Low Headroom

Model LH

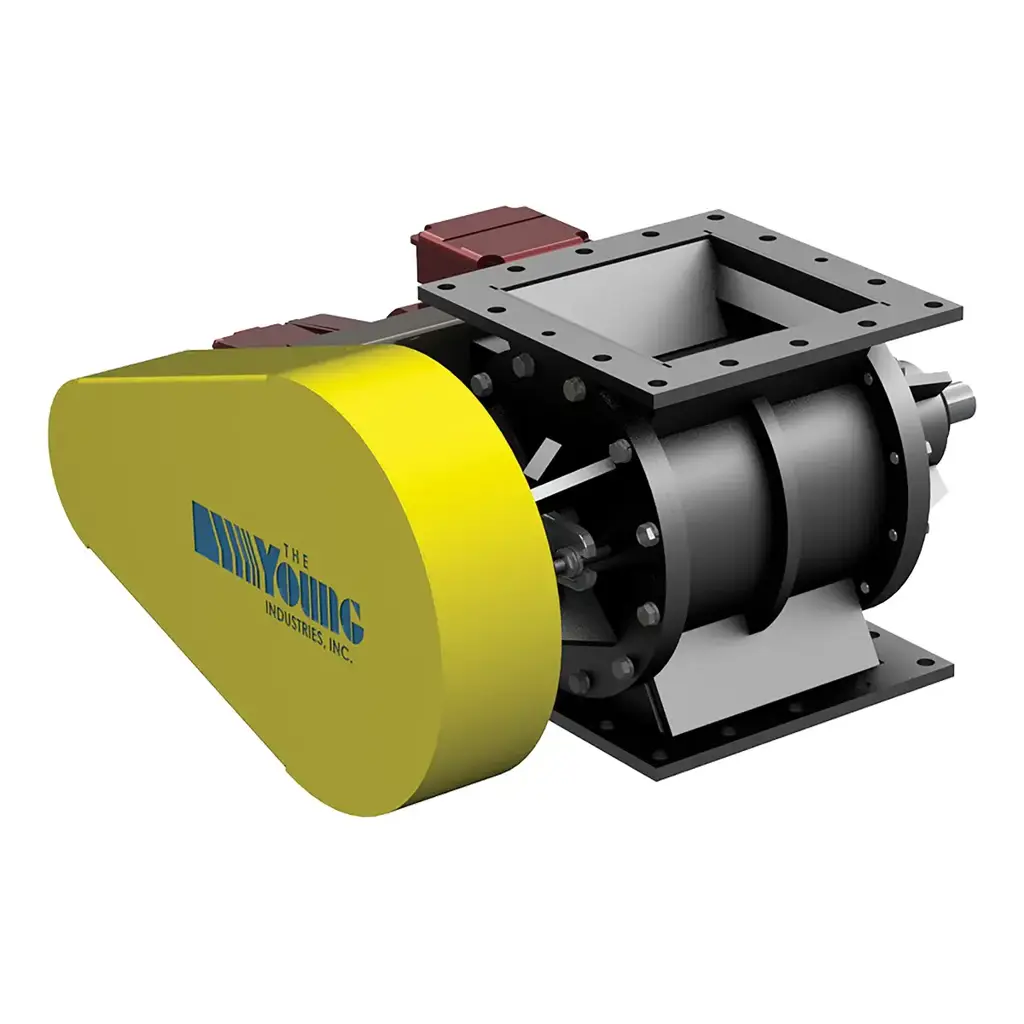

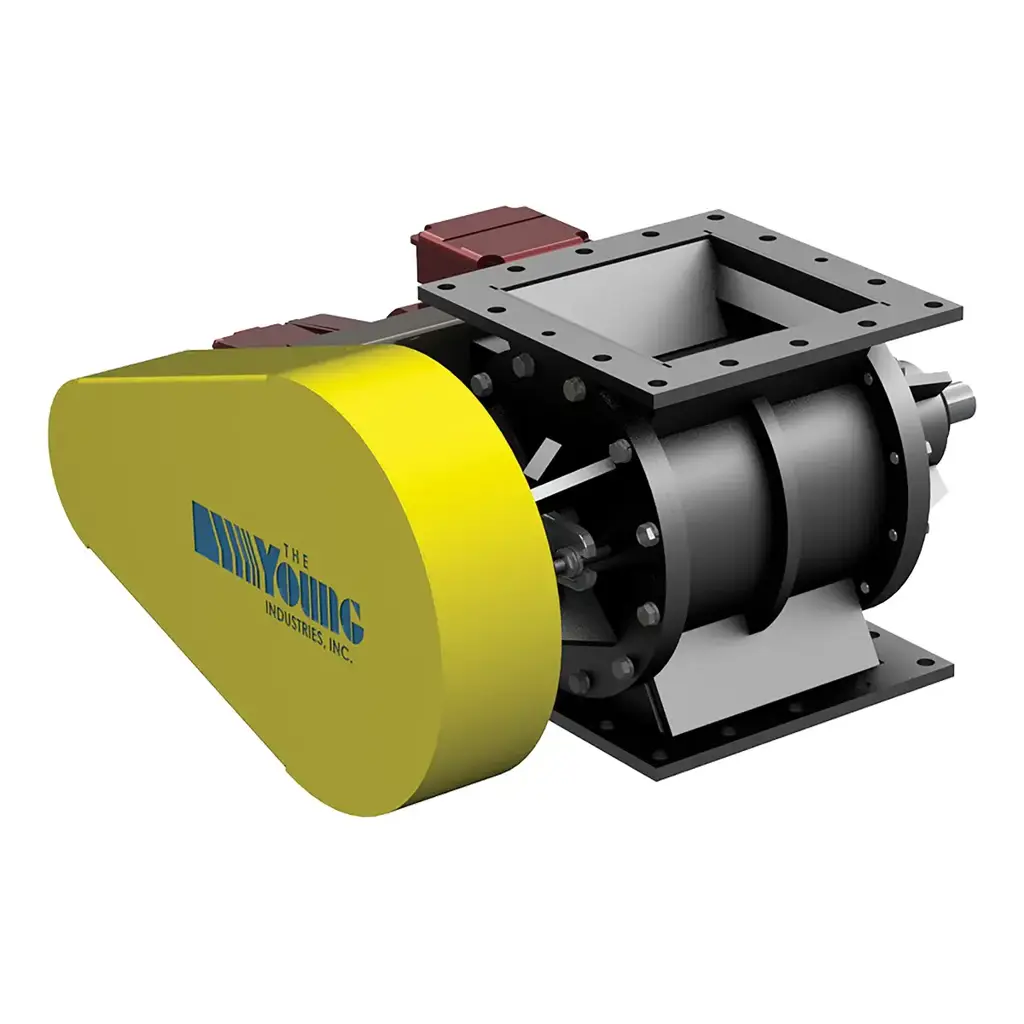

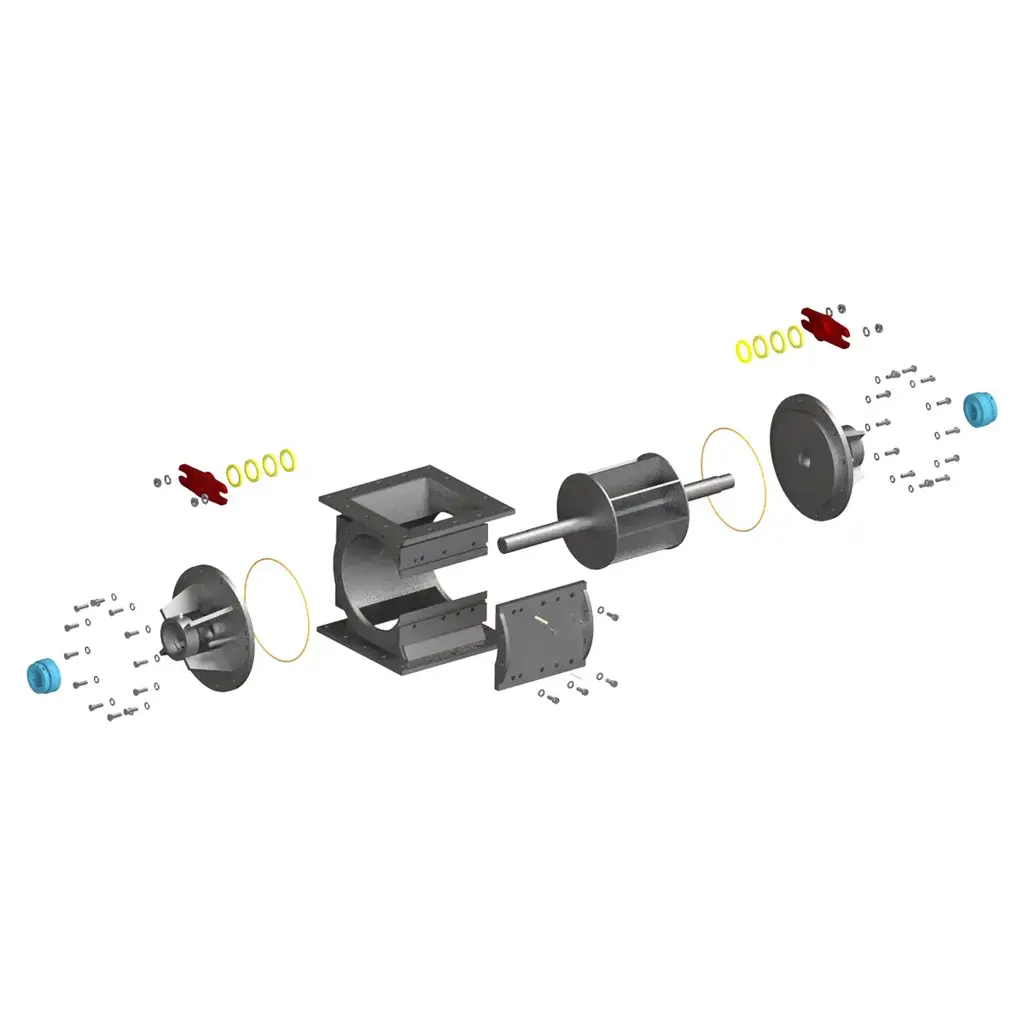

Need a rotary valve that fits in tight spaces without sacrificing performance? Young Industries Model LH (Low Headroom) Rotary Airlock Feeder Valve is your answer. We've engineered it with a low profile for applications where headroom is limited, but air-tight sealing is critical.

