Rotary Plug

Model TU Diverter

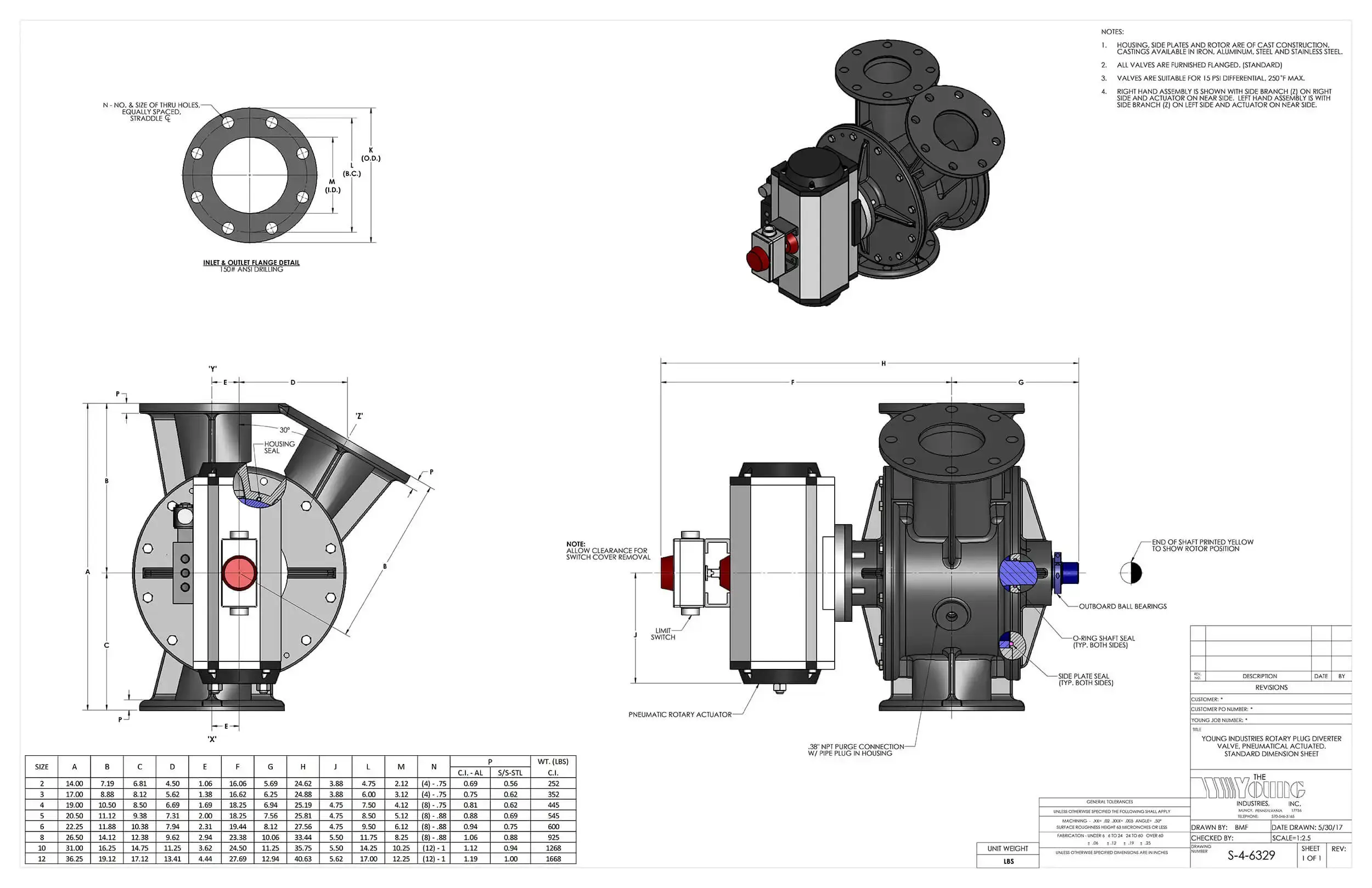

Young Industries' Rotary Plug Diverter Valves reliably direct bulk materials in pneumatic conveying or gravity flow systems. They prevent cross-contamination and minimize leakage for smooth, efficient operation.

Built with heavy-duty cast materials, these versatile valves provide a tight seal and long service life. A single valve can route material from one line to two, from two lines to one, or connect in series for complex routing.

Features & Options

The Rotary Plug Diverter Valve features precision-machined sealing surfaces, O-ring seals, and a closed rotor design. These valves provide a nearly leak-proof barrier between the atmosphere and diversion legs. The offset design of the diversion legs allows for efficient material routing with minimal product hang-up.

The direct-coupled actuator minimizes stress on components, while removable end plates simplify maintenance and reduce downtime.

- Designed to operate at internal and external pressures up to 15 PSIG

- Mounts in any position without loss of efficiency

- Designed with one diversion leg offset 30° from the straight through leg

- Standard size range is 2″ through 12″

- Furnished standard in pipe sizes with flange ends having 150# drilling

- High pressure designs available

- High temperature design to 400°F

- Special sizes available

- Special materials available include 316 stainless steel and Hastelloy

- Interior coating to provide abrasive resistance including chrome plating, nickel plating, tungsten carbide, and Stellite

- Interior polishes and cleanup

- Special sealing materials as graphite, food grade PTFE

- Rotary pneumatic operator, with NEMA 4 single solenoid valves, single-pole double-throw and 2 limit switches – one indicating for each leg

- Electric operator, with 2limit switches – one switch for each leg

- Manual operator

- Painted or coated per customers specification

Specifications

| Size | OAH | Material of Construction | Actuator Options | Standard Design Temp. | Standard Design Pressure |

|---|---|---|---|---|---|

| 2 | 14 | Carbon Steel* Stainless Steel* Aluminum* Hastelloy^ Titanium^ |

Pneumatic Electric Manual | 250°F | 15 PSIG |

| 3 | 17 | ||||

| 4 | 19 | ||||

| 5 | 20.5 | ||||

| 6 | 22.25 | ||||

| 8 | 26.5 | ||||

| 10 | 31 | ||||

| 12 | 36.25 |

*Cast or Fabricated

^Fabricated Only

Resources

Customization

We understand that every pneumatic conveying system is unique. That's why we offer extensive customization options for the Model TU Diverter Valve. From special materials of construction and high-temperature designs to a variety of drive options and coatings, we'll configure your valve to meet your exact needs. Our team of experts will work with you to ensure your Rotary Plug Valve delivers optimal performance and seamlessly integrates into your operation.