Simulation

Ensuring Performance Under Pressure

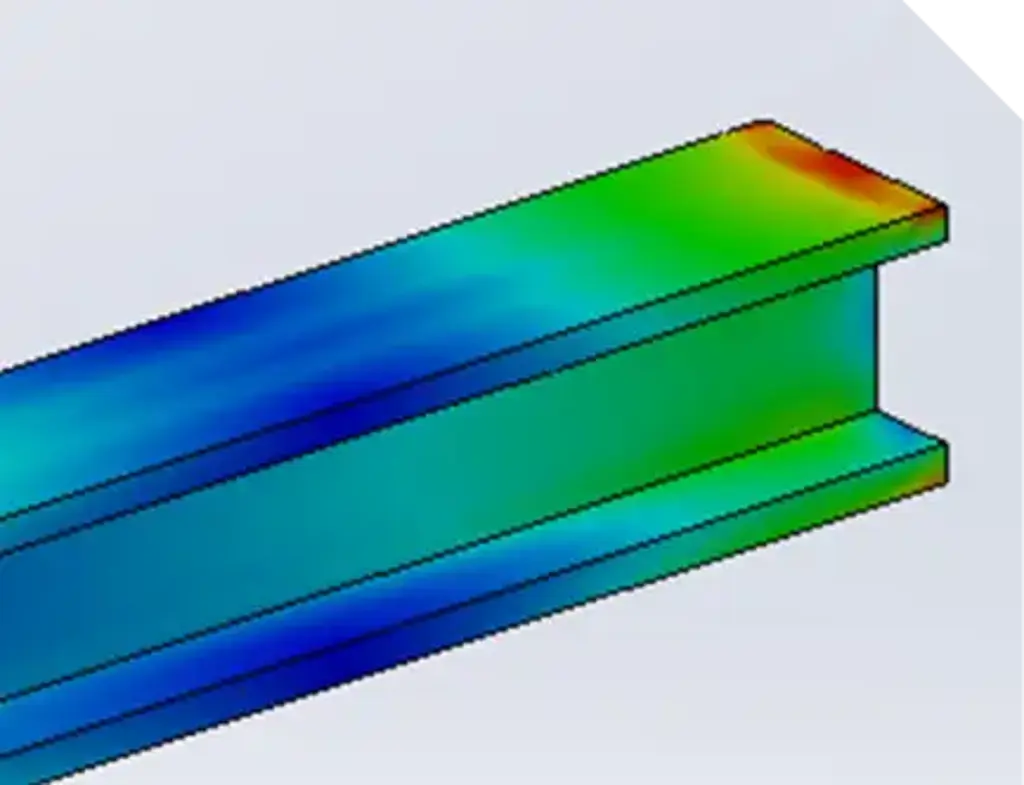

Even the world’s most powerful computer can’t predict the future. But the Young Industries Simulation process comes about as close as you can get. Our team of engineers utilizes SOLIDWORKS Simulation and Finite Element Analysis (FEA) to better understand your equipment’s performance under a wide range of conditions.

Once our analysis is complete, we deliver a comprehensive report that provides clear supporting documentation of all results.