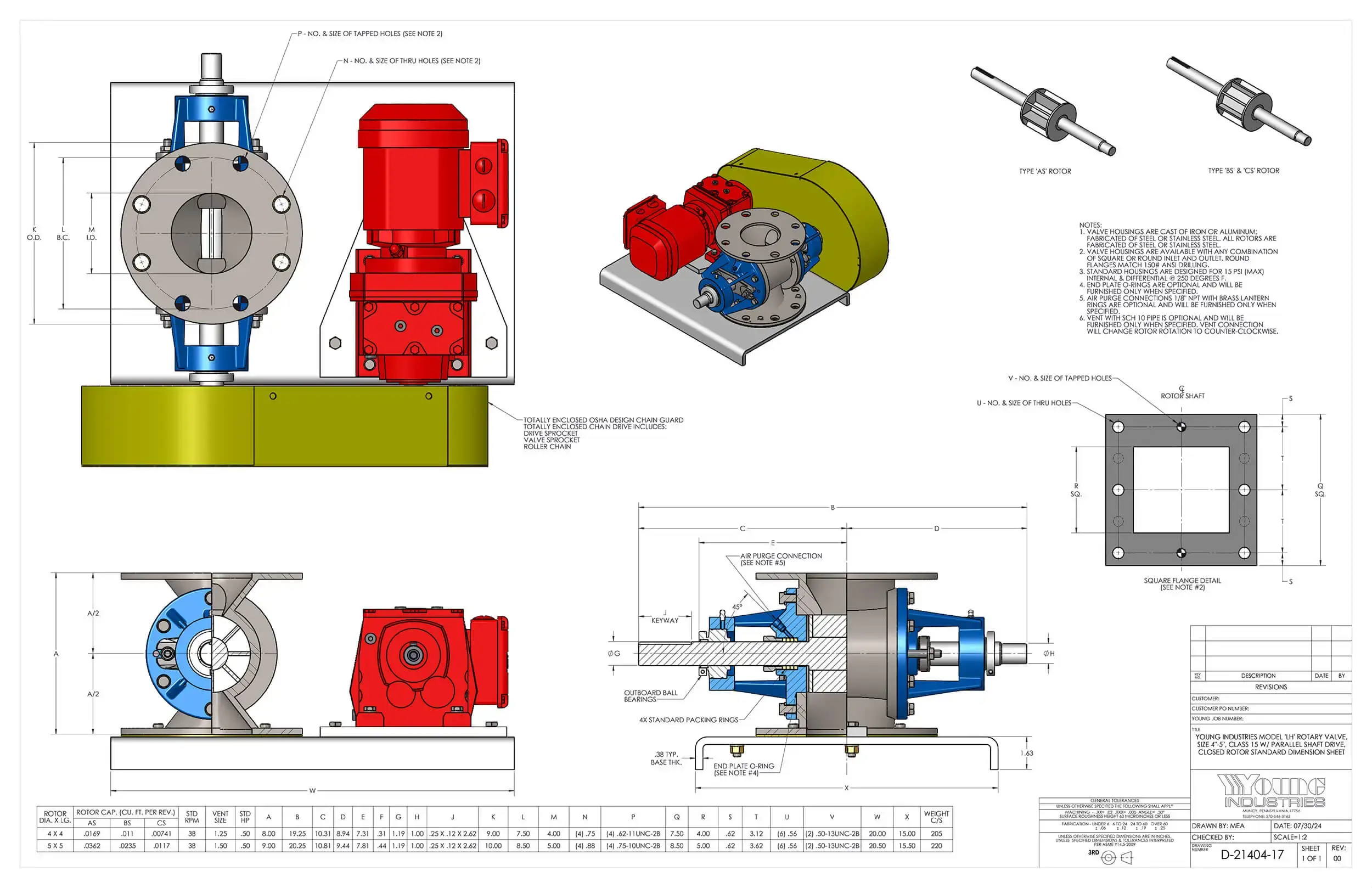

The LH Rotary Valve's design ensures minimal air or gas leakage in a compact package. Its small diameter rotor and angled inlet/outlet throats maintain that crucial two-blade seal at all times. The result? Proven performance and reliability across a wide range of bulk material handling applications, all while keeping costs down. If low headroom is a must or you've got a specific flange size to match, our LH Rotary Valve is the smart choice.

Features & Options

The Model LH Rotary Valve is available in a variety of sizes and configurations to meet your specific needs. Its low-profile design makes it perfect for applications where space is limited. Plus, with minimal air or gas leakage, it’s ideal for handling sensitive materials.

The Model LH Rotary Valve acts as a reliable airlock, preventing air or gas loss between pressure zones while allowing dry solids to flow seamlessly. With its shorter profile requiring less headroom, it is ideal for applications where volume throughput isn't a major concern.

For increased capacity without added height, the Model LH can also be furnished in a double-length configuration. With eight different rotor designs and a wide variety of features and materials of construction, we can tailor the LH Valve to your exact process requirements.

- Low headroom design

- 15 PSIG Housing and differential pressure or vacuum

- Minimum four blade sealing with two (2) blade sealing on each side

- Fabricated or cast designs

- Materials of construction: Cast or fabricated carbon steel, cast or fabricated stainless steel

- Raw materials are traceable to standard specifications with ASTM the most used specification

- Round or square inlet flange (ranging from 4" to 24")

- Round or square discharge flange (ranging from 4" to 24")

- Standard design up to 250°F operation temperature, with designs offered to withstand up to 1,000°F temperature

