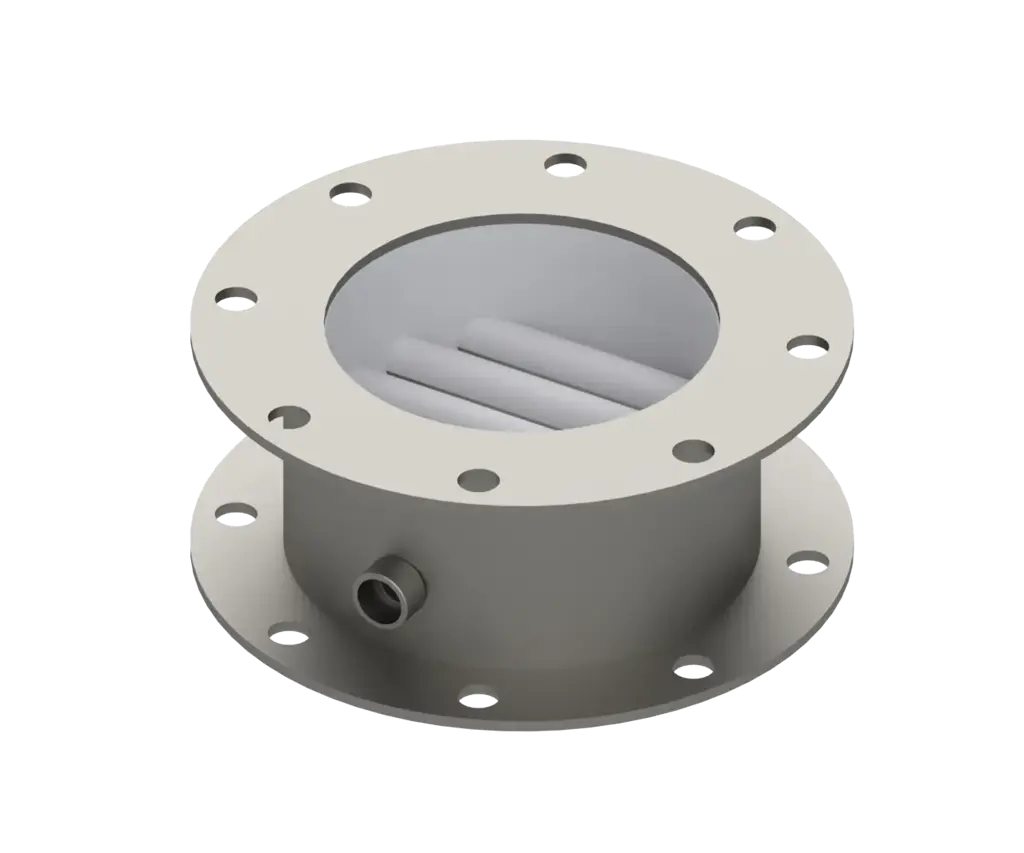

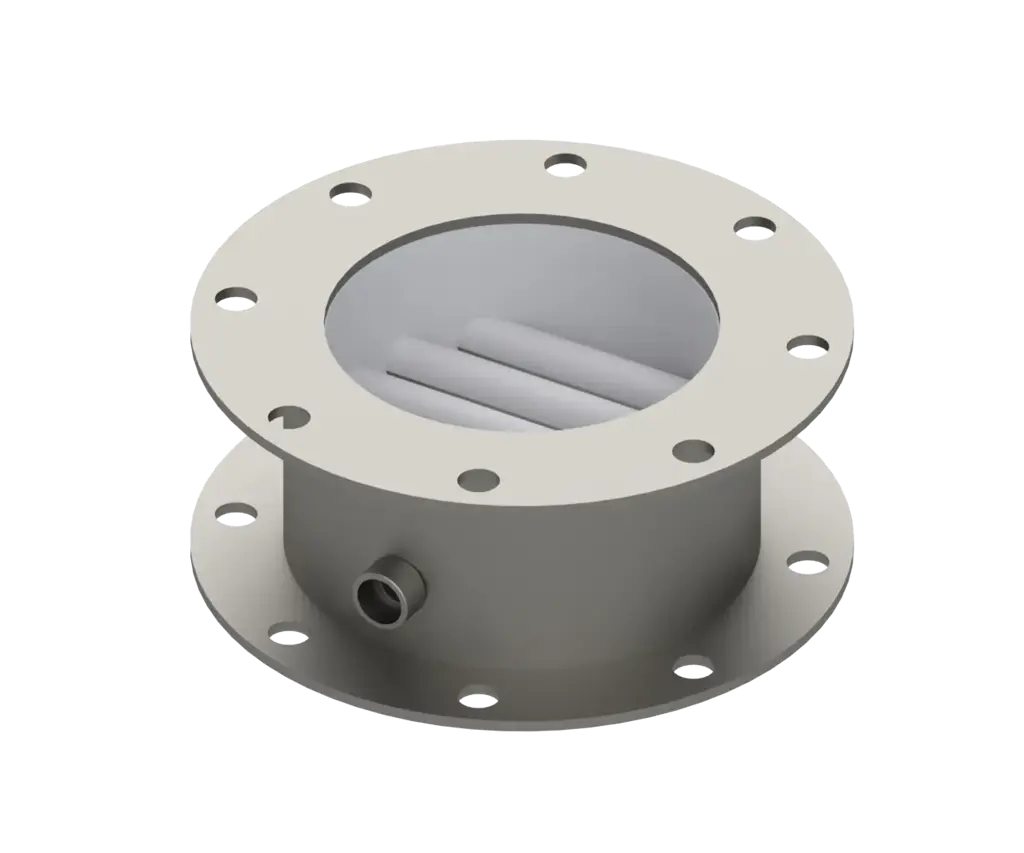

SafetyFlow® Grate Fluidizes Powders

Powder handling gratings designed to eliminate bridging and protect your operator

SafetyFlow Grating

Our SafetyFlow® Grating is more than just a protective barrier — it's a proactive manufacturing solution that enhances both employee safety and process productivity. When you work in an industrial environment, providing access to powder product areas while preventing material buildup and safeguarding operators from rotating equipment can be a challenge. The Young Industries SafetyFlow Grating has you covered, offering reliable physical protection from hazards while enhancing powder flow, even with fine or cohesive materials.

Features & Options

We've engineered SafetyFlow Grating with your toughest challenges in mind, combining robust construction with TransFlow technology to deliver reliable protection and improved material flow. This innovative solution is ideal for various applications where personnel protection and material flow are critical, such as:

-

Rotary Valve Discharge: Prevent accidental contact with the rotor when removing drums for disposal.

-

Screw Conveyor Inlets: Protect operators from rotating helixes during operation or maintenance.

-

Bulk Bag Unloading Stations: Safeguard personnel from pinch points while accessing the bag spout. The grating also enhances powder flow, unlike traditional bar grates that can cause buildup.

- Bolted-in-place design for secure installation

- No need for safety interlocks or switches that can be overridden

- Bar spacing designed to prevent access to hazards based on distance

- Round, square, or rectangular configurations

- Customizable length and width to fit any application

- Variable bar spacing to protect against hands, elbows, or shoulders, depending on the distance from the hazard

