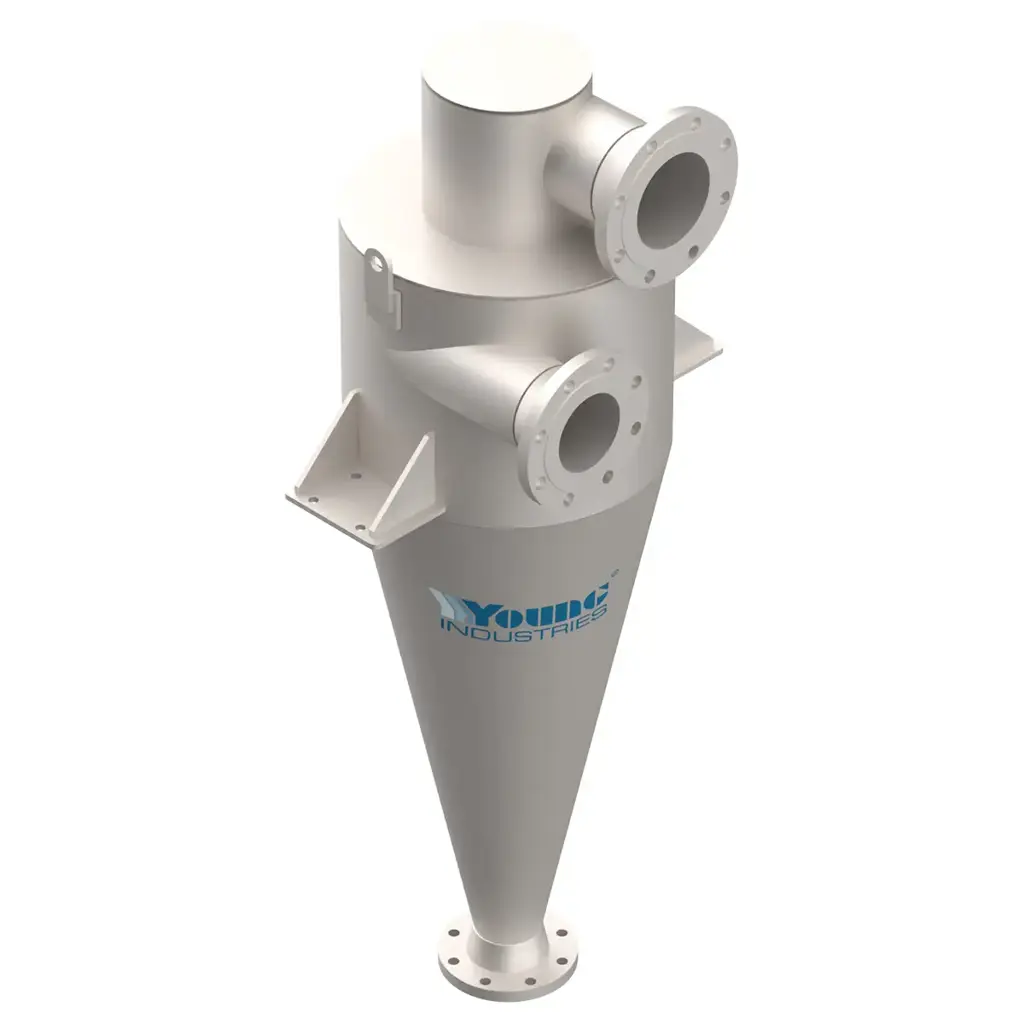

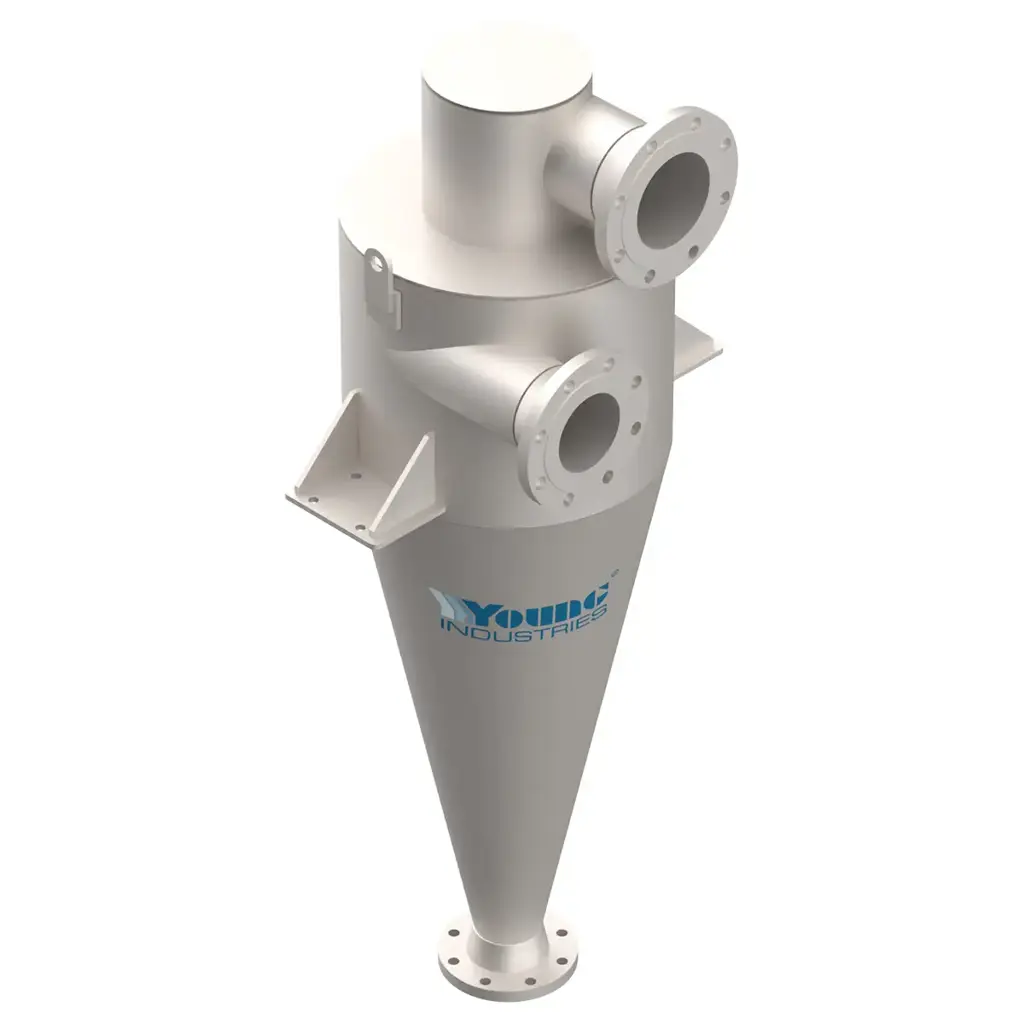

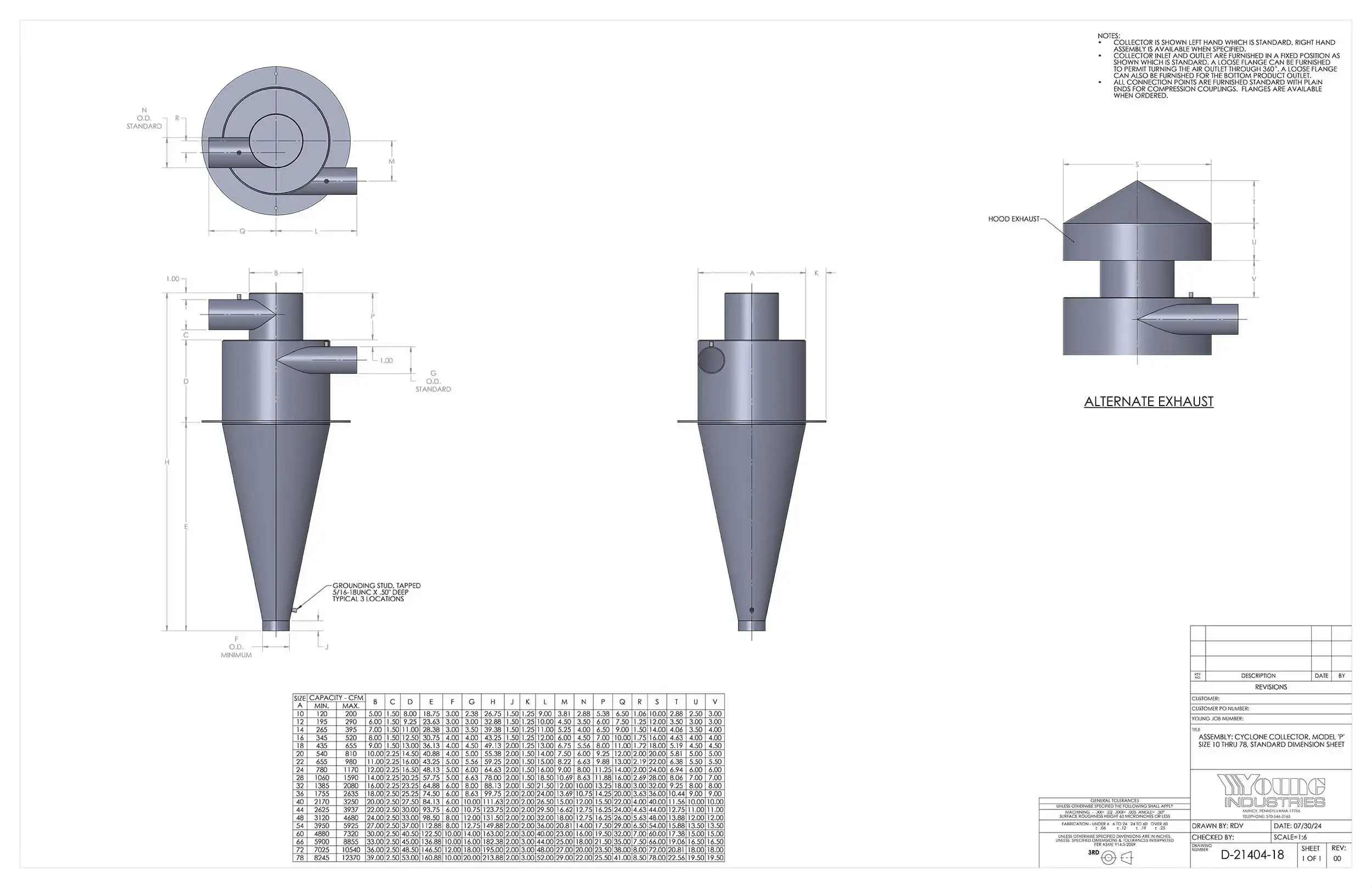

Young Industries Cyclone Separators are a cost-effective means to separate pneumatically conveyed materials from the air stream. Material separation is accomplished within the cyclone by centrifugal force. Product laden air being conveyed by positive or negative pneumatic conveying system enters the collector tangentially near the top of the cylindrical section and moves in a descending spiral. As it enters the conical section, velocities increase, and product is thrown by centrifugal force to interior surface of the cone. The conveying air finds the path of least resistance, which is a centered inner tube within the cyclone, and exits out the top of the collector.

Features & Options

Model P cyclones are designed for large granular and pelletized products, while Model D cyclones handle smaller granular materials, both offering air volumes between 120 and 12,000 CFM and constructed from materials like carbon steel or stainless steel. Both models feature tangential air inlets/outlets, cylindrical bodies, and tapered cone sections, with the ability to integrate with filter receivers for clean air exhaust.

- Plain end pipe connections provided on the air/product inlet, air exhaust, and product outlet

- Constructed from carbon steel or 300 series stainless steel

