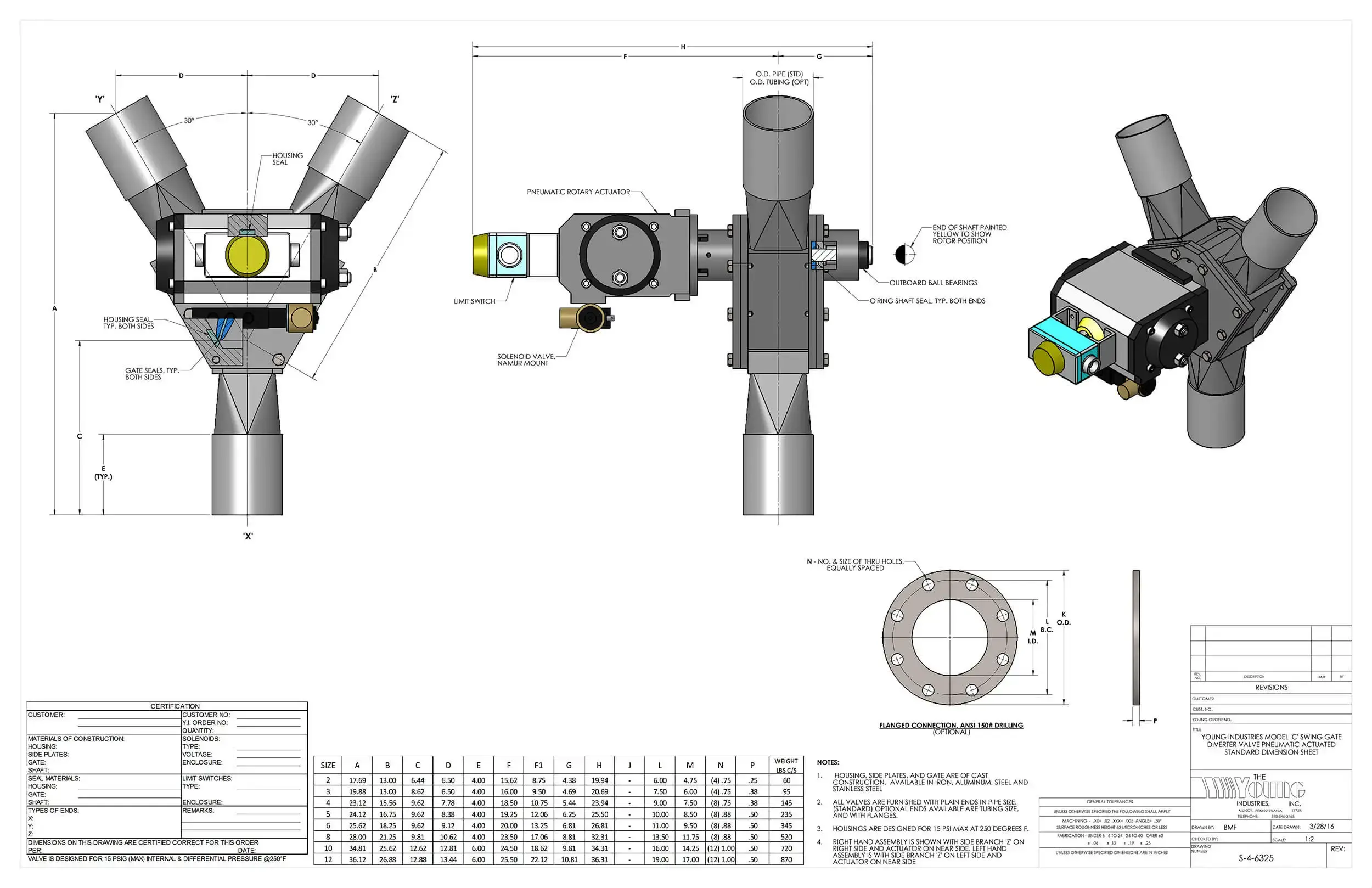

Sym. Swing Gate

Model C Diverter

The Symmetrical Swing Gate Diverter Valve is widely used in both positive and negative pneumatic conveyor systems. All sealing surfaces are precision-machined, and the heavy-duty cast swing gate includes Teflon and neoprene sealing strips for a tight, reliable seal. Proven to provide superior performance in bulk materials handling, the Model C valve offers both reliability and low cost of ownership.

