Stinger® Conveyor

Our patented Stinger® Conveyor is the ultimate solution for transferring challenging materials from Bulk Bag Unloading Stations, Filter/Bag Dump Stations, or Hoppers. Whether you're working with cohesive powders, pigments, carbon black, talcs, or clays, the Stinger® Conveyor delivers reliable, gentle conveying with minimal degradation.

Our innovative TransFlow® technology precisely controls the conveying gas and conditions the product, allowing even the most stubborn materials to flow smoothly through the Stinger® Conveyor pipe.

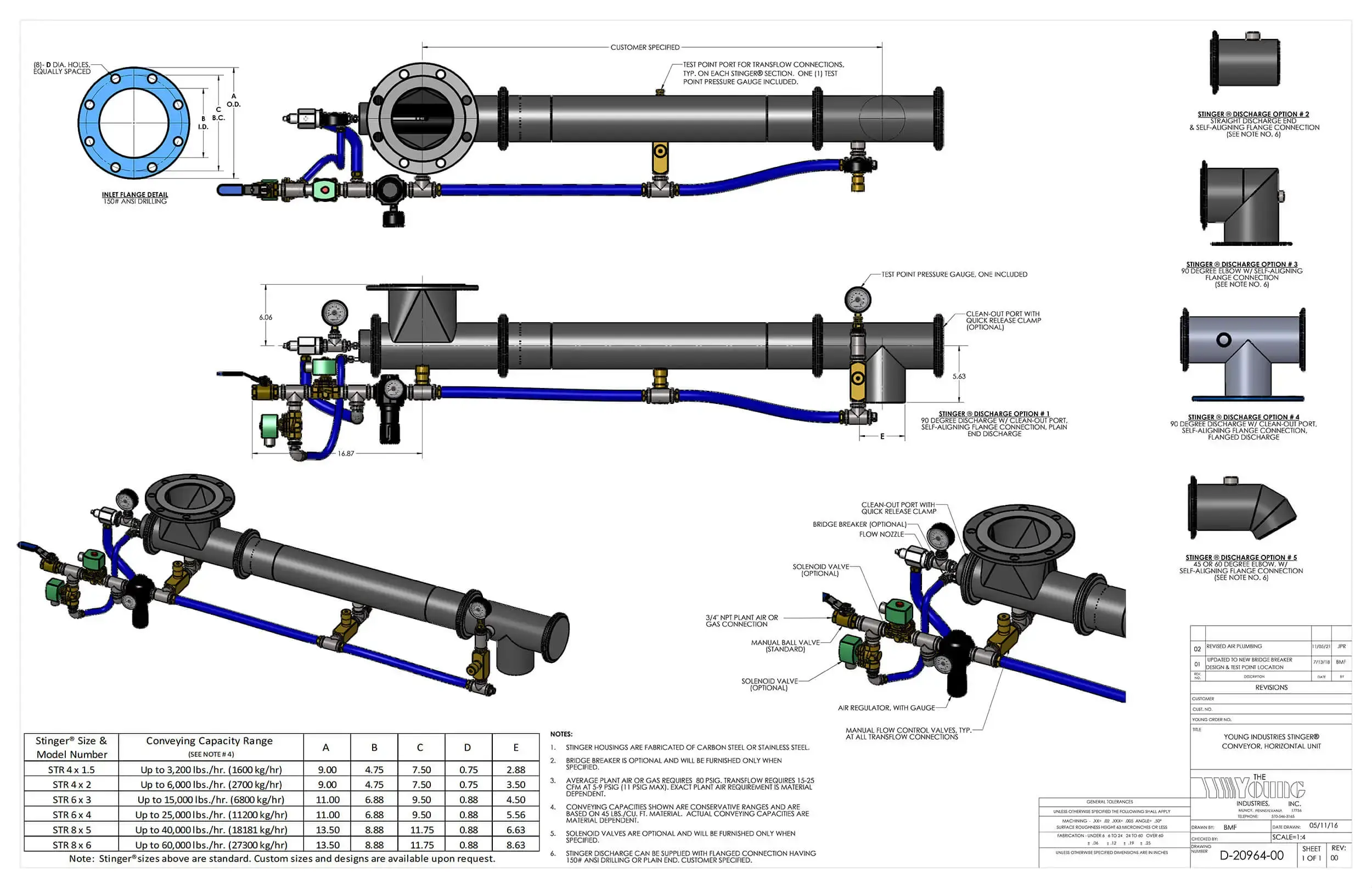

Features & Options

The Stinger® Conveyor is engineered for performance and adaptability to convey materials horizontally over distances up to 100 feet. We offer a range of features and options to meet your specific conveying needs.

- Sizes include from 1.5” to 4” diameter

- Materials for construction: carbon steel, 304 S/S, and 316 S/S and 316L S/S Transflow®

- Reduced maintenance costs with no moving parts and no high voltage

- Air or gas piping systems and controls available

- Manual on/off ball valves, automatic on/off solenoid valves, NEMA 4 or NEMA 7/9

- Flow Nozzle and/or Lump Breaker

- With or without cleanout port

- 24 VDC or 120 VAC

- Lifting lugs, support lugs, flow meters

- Manual or automatic butterfly or knife gate valves for stopping the flow of product

- Custom sizes and materials of construction available

Specifications

Model ST 1

| Feeder Tube Size | Maximum Capacity | ||

|---|---|---|---|

| Inches | mm | Lbs/Hr | Kg/Hr |

| 1.50 | 38 | 2,400 | 1,091 |

| 2.00 | 51 | 4,000 | 1,818 |

| 3.00 | 76 | 8,000 | 3,636 |

| 4.00 | 102 | 16,000 | 7,273 |

| 5.00 | 127 | 24,000 | 10,909 |

| 6.00 | 152 | 30,000 | 13,636 |

Model ST 2

| Feeder Tube Size | Maximum Capacity | ||

|---|---|---|---|

| Inches | mm | Lbs/Hr | Kg/Hr |

| 1.50 | 38 | 3,600 | 1,636 |

| 2.00 | 51 | 6,000 | 2,727 |

| 3.00 | 76 | 12,400 | 5,636 |

| 4.00 | 102 | 24,000 | 10,909 |

| 5.00 | 127 | 36,000 | 16,364 |

| 6.00 | 152 | 50,000 | 22,727 |

Resources

Customization

We offer a variety of customization options for our Stinger® Conveyors and Pumps, allowing us to tailor the perfect solution for your specific material handling challenges. Contact us today to discuss your needs and discover how we can optimize your process.