- High grind interior finish of welds to optimize performance

- Units are available to handle air volumes from 100 CFM to 12,000 CFM

- Flanges can be provided on the air/product inlet, air exhaust, and product outlet

- Discharge hoods can be provided over a center tube exhaust

- The center tube can be connected to the top of the cyclone flanged or with a loose, lap-type flange connection

- Cyclones for high temperature or high pressure can be provided. Units can also be designed and built per ASME Code

- Filters for on the cyclone exhaust for either a positive pressure or negative pressure system arrangement can be provided

- Receiving bins for under the cyclone can be provided. Rotary Valves to service as airlocks can be offered for on the product discharge of the cyclones

- Other materials of construction as needed can be provided. Special paint colors can be provided on the exterior of carbon steel units

Specifications

| Model | Size | Capacity - CFM MIN. |

Capacity - CFM MAX. |

Overall Height (in.) | Material of Construction |

|---|---|---|---|---|---|

| P | 10 | 120 | 200 | 32.125 | CARBON STEEL STAINLESS STEEL |

| 12 | 195 | 290 | 38.88 | ||

| 14 | 265 | 395 | 45.88 | ||

| 16 | 345 | 520 | 50.25 | ||

| 18 | 435 | 655 | 57.13 | ||

| 20 | 540 | 810 | 64.63 | ||

| 22 | 655 | 980 | 69.13 | ||

