Micro High Capacity

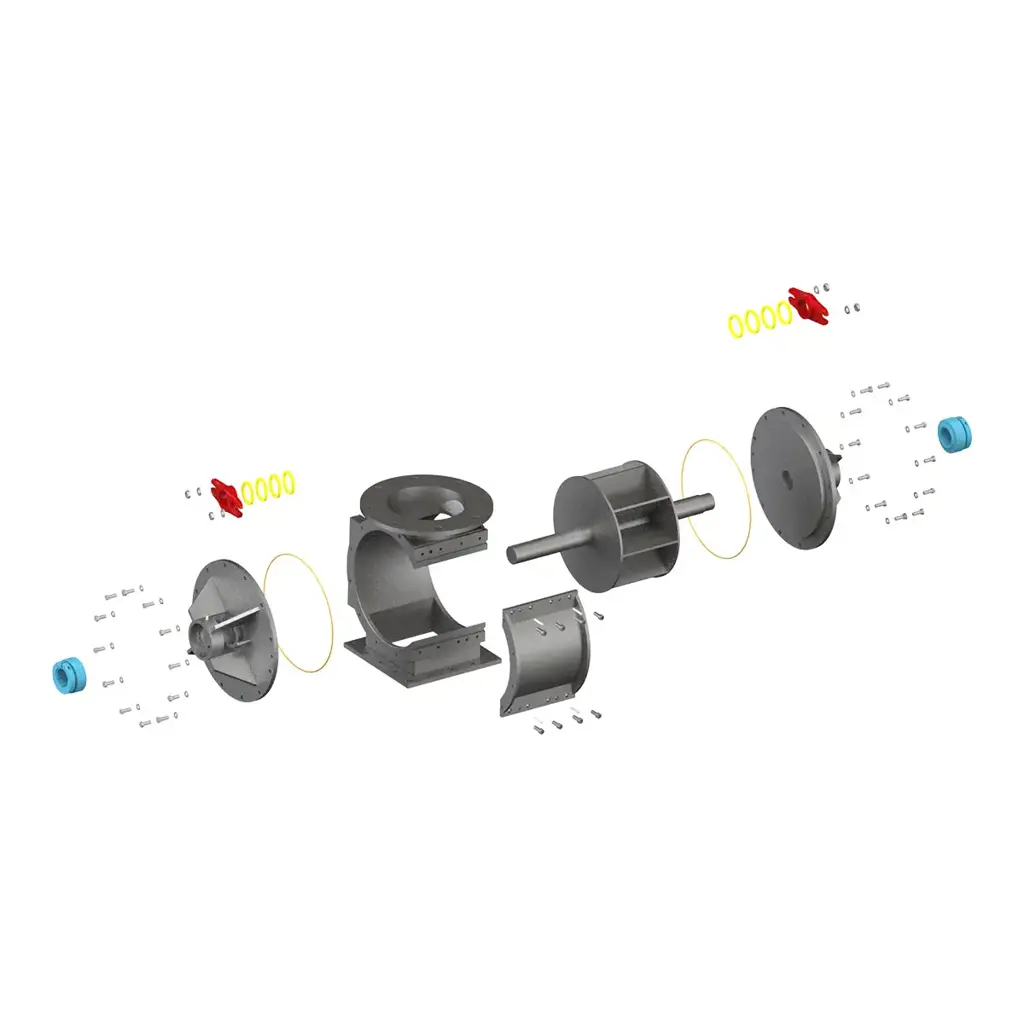

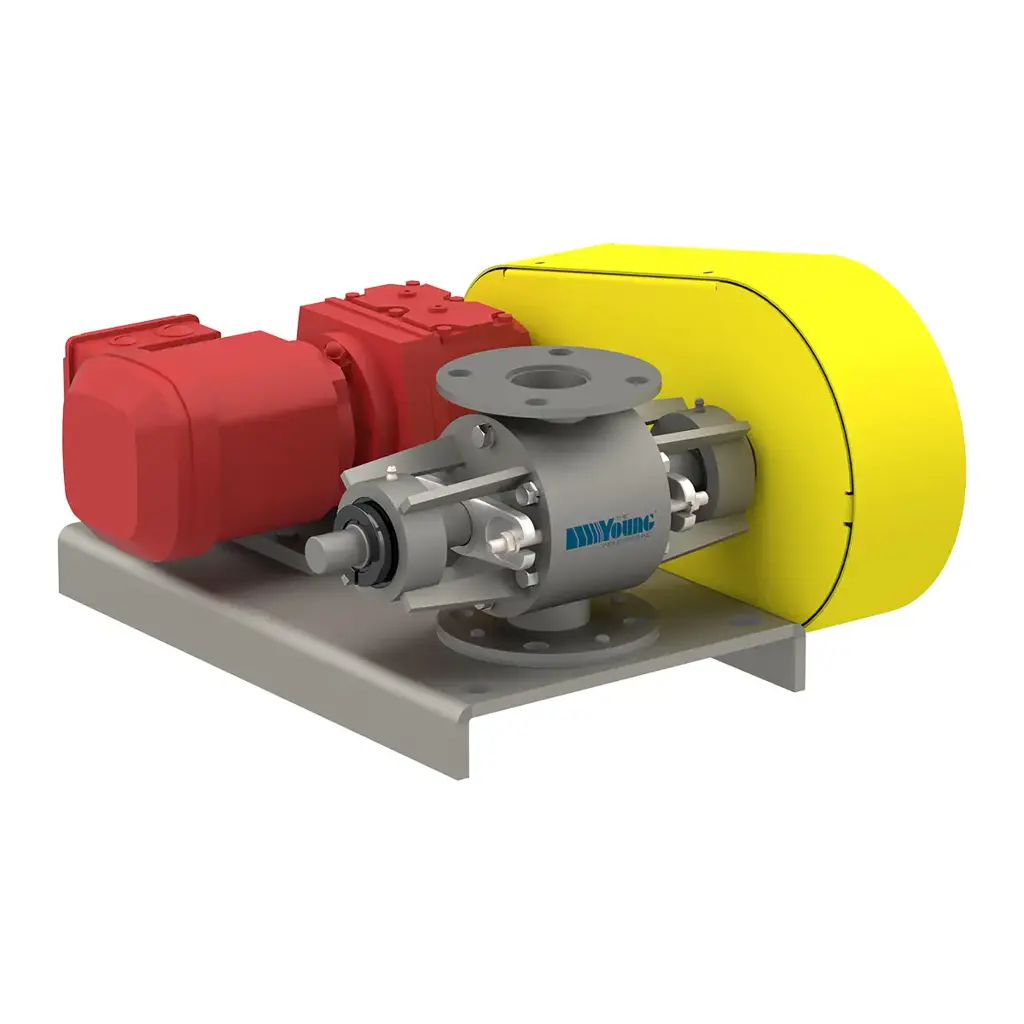

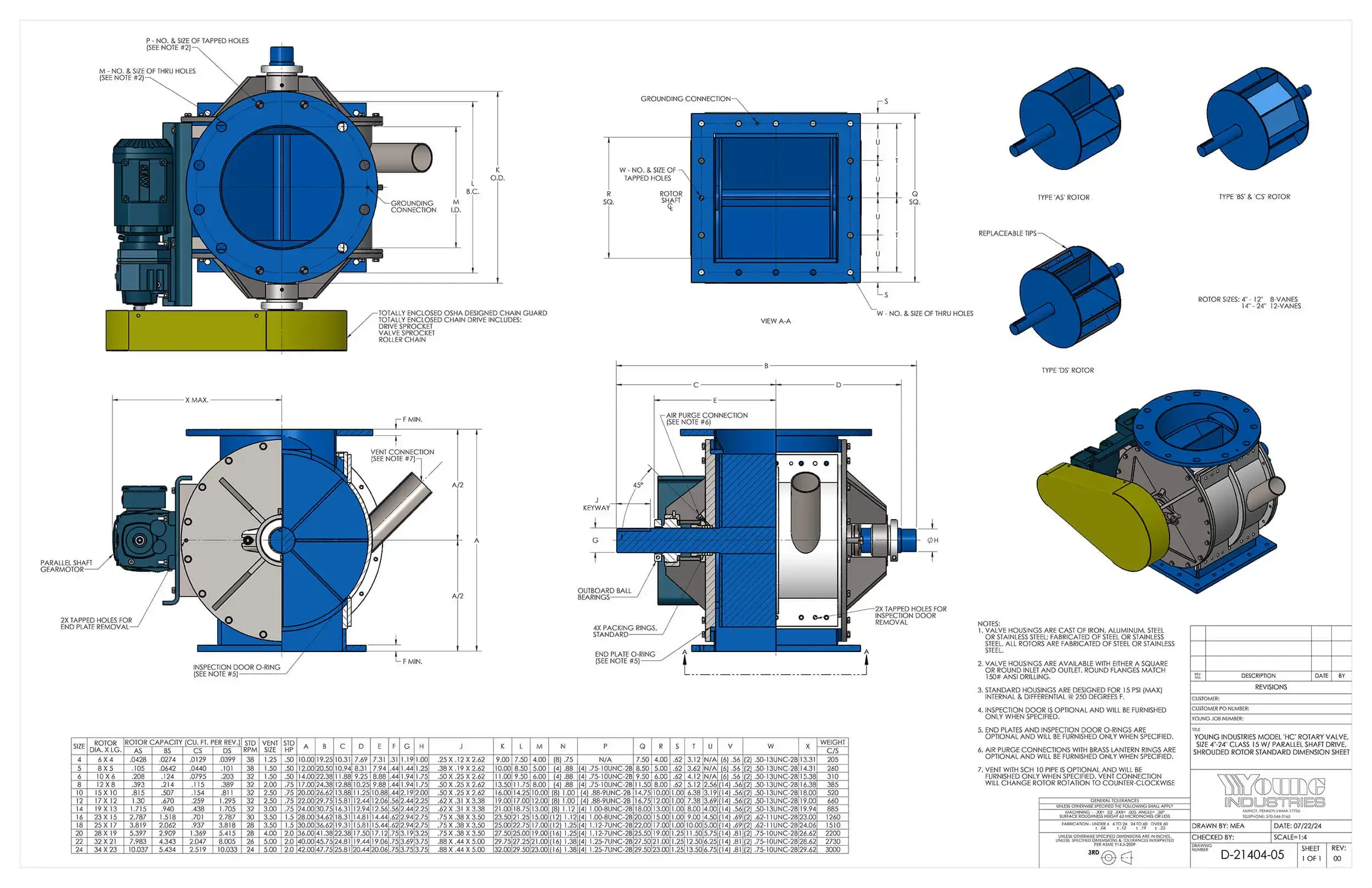

Micro-Model HC Drop-Thru Rotary Valves, perfect for your low-capacity or laboratory needs. These valves pack the same performance and reliability as our larger models, with outboard mounted bearings and a durable packing gland shaft seal. Available in sizes 1" through 3" with round or square flanges.

Here's what makes them stand out:

- Reliable Sealing: Vertical inlet and discharge throats with a two-blade seal and precision-machined housing ensure minimal air or gas leakage

- Built Tough: 15 PSIG housing and differential pressure or vacuum rating

- Adaptable Design: Fabricated or cast designs available in carbon steel, stainless steel, or aluminum

- High-Temp Performance: Standard operating temperature up to 250°F, with designs available for up to 1600°F

- Smooth Operation: Outboard-mounted precision ball bearings and heavy-duty rotor shafts for stability

- Multiple Configurations: Two basic rotor styles, each with four different types of rotors, including standard, partially filled, and adjustable lips

- Easy Installation: Round or square inlet and discharge flanges for easy integration

- Safety and Compliance: Grounding and bonding connection to NFPA specifications

- Complete Package: Includes a right-angle gearmotor, drive chain, and safety guard

Customization Options:

- High-Pressure Designs: Up to 350 PSIG

- High-Temperature Designs: Up to 1000°F

- Special Sizes: 1" to 3" and 28" to 36"

- Drive Options: TEFC or explosion-proof motors, direct-connected drives

- Material Choices: 316 stainless steel, Hastelloy, or titanium

- Interior Coatings: Chrome plating, nickel plating, tungsten carbide, Stellite, Teflon for abrasion resistance and material release

- Packing Materials: Graphite, food-grade PTFE