Features & Options

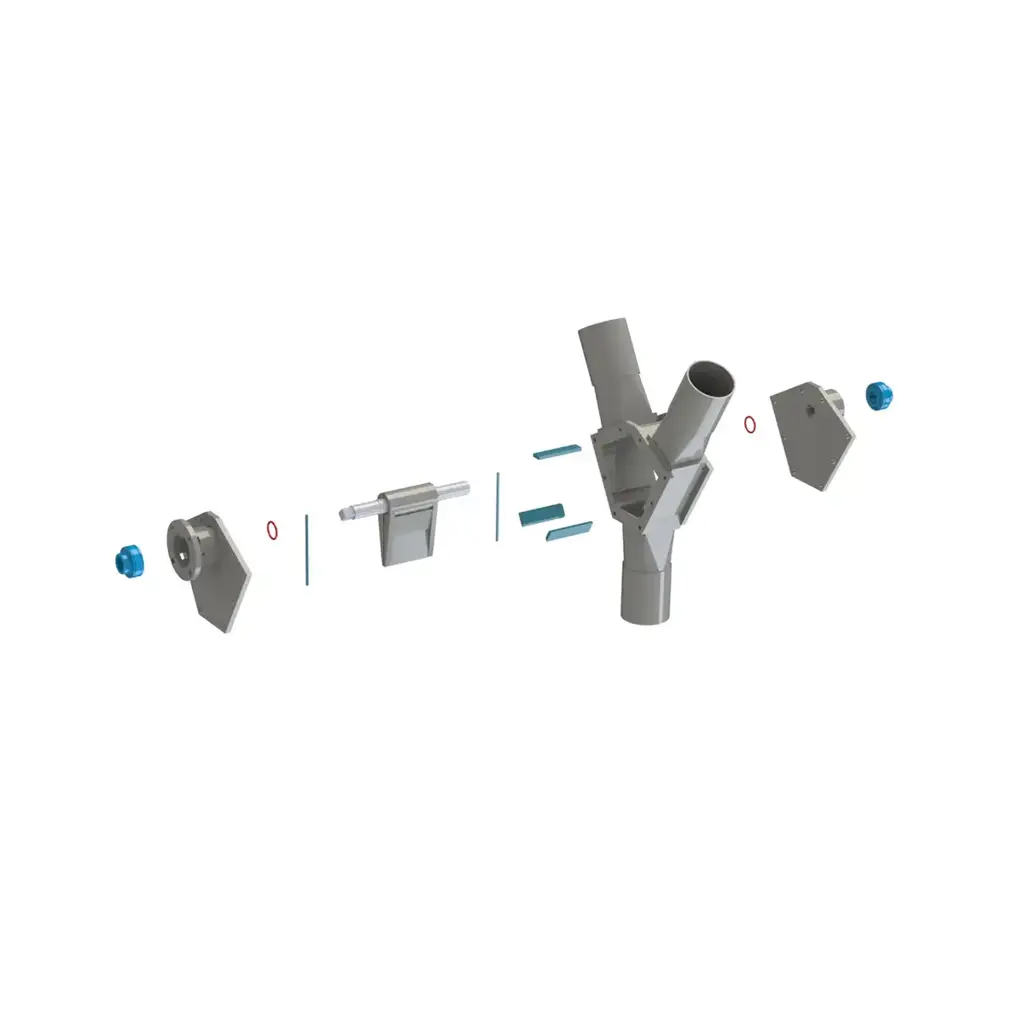

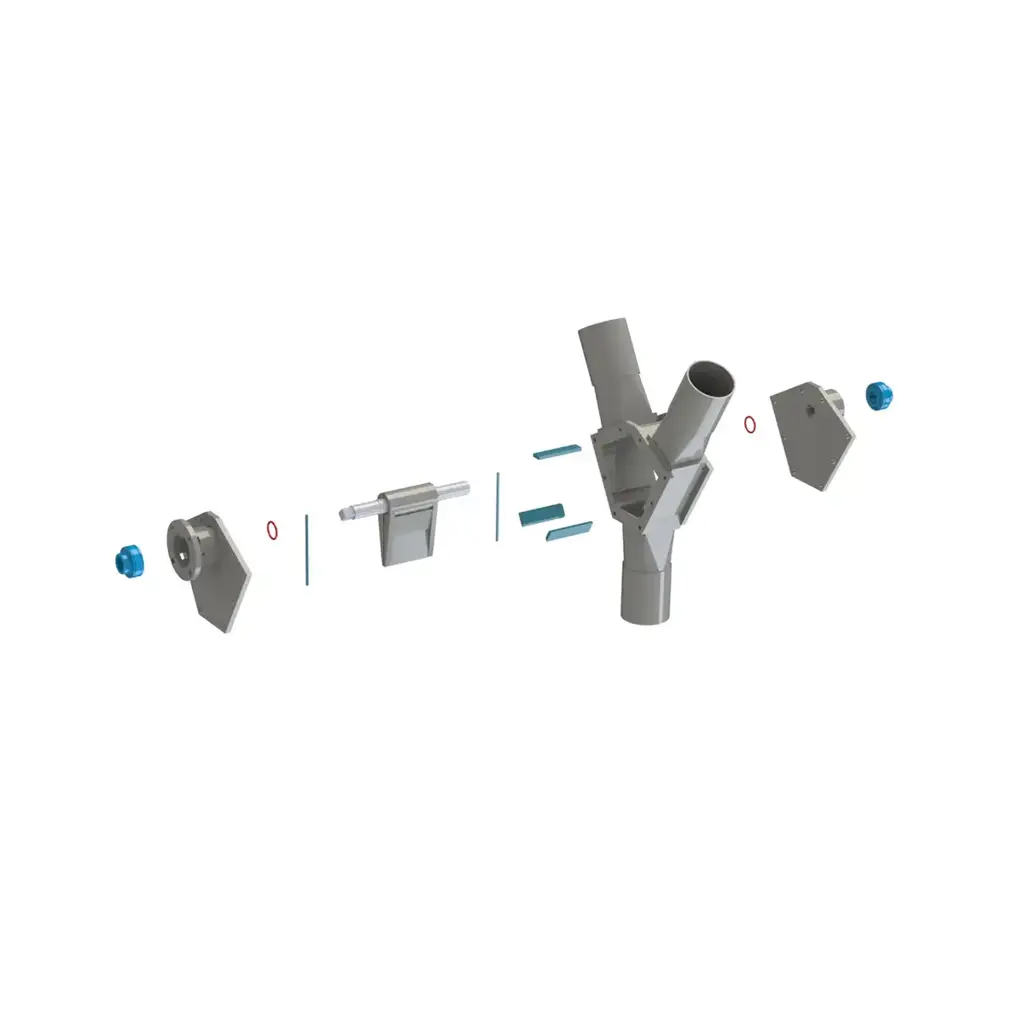

Model C Swing Gate Diverter Valve provide the lowest leakage in the industry. The gate shaft is supported by ball bearings for proper alignment, with the actuator directly coupled to the shaft to distribute torque evenly, reducing stress on components. Access to the valve is simple via removable side plates, allowing for maintenance without removing the valve from the system, minimizing downtime and production loss.

- Used in both positive pressure and vacuum pressure pneumatic conveyors

- Operates at internal and external pressures up to 15 PSIG

- Mounts in any position without loss of efficiency

- Designed with each diversion leg offset 30° from the inlet leg

- Standard size range is 2″ through 12″

- Furnished standard in pipe sizes with plain ends for compression couplings

- Disassembles without removal from the convey line

- Made of cast steel and cast stainless steel

- Raw materials are traceable to standard specifications with ASTM the most used specification

- Up to 250°F operation temperature

- Neoprene O seals at gate shaft

- White neoprene sealing strips at the hub and tips areas of the gate

- Grounding and bonding connection to NFPA specifications

- Painted blue enamel epoxy

- Completely assembled and tested

- Tubing or pipe ends available

- Flanged end connections available

