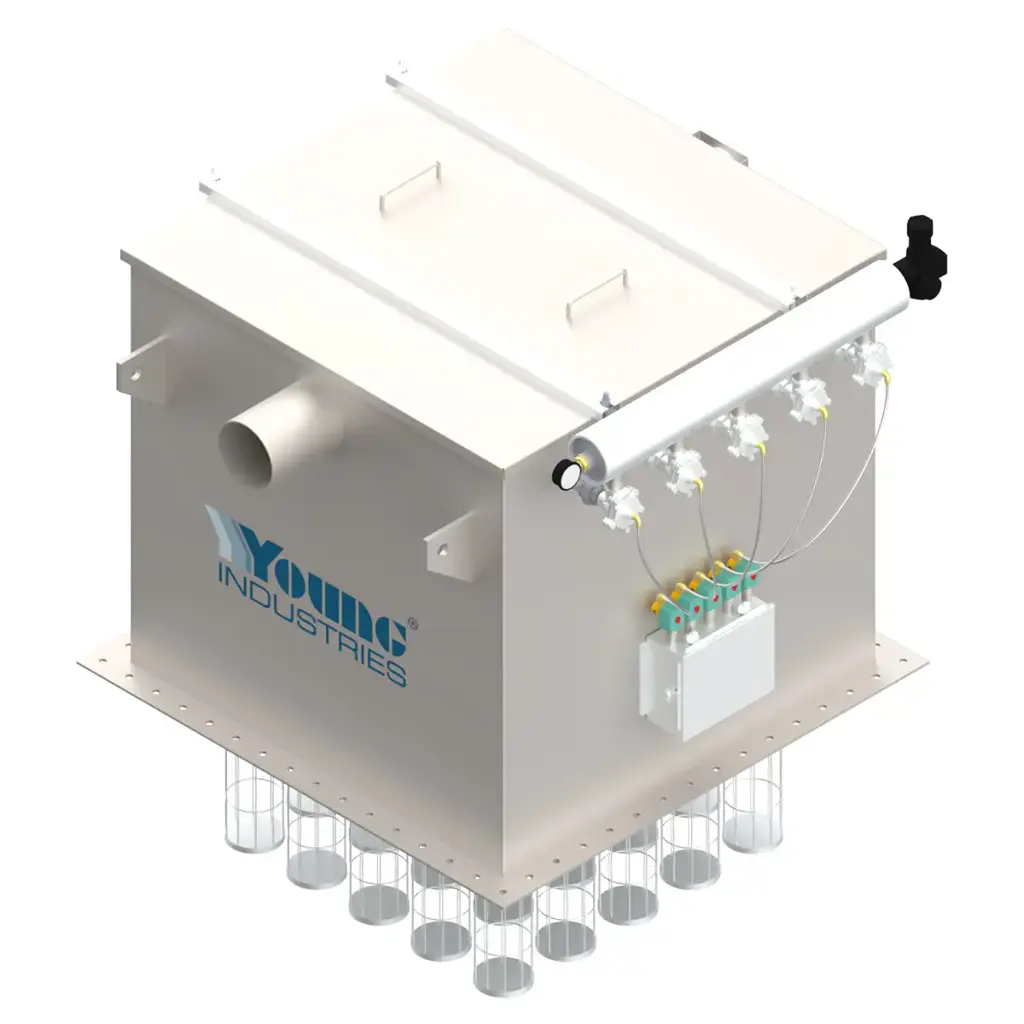

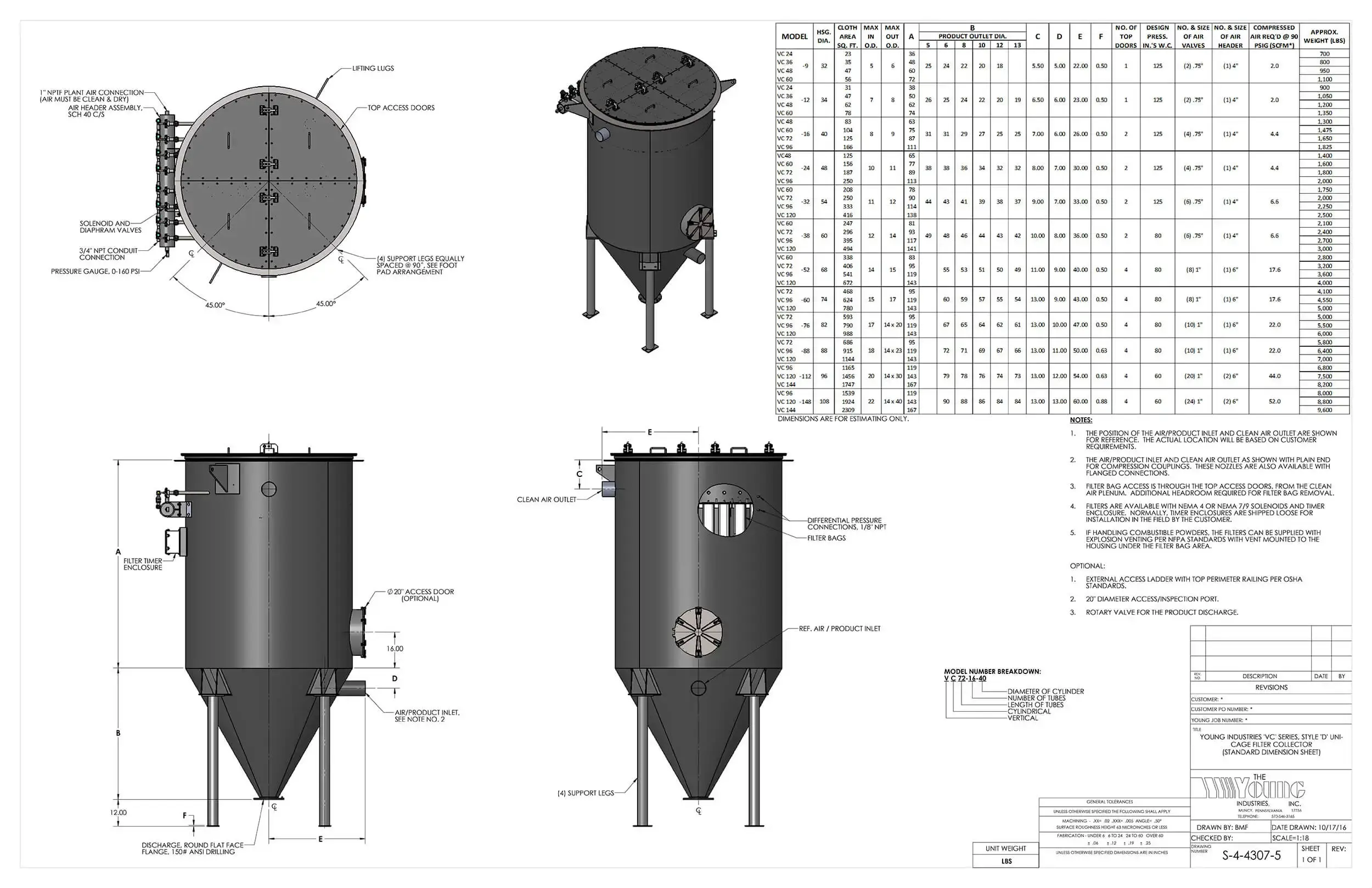

Uni-Cage Bin Vent Filters

Our Uni-Cage Bin Vent Filters combine durability with ease of maintenance, thanks to their unique design that allows top or side access to filter bags. These units are engineered to operate efficiently in high-demand environments, ensuring clean air and minimal downtime.