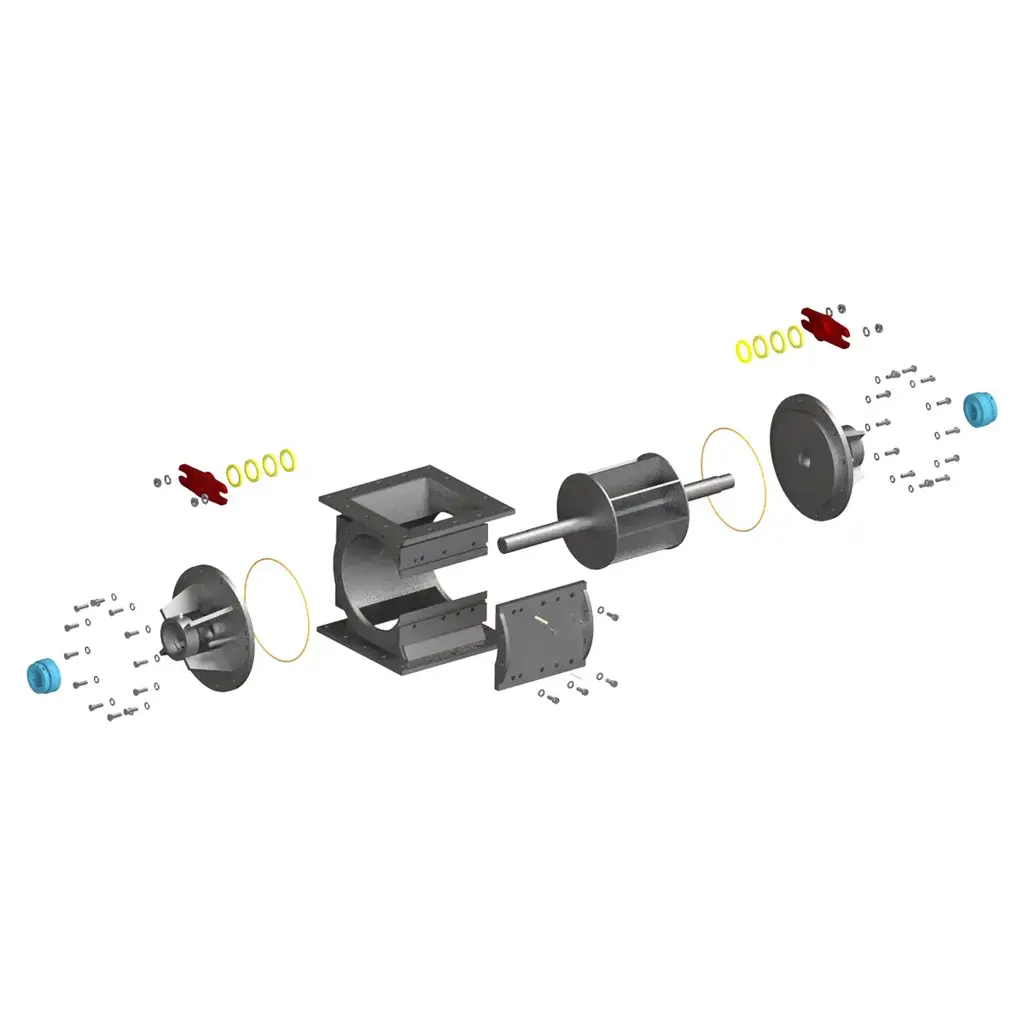

- Outboard-mounted precision ball bearings

- Packing gland rotor shaft seal consisting square braided Kevlar impregnated with PTFE packing, 4 rings per side and held in place by an aluminum packing follower.

- Eight (8) bladed rotor with twelve (12) bladed rotor for rotary valves over 12″ size to provide low operating air or gas leakage.

- Rotor assembled concentrically to the housing

- Rotor shafts secured to eliminate shifting in the housing

- Two (2) basic styles of rotors available with each style having four (4) different types of rotors (“A”- Standard, “B & C”- partially filled and “D” – adjustable tips)

- Grounding and bonding connection to NFPA specifications

- Parallel shaft gearmotor, side-mounted, 3-phase, 60 Hertz, 230-460 volts, TEFC and roller chain drive and safety to OSHA requirements.

- Painted blue epoxy

- Completely assembled and tested

- High pressure design to 150 PSIG

- High temperature design to 1,000°F

- Special 1″ to 3″ and 28″ to 36″ Sizes and double length styles available

- Drive and accessories are usually supplied consisting of a parallel shaft gear motor, sprockets, drive chain and safety guard. TEFC or Explosion proof motors, direct connected and other special drive available

- Special materials of construction including: 316 Stainless steel, Hastelloy, or Titanium