- High pressure designs

- High temperature design to 400°F

- Special sizes available

- Special materials available, including 316 Stainless steel and Hastelloy

- Interior coating to provide abrasive resistance to chrome plating, nickel plating, tungsten carbide, Stellite, Teflon

- Interior polishes and cleanup

- Special sealing materials as graphite, food grade PTFE

- Rotary pneumatic operator, with NEMA 4 single solenoid valves, single-pole double-throw and 2 limit switches – one indicating for each leg.

- Electric operator, with 2 limit switches – one switch for each leg.

- Manual operator

- Painted or coated per customers specification

Specifications

| Size | OAH | Material of Construction | Actuator Options | Standard Design Temp. | Standard Design Pressure |

|---|---|---|---|---|---|

| 2 | 17.69 | Carbon Steel* Stainless Steel* Aluminum* Hastelloy^ Titanium^ |

Pneumatic Electric Manual | 250°F | 15 PSIG |

| 3 | 19.88 | ||||

| 4 | 23.12 | ||||

| 5 | 24.12 | ||||

| 6 | 25.62 | ||||

| 8 | 28 | ||||

| 10 | 34.81 | ||||

| 1236.12 |

*Cast or Fabricated

^Fabricated Only

Customization

We partner with you to understand your challenges and design custom modifications that ensure seamless integration and optimal performance. Whether you need unique dimensions, specialized materials, or specific coatings, we have the expertise to deliver a valve that's truly tailored to your process.