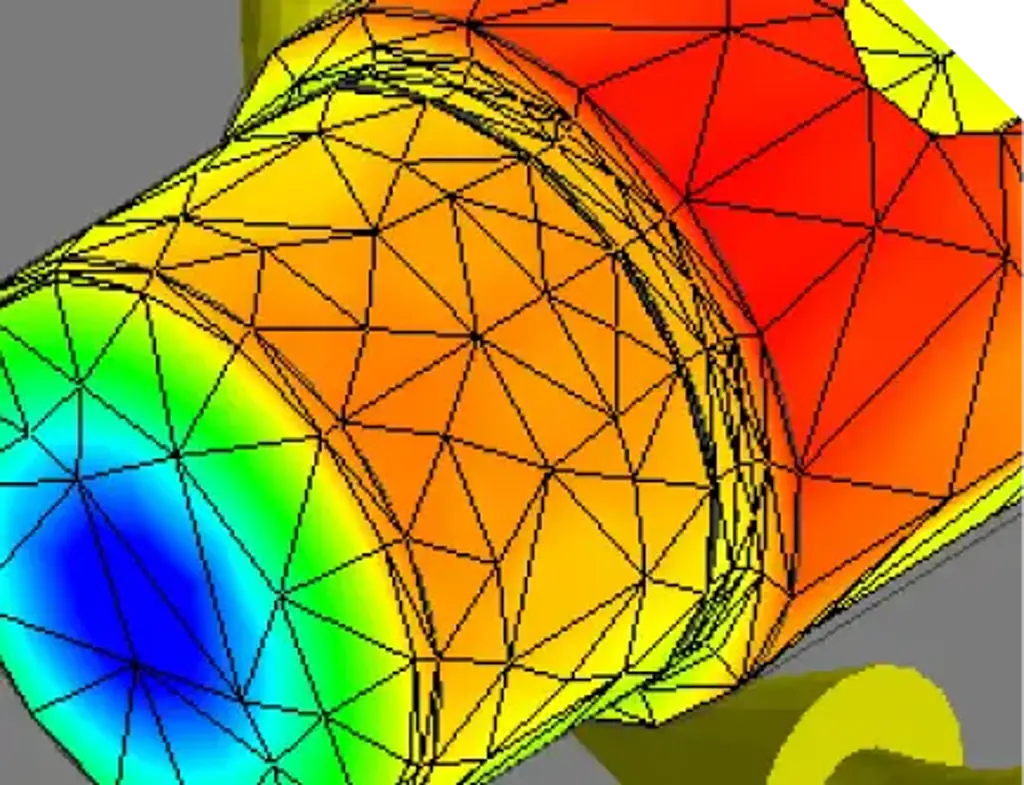

Linear Static Stress Analysis

We establish basic static loading conditions to assess a wide range of operational elements, including strength of rotating shafts, lifting components, equipment supports, internal and external static vessel pressures, foundation loads, and more.

- Bulk Bag Lifting Brackets

- TransFlow Cones and Storage Bins

- Filtration Equipment

- Rotary Valves

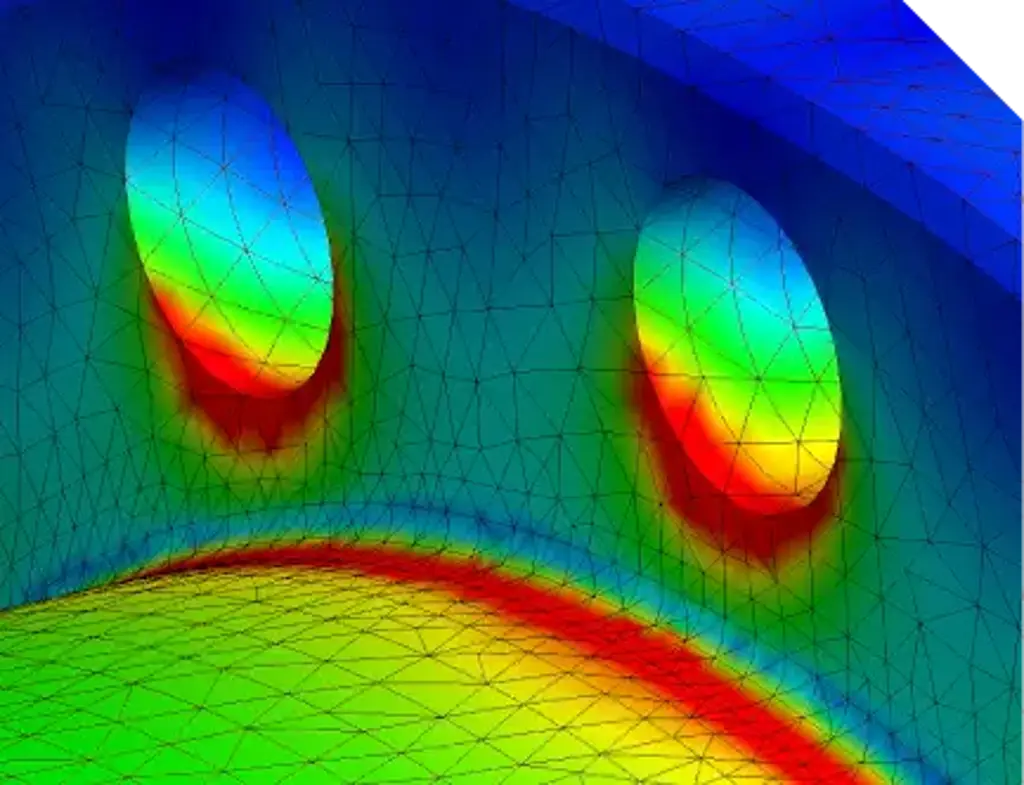

Fatigue Analysis

We apply cyclical loading condition simulations to your equipment to assess strength under pressure and/or thermal cycling.