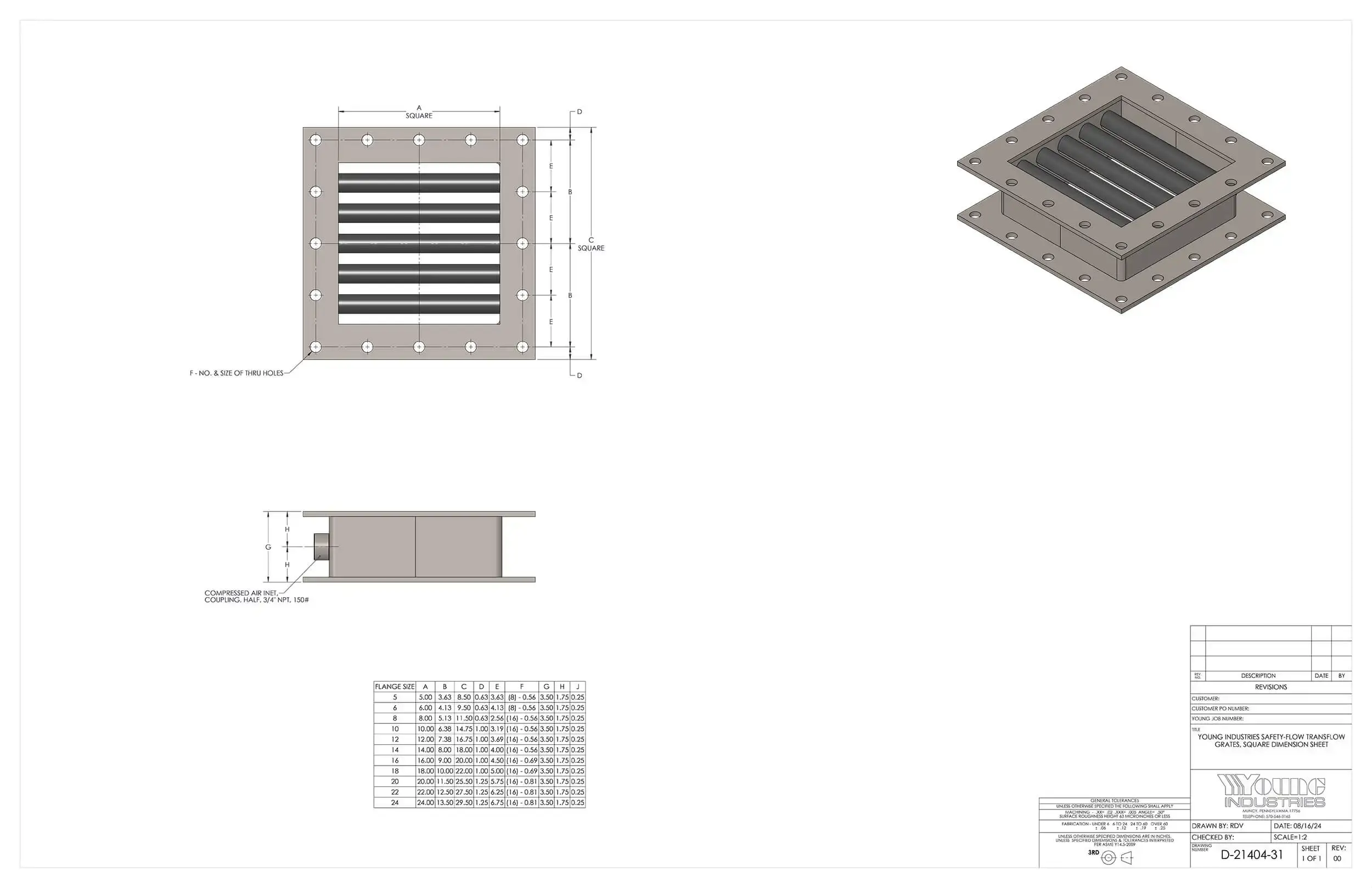

Specifications

Round

| Size | I.D. (in.) | O.D. (in.) | Number of Bars | Open Space Between Bars (in.) | OAH (in.) |

|---|---|---|---|---|---|

| 5 | 5 | 10 | 3 | 0.56 | 5.5 |

| 6 | 6 | 11 | 4 | ||

| 8 | 8 | 13.5 | 5 | ||

| 10 | 10 | 16 | 7 | 0.5 | |

| 12 | 12 | 19 | 8 | 0.56 | |

| 14 | 14 | 21 | 9 | ||

| 16 | 16 | 23.5 | 11 | 0.5 | |

| 18 | 18 | 25 | 12 | 0.56 | |

| 20 | 20 | 27.5 | 13 | ||

| 24 | 24 | 32 | 16 |

Square

| Size | I.D. (in.) | O.D. (in.) | Number of Bars | Open Space Between Bars (in.) | OAH (in.) |

|---|---|---|---|---|---|

| 5 | 5 | 8.5 | 3 | 0.56 | 3.5 |

| 6 | 6 | 9.5 | 4 | ||

| 8 | 8 | 11.5 | 5 | ||

| 10 | 10 | 14.75 | 7 | 0.5 | |

| 12 | 12 | 16.75 | 8 | 0.56 | |

| 14 | 14 | 18 | 9 | ||

| 16 | 16 | 20 | 11 | 0.5 | |

| 18 | 18 | 22 | 12 | 0.56 | |

| 20 | 20 | 27.5 | 13 | ||

| 22 | 22 | 27.5 | 14 | ||

| 24 | 24 | 29.5 | 16 |

Customization

We offer customization options for our SafetyFlow Grating, including tailored sizes, bar spacing, and materials of construction. Our team of experts will work with you to design a grating that perfectly fits your equipment and safety requirements, ensuring both operator protection and optimal material flow.