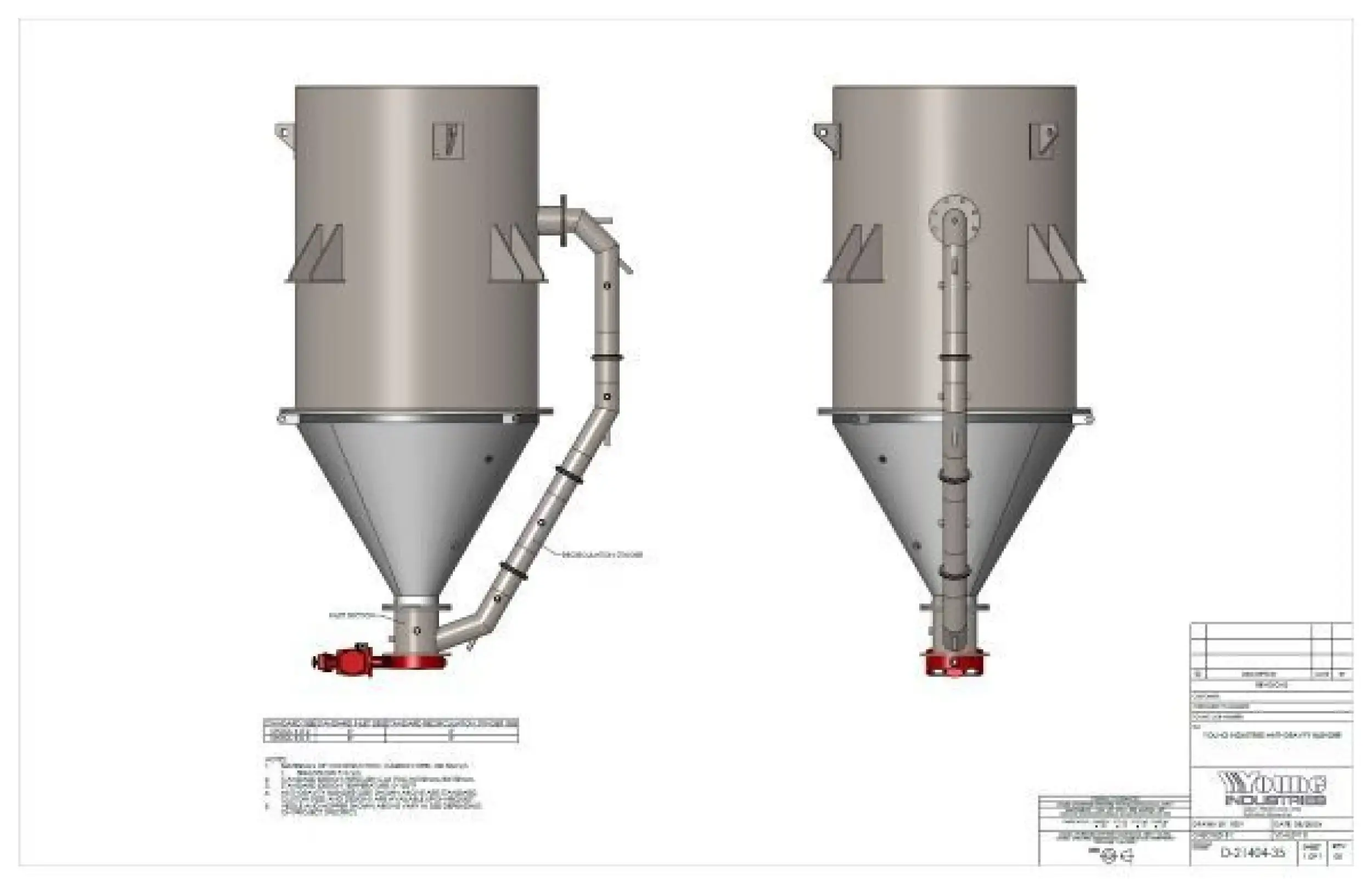

Anti-Gravity Blender

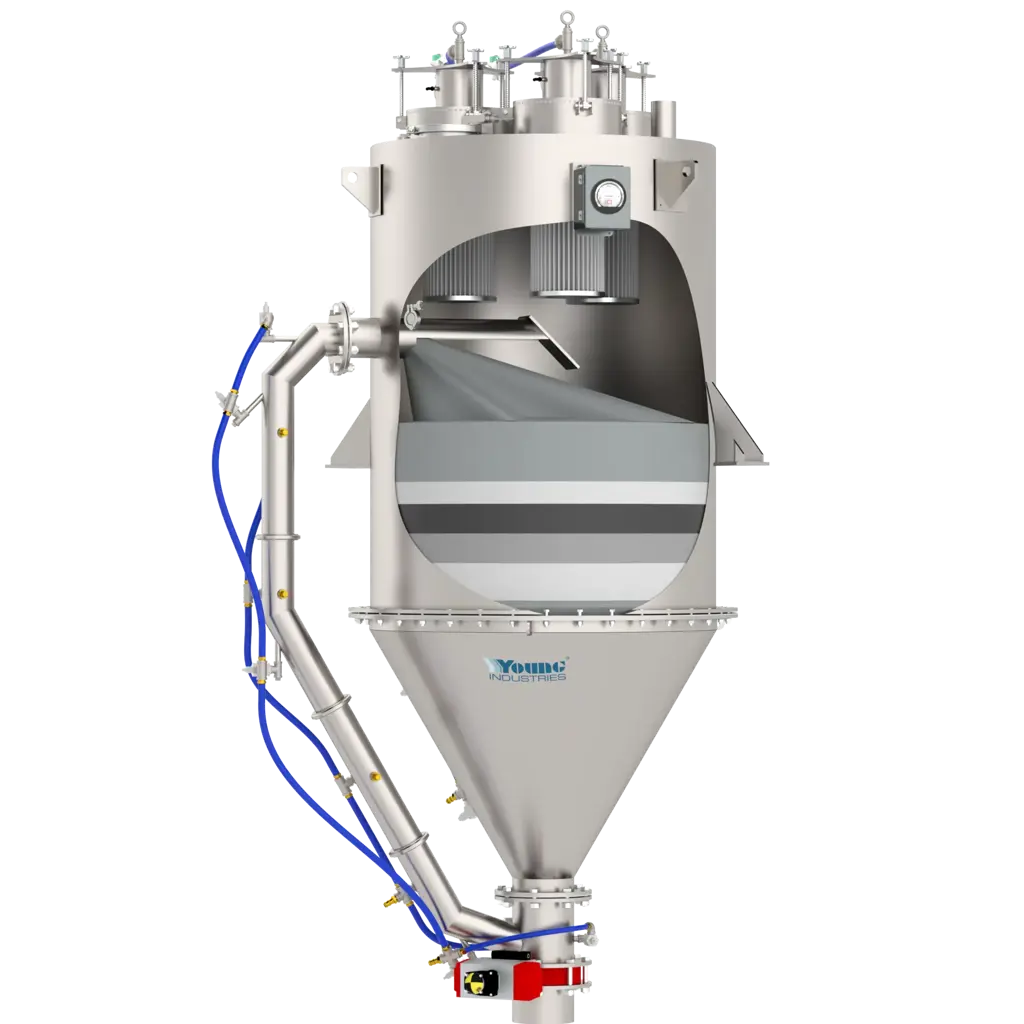

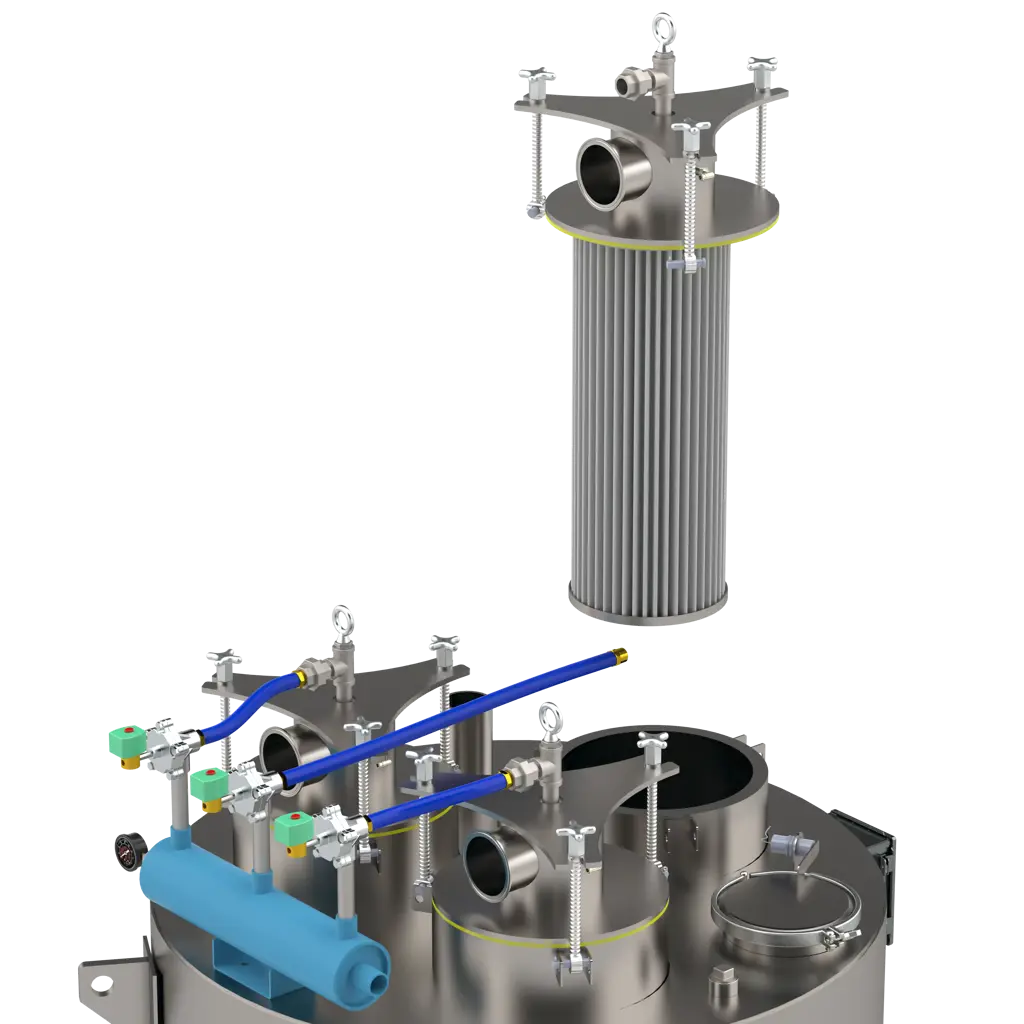

Our patented Anti-Gravity Blender offers a revolutionary approach to blending fine powders. It's gentle, energy-efficient, and cost-effective, making it ideal for even the most challenging powders with poor flow properties. Unlike traditional mechanical blenders, our system uses only low-volume, low-pressure compressed air or gas to fluidize and blend powders, resulting in a homogenous mix without the need for motor-driven or mechanical agitation.

Features & Options

Our Anti-Gravity Blenders are designed to meet your specific needs, whether you're blending in batches or continuously recirculating powders within your existing hoppers, day bins, or surge bins.

