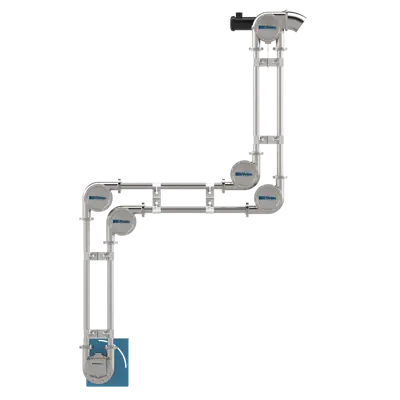

Model VHV

The Model VHV is built for adaptability, making it a standout in aero-mechanical conveying. With options for both top and bottom drive configurations, this conveyor is ready to meet the needs of diverse material handling applications. Its adjustable outlet angles and robust construction ensure reliable performance across industries. Ideal for installations where flexibility is key, the VHV seamlessly integrates into your production line while maintaining the high-speed efficiency of aero-mechanical technology.

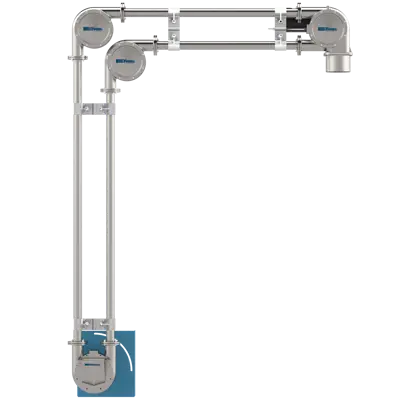

Model VH

For applications requiring a vertical-to-horizontal material flow, the Model VH is the right-angle conveyor built for the task. Designed to convey vertically and discharge horizontally at adjustable angles, the VH is ideal for installations where space is limited. This unit combines the efficiency of aero-mechanical technology with a compact design, delivering reliable performance without sacrificing floor space.

