INTRO: Filter-Bag Dump Stations & Bag Compactors

GUIDE: Filter-Bag Dump Stations - Filter Removal

Filtered

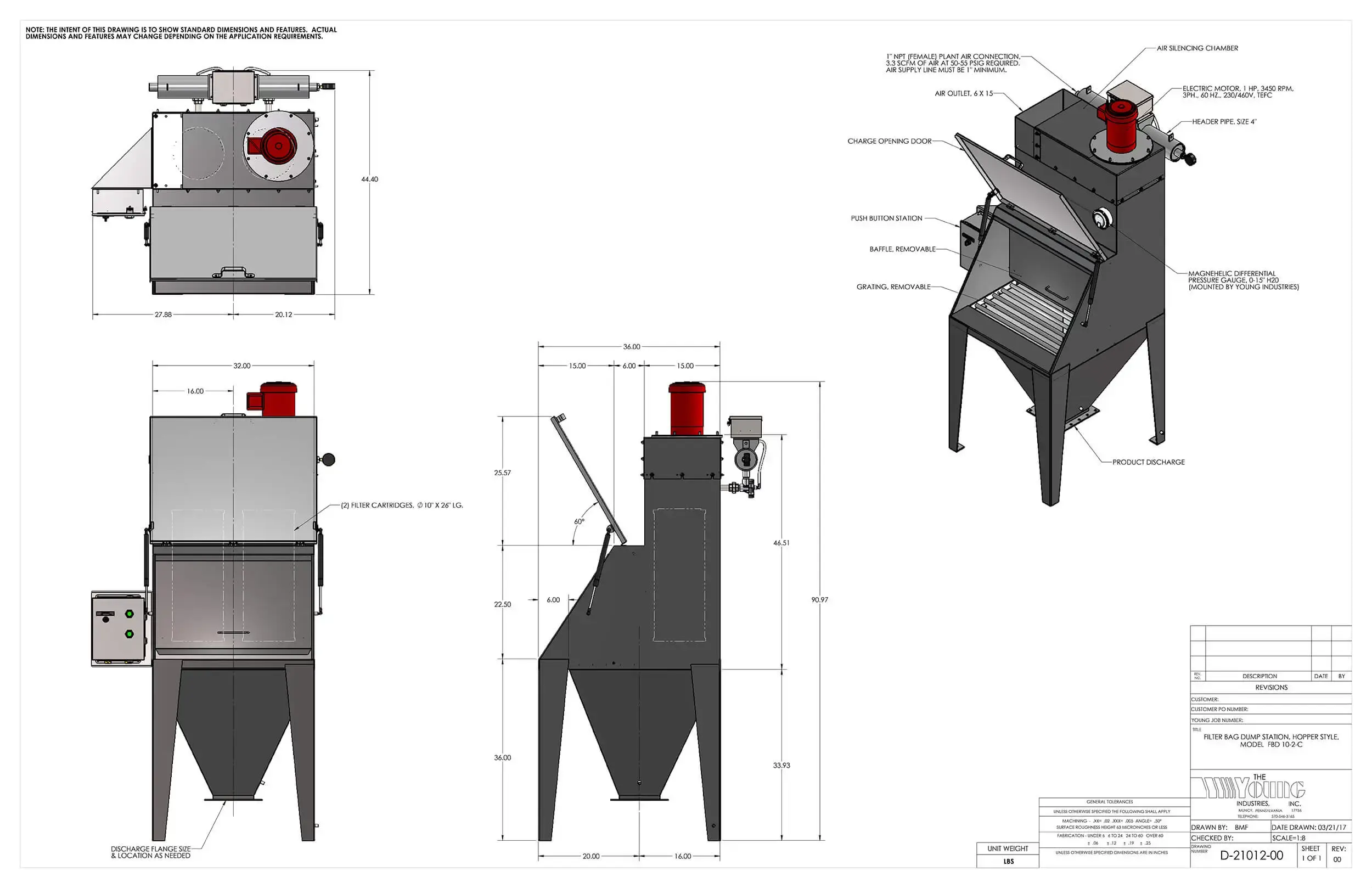

Young Industries Filter Bag Dump Stations each have an integral fan which draws dust generated from the bag dumping operation to the filter media located on the back interior of the stations. The dust is then pulsed using plant compressed air from the filter media and falls back into the hopper below. This technology results in no loss of product to a central dust collection.

Features & Options

Young Industries offers multiple standard size stations to cover a wide range of applications for dumping bulk bags, paper bags or drums. With the range of units offered the user can determine what size station best meets their needs based on the physical size of the bags or drums being dumped in combination with the number of bags or drums per batch.

- 6” – 12” Square or Round Discharge Connection

- Construction of Carbon Steel, 304 S/S or 316 S/S

- Self-contained dust collection for no loss of product to a central dust collector

- Magnehlic Differential Pressure Gauge to monitor filter health

- Removable bag grate

- Polyester Felt Filter Bags or Filter Cartridges

- Designs for handling both Paper Bags & Bulk Bags

- Charge Door

- Flange Mounted Units

- Pneumatic Bag Compactors

Specifications

| Model | Bag Area Width | Overall Width | Overall Depth | Overall Height | Material of Construction |

|---|---|---|---|---|---|

| 24-6 | 24" | 37.88" | 35.38" | 76" | Carbon Steel Stainless Steel |

| 30-6 | 32" | 46" | 38.21" | 75.72" | |

| 10-2-C | 32" | 38" | 36" | 90.97" | |

| 10-3-C | 38" | 52.25" | 38" | 91.1" | |

| 42-8 | 45" | 59" | 47" | 81.97" | |

| 10-8-C | 54" | 62" | 58" | 100" |