- Interior coatings (to provide abrasive resistance and material release) include: chrome plating, nickel plating, tungsten carbide, Stellite, Teflon

- Interior polishes and cleanup

- Special packing materials as graphite, food grade PTFE

- Air purge packing glands

- Lip seal packing

- Self adjusting packing follower

- Mechanical rotor shaft seals

- Shaft seal area polishes

- Inlet material deflector

- Venting thimble

- Housing vent

- End plate purges

- Rotor tips and edges beveled

- Rigid or flexible tips available

- Painted or coated per customers specification

- Transflow® fluidized rotors for cohesive powders

- Variable speed drives with 10-1 turndown

- Motion switch

- Inspection door

Specifications

| Size | Standard Speed (RPM) | Standard HP | Materials of Construction | Standard Design Temp | Standard Design Pressure |

|---|---|---|---|---|---|

| 4 | 38 | 0.5 | Carbon Steel* Stainless Steel* Aluminum* Hastelloy^ Titanium^ |

250°F | 15 PSIG |

| 5 | 38 | 0.5 | |||

| 6 | 32 | 0.5 | |||

| 8 | |||||

| 10 | |||||

| 12 | 0.75 | ||||

| 14 | 30 | ||||

| 16 | 1 | ||||

| 18 | 28 | ||||

| 20 | 1.5 | ||||

| 22 | 26 | ||||

| 24 | 24 |

*Cast or Fabricated

^Fabricated Only

Customization

The Model LH Rotary Valve can be customized to meet your specific needs. We offer a variety of options, including different rotor designs, materials of construction, and drive systems. We can also provide the valve in a double-length configuration.