| 24 | 780 | 1170 | 75.88 | ||

| 28 | 1060 | 1590 | 89.88 | ||

| 32 | 1385 | 2080 | 101.38 | ||

| 36 | 1755 | 2635 | 114 | ||

| 40 | 2170 | 3250 | 127.13 | ||

| 44 | 2625 | 3937 | 140 | ||

| 48 | 3120 | 4680 | 147.75 | ||

| 54 | 3950 | 5925 | 167.38 | ||

| 60 | 4880 | 7320 | 182.50 | ||

| 66 | 5900 | 8855 | 203.88 | ||

| 72 | 7025 | 10540 | 218.5 | ||

| 78 | 8245 | 12370 | 236.38 |

| Model | Size | Capacity - CFM MIN. |

Capacity - CFM MAX. |

Overall Height (in.) | Material of Construction |

|---|---|---|---|---|---|

| D | 10 | 120 | 200 | 33.125 | CARBON STEEL STAINLESS STEEL |

| 12 | 195 | 290 | 40.875 | ||

| 14 | 265 | 395 | 47.875 | ||

| 16 | 345 | 520 | 52.25 | ||

| 18 | 435 | 655 | 59.1875 | ||

| 20 | 540 | 810 | 65.875 | ||

| 22 | 655 | 980 | 70.375 | ||

| 24 | 780 | 1170 | 77.125 | ||

| 28 | 1060 | 1590 | 91.125 | ||

| 32 | 1385 | 2080 | 102.625 | ||

| 36 | 1755 | 2635 | 115 | ||

| 40 | 2170 | 3250 | 128.125 | ||

| 44 | 2625 | 3937 | 141 | ||

| 48 | 3120 | 4680 | 148.75 | ||

| 54 | 3950 | 5925 | 168.375 | ||

| 60 | 4880 | 7320 | 183.50 | ||

| 66 | 5900 | 8855 | 204.875 | ||

| 72 | 7025 | 10540 | 219.50 | ||

| 78 | 8245 | 12370 | 240.375 |

Resources

Customization

Our team of experts will collaborate with you to find the right Cyclone Separator that will meet your needs. Contact us today to discuss your specific requirements.