INTRO: TransFlow® Technology

DEMO: TransFlow® Test Hopper

TEST: Iron Oxide with TransFlow®

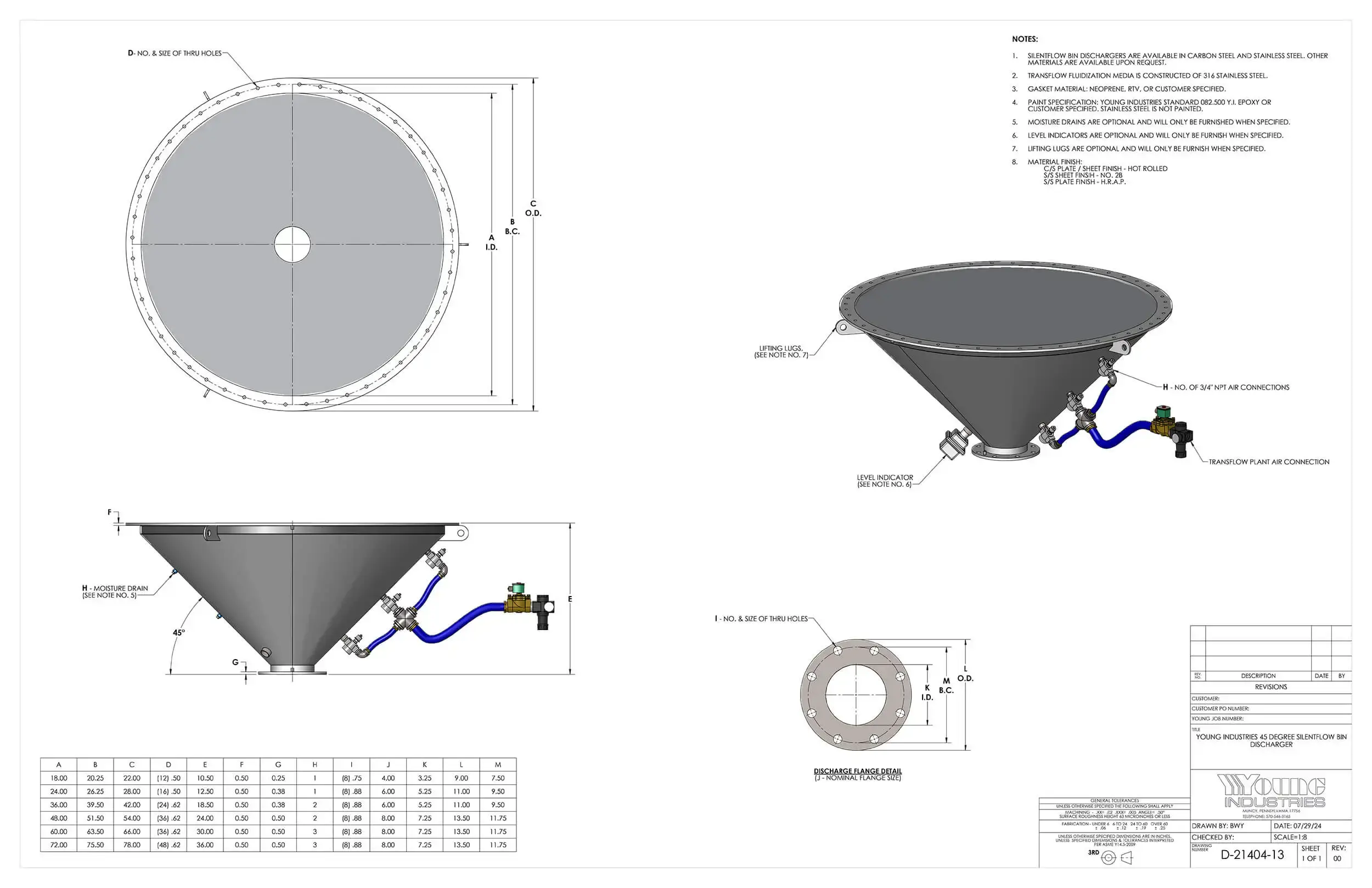

Discharge Bins

Say goodbye to bridging, rat-holing, and inconsistent flow. SilentFlow Bin Dischargers streamline even the toughest powder handling applications with our patented TransFlow® fluidization media. TransFlow® gently aerates stored material, making stubborn cohesive powders flow like liquids for reliable, worry-free discharge.

Features & Options

SilentFlow Bin Dischargers aren't just built to last – they're designed to elevate your entire material handling process. From the robust construction to the intelligently engineered features, SilentFlow delivers dependable performance on even the most challenging powders.

SilentFlow Dischargers can be easily dropped in to replace your existing vibratory bin bottoms, silo cones, or mass flow cones. They also integrate seamlessly into new storage vessels. Whatever your process or material needs, SilentFlow Dischargers are built to serve a wide range of industries, including chemical, petrochemical, food, ceramic, glass, and paint.

- Standard sizes from 18” to 72” diameter with 60° and 45° cone angles.

- Standard materials for construction include carbon steel, 304 S/S, and 316 S/S bins, hoppers, and silos and 316L S/S TransFlow® fluidizing media.

- Operating temperatures up to 250° F are standard, with units capable of operating at temperatures as high as 1,000° F available.

- SilentFlow Bin Dischargers operate on a low-volume, low-pressure, clean, dry compressed air or gas supply.

- Reliable, effective, higher flow rates from hoppers and silos increase production.

- Reduced maintenance costs: no moving parts, no high voltage, no stress cracks from vibrators, reduced downtime from bridges, ratholes, plugged outlets, no flexible connectors, boots, or arms need to be replaced.

- Air or gas piping systems and controls

- Manual on/off ball valves or automatic on/off solenoid valves, including NEMA 4 or NEMA 7/9 Solenoid valves that operate on 24 VDC or 120 VAC

- Lifting lugs, support lugs, level indicators, indicator connections, flow meters, pressure switches and transmitters

- Straight wall cylinder sections, bolted or welded

- Bolt-on or welded covers or roofs

- Bin vent filters for cleaning displaced air, rotary valves and screw feeders for metering the discharge of product

- Manual or automatic butterfly or knife gate valves for stopping the flow of product

- Pneumatic or mechanical systems to fill or convey product to and from the bin, hopper or silo

- Special paint colors on the exterior of carbon steel units

- Compressors for delivering the air supply

- Custom shapes, sizes, cone angles, and materials of construction

Specifications

| Standard Dia. (Inlet) | Standard Dia. (Outlet) | Standard OAH (45°) | Standard OAH (60°) | Material of Construction | Standard Design Pressure | Standard Design Temperature |

|---|---|---|---|---|---|---|

| 18" | 3.25" | 0.5 | 16.00" | Carbon Steel* Stainless Steel* Aluminum* Hastelloy^ Titanium^ |

.63 PSIG Internal/External | 0-120°F |

| 24" | 5.25" | 12.50" | 19.00" | |||

| 36" | 5.25" | 18.50" | 30.00" | |||

| 48" | 7.25" | 24.00" | 38.75" | |||

| 60" | 7.25" | 30.00" | 49.25" | |||

| 72" | 7.25" | 36.00" | 60.00" |

Note: Transflow Hoppers above are standard. Custom sizes and designs are available upon request.