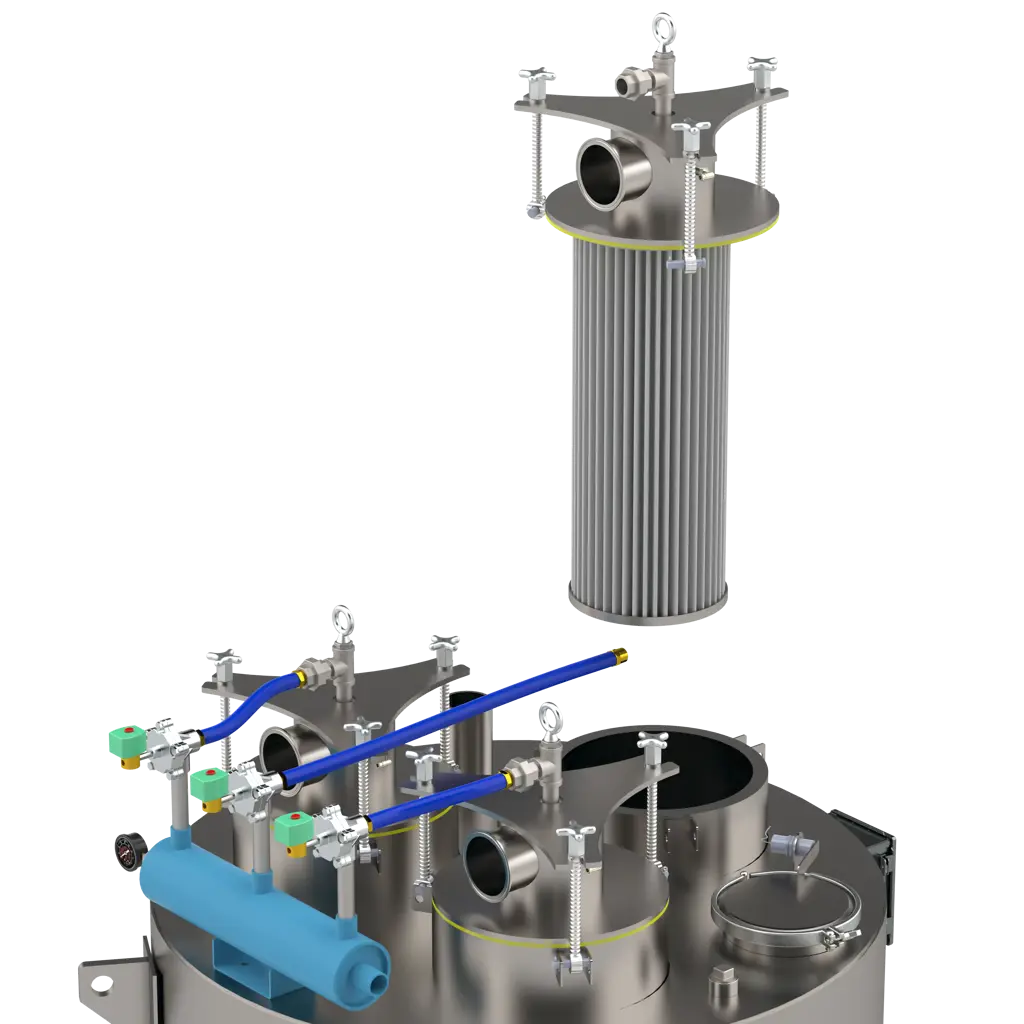

The core is a cylindrical hopper, sized to your batch capacity (from 5 ft.3 to 1200 ft.3). The hopper cone is lined with our patented TransFlow® fluidization media, ensuring gentle and effective powder conditioning before entering the blending chamber. It all ads up to a simple, yet powerful solution for achieving consistent blends on even the most cohesive powders.

- TransFlow® and Stinger® technology

- Can be retrofitted to existing hoppers, bins, and silos

- Operates on 30 PSIG compressed air

- Consumes 1-2 SCFM per foot of recirculation Stinger®

- Consumes 1-2 SCFM per square foot of TransFlow® cone

- Single central connection for compressed air and controls

- NEMA 4 solenoid valves (24 VDC or 120 VAC)

- Reliable, gentle, and effective mixing

- Increase production with higher discharge flow rates

- Reduce maintenance costs: no moving parts, high voltage, or vibration

- Reduce downtime: eliminate bridges, ratholes, and plugged outlets

- Cone angles as shallow as 30° to accommodate height restrictions

- Lifting lugs, support lugs, and level indicators or indicator connections

- Flow meters, pressure switches, and transmitters

- Bin vent filters for cleaning displaced air

- Pneumatic or mechanical systems for filling or discharge

- Manual or automatic gate valves for stopping product flow

- Compressor solutions for supplying the necessary air

- Custom design and materials of construction are available

- Special paint can be provided on the exterior of carbon steel units

Specifications

| Size | Inlet Dia. | Stinger® Dia. | Material of Construction | CFM Usage | Blending Capacity |

|---|---|---|---|---|---|

| 6 X 2 | 6" | 2" | Carbon Steel or Stainless Steel Body TransFlow® 316L S/S WPC |

40-75 | Up to 30 cu. ft. |

| 8 X 3 | 8" | 3" | 100-150 | Up to 150 cu. ft. | |

| 10 X 3 | 10" | 3" | 175-250 | Up to 500 cu. ft. | |

| 10 X 4 | 10" | 4" | 250-350 | 500 cu. ft. and larger |

Note: Anti-Gravity Blender sizes above are standard. Custom sizes and designs are available upon request. Vessel, cone, and Stinger® are sized depending on the specified blending capacity needed and material characteristics.

Customization

Our team of experts will collaborate with you to design an Anti-Gravity Blender system that perfectly suits your material properties, batch sizes, and facility layout. Contact us today to discuss your specific requirements and discover how we can optimize your blending process.