- ASME Pressure Vessels

- Heating and Cooling Jackets for Rotary Valves

- Horizontal Mixers

- Twin Shaft Mixers

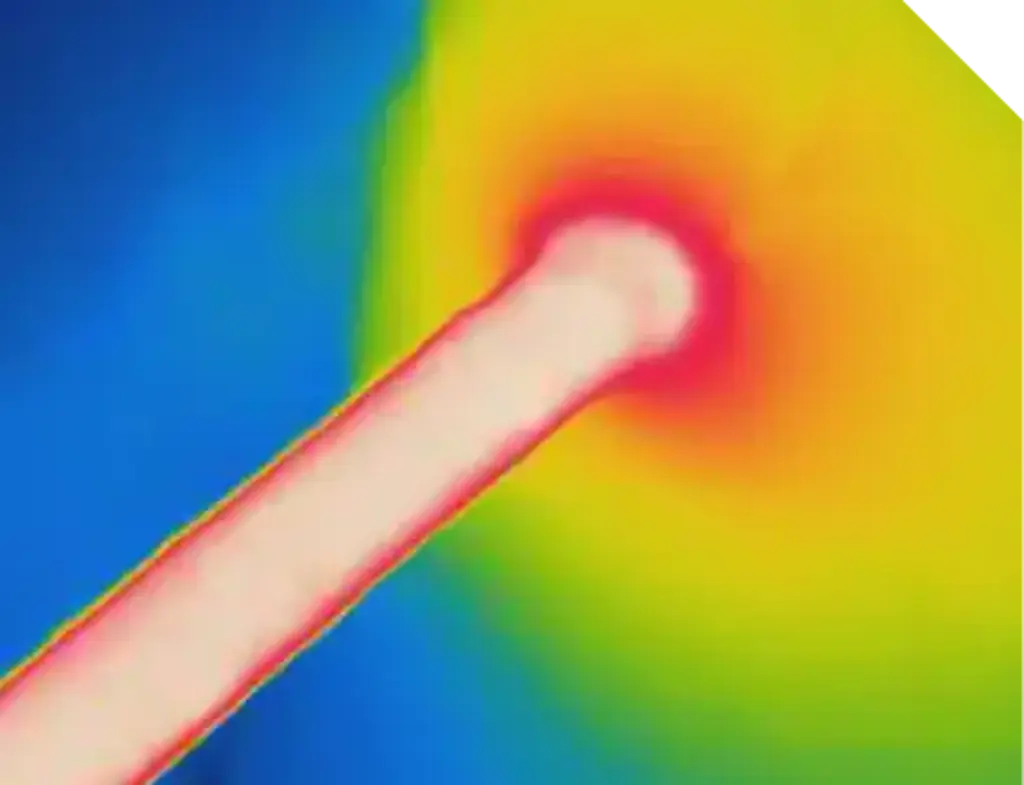

Thermal Analysis

We leverage transient thermal analysis (heat transfer) to analyze thermal growth and temperatures at specific equipment locations. This is especially critical for assessing bearing and seal thermal exposure on all rotating equipment with elevated design temperature ratings.

- Heating and Cooling Jackets

- Rotary Valves

- Horizontal Mixers

- Twin Shaft Mixers

- Model B and Model C Diverter Valves

Buckling Analysis

We utilize this test to analyze the performance of load bearing structures under compressive forces in your operation.

- Bulk Bag Unloading Frames

- Custom Frames for supporting equipment

Benefits

Safer Testing Conditions

Allows for the safe simulation of conditions that may be dangerous or difficult to replicate in a physical test environment.

Detailed Results

Offers more detailed and accurate results over other methods, ensuring the safety and efficiency of each product.

Efficient

Saves time vs. doing the analysis by hand or inflicting the conditions to test the product in person.

Versatile

Can be used for an endless number of products once you’ve invested in the software.

Cost-effective

Helps your business keep its overhead costs down and create products of the highest quality.