Fluidizing

Model EV

Metering cathode and anode materials is a critical step in battery production. Inconsistent flow, adhesion, and settling can lead to uneven distribution, impacting battery quality and performance.

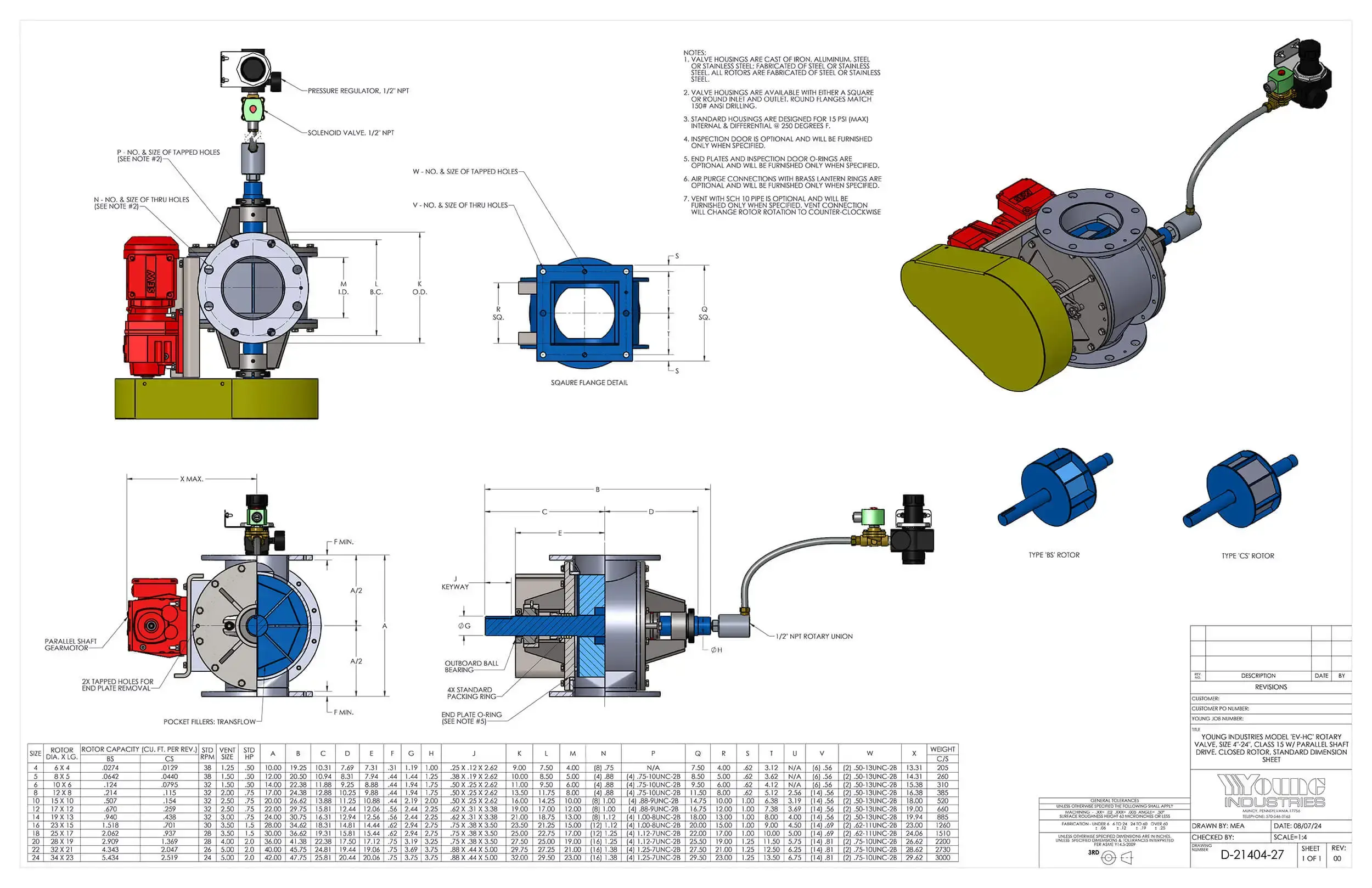

The Young Industries Model EV Rotary Valve is your solution for precise, reliable metering of cohesive battery materials. We've combined our rugged rotary valve design with our innovative TransFlow® aeration technology to prevent sticking and ensure consistent flow in even the most demanding conditions.

The Model EV Valve is engineered to handle carbon black, graphite, nickel-based powders, and lithium-based powders with ease.

Features & Options

Say goodbye to the headaches of metering challenging battery materials. The Model EV Rotary Valve ensures smooth, consistent flow, even with the most stubborn powders.

The rotor pockets are lined with TransFlow®, a porous material that fluidizes the material when low-pressure compressed gas or air is supplied to its backside. This creates a non-stick surface, ensuring reliable material release and preventing blockages. The result? Increased production efficiency, reduced downtime, and of course: improved battery quality.

While designed for EV battery manufacturing, the Model EV's versatility shines in any industry where cohesive materials pose a challenge.

- TransFlow® lined rotor for material fluidization and release

- Heavy duty construction with 15 PSIG internal and differential pressure rating

- Constructed of carbon steel or 300 series stainless steel

- Standard design/operating temperature up to 250°F

- Round, square, or custom inlet and discharge flanges

- Outboard-mounted precision ball bearings

- Packing gland provides a tight rotor shaft seal with four rings of PTFE impregnated Kevlar

- End plates are piloted to assure concentricity of the housing so that tight internal clearances between rotor and housing is provided

- Air flow controls for TransFlow®

- All stainless steel control components

- Motion speed switch

- VFD inverter

- Explosion proof electrical components

- Teflon lantern ring with purge connection in the packing gland

- High internal pressure designs up to 50 PSIG

- High temperature designs up to 500°F

- Roller chain drive with parallel shaft TEFC driven gearmotor is standard with explosion proof motors of any specified manufacturer available

- Special packing materials of graphite, food grade PTFE, or as needed by process.

- Direct venting with vent installed in the housing

- End plate purges

- Rotor tips and edges can be beveled

- End plate o-rings

- Shrouded or open rotors with standard or filled pockets

- Exterior painting and coatings to meet customer specifications

- Shaft mounted drive

Specifications

| Size | Standard Speed (RPM) | Standard HP | Materials of Construction | Standard Design Temp. | Standard Design Pressure |

|---|---|---|---|---|---|

| 4 | 38 | 0.5 | Carbon Steel* Stainless Steel* Aluminum* Hastelloy^ Titanium^ |

250°F | 15 PSIG |

| 5 | |||||

| 6 | 32 | ||||

| 8 | 0.75 | ||||

| 10 | |||||

| 12 | |||||

| 14 | |||||

| 16 | 30 | 1.5 | |||

| 18 | 28 | ||||

| 20 | 2 | ||||

| 22 | 26 | ||||

| 24 | 24 |

*Cast or Fabricated

^Fabricated Only

Customization

Your battery manufacturing process is unique. That's why we offer a range of customization options for the Model EV Rotary Valve. From specialized air flow controls to explosion-proof electrical components, we'll configure your valve to meet your specific needs and safety requirements. Need a particular flange size or material of construction? No problem. We'll collaborate with you to design a solution that integrates seamlessly into your production line and delivers optimal performance. Let's build the perfect Model EV Valve for your process.