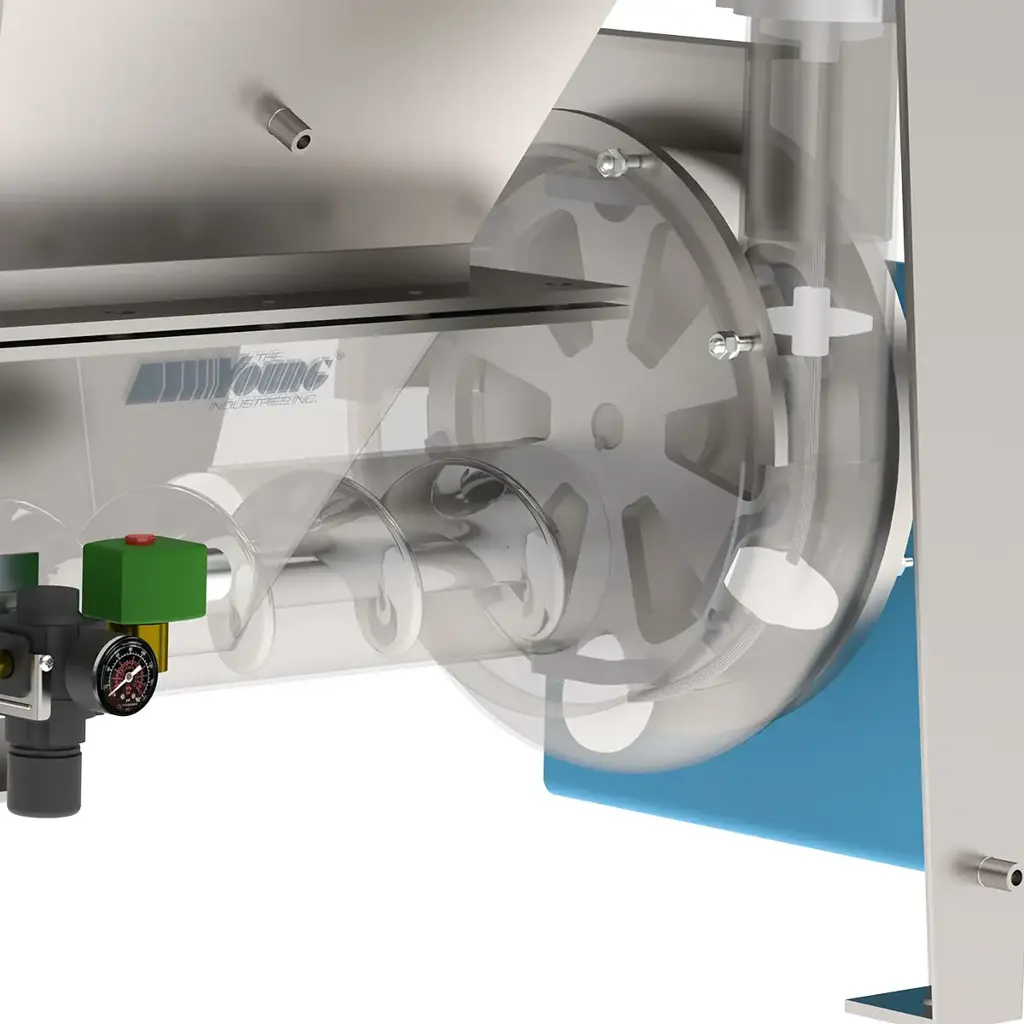

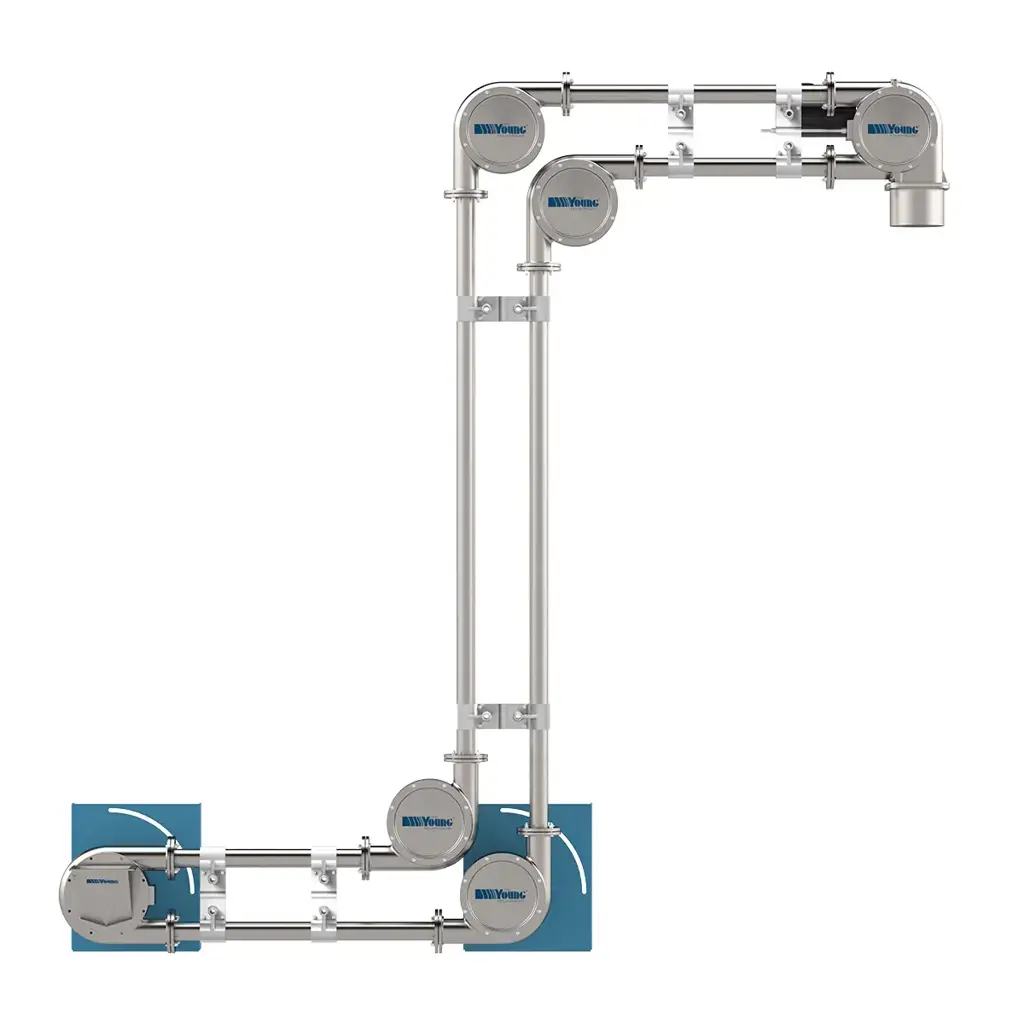

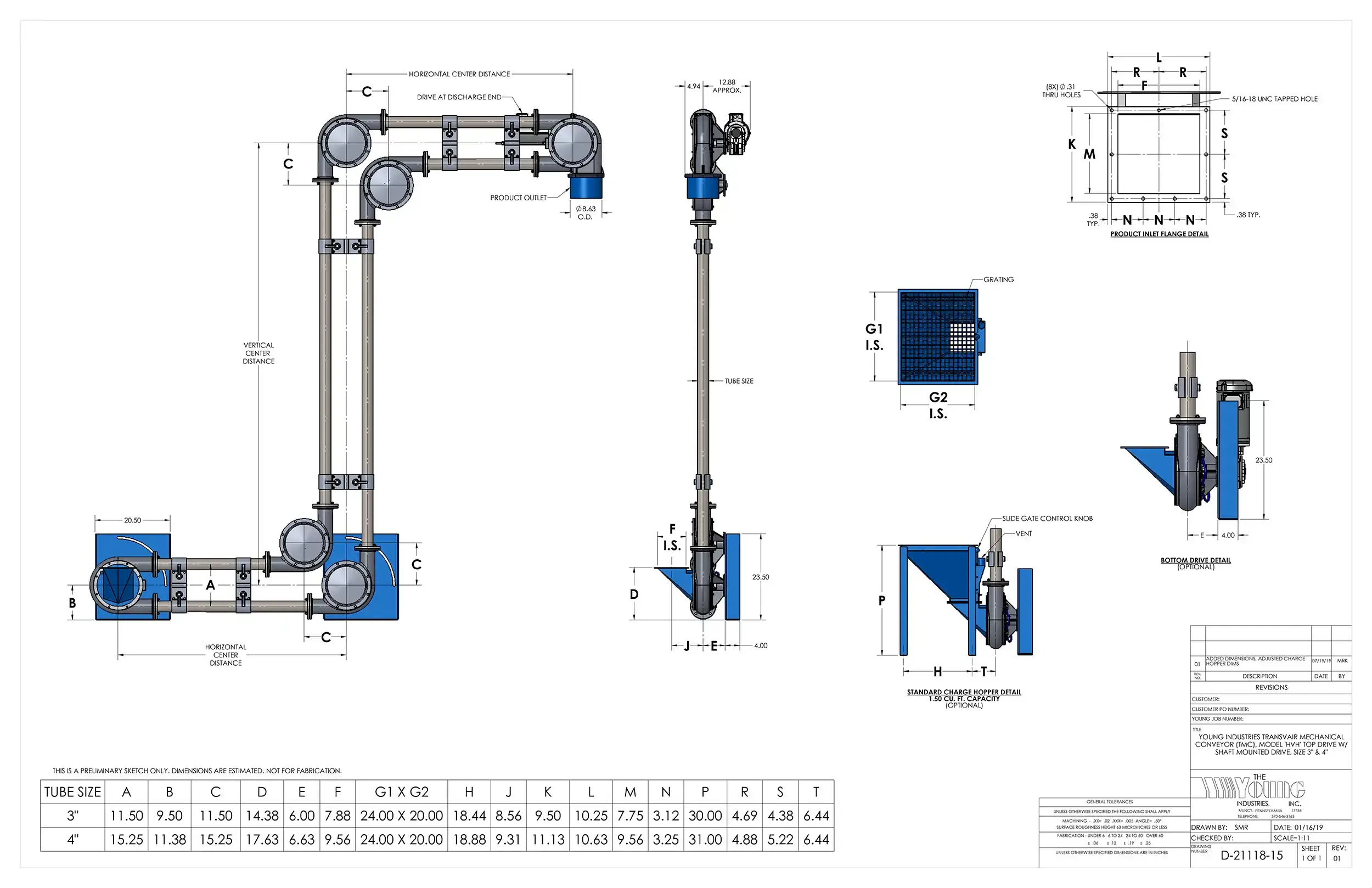

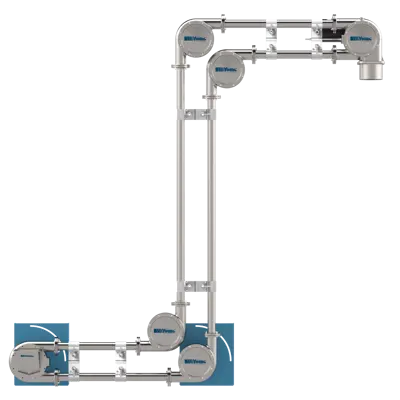

Model HVH

The Model HVH is a dependable solution for straightforward conveying applications. With a discharge-end drive system, this unit focuses on delivering materials along a direct, linear flow path. Its precision engineering supports seamless integration with existing systems, while its compact design makes it perfect for operations where simplicity is paramount. The HVH maintains the velocity and efficiency that define aero-mechanical conveyors, ensuring consistent, trouble-free performance.

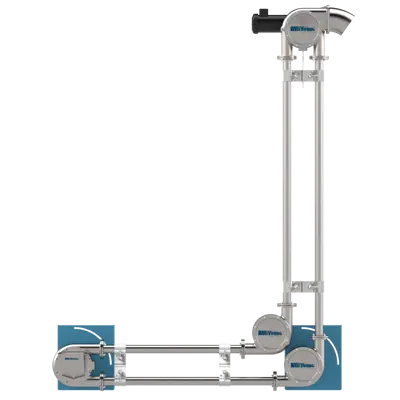

Model HV

The Model HV takes right-angle conveying to the next level. Engineered to transition materials from horizontal to vertical flow seamlessly, this unit is built for installations where efficiency and adaptability are paramount. With its top-drive design and adjustable outlet angles, the HV delivers consistent performance while optimizing floor space. It’s the ideal choice for operations that demand both precision and power.

Model SL

The Model SL is the simplest and most versatile unit in the Transvair line, offering the ability to convey materials at any angle from horizontal to vertical without compromising capacity or efficiency. Its streamlined, straight-line design is perfect for installations requiring precise and flexible material handling. Whether operating in compact or expansive setups, the SL ensures reliable, high-speed performance that keeps your processes moving forward.

Configurations

The Transvair Aero-Mechanical Conveyor is available in several standard configurations. Each unit is engineered to consume minimal floor space. Length and configuration is unit specific and each conveyor is engineered to meet the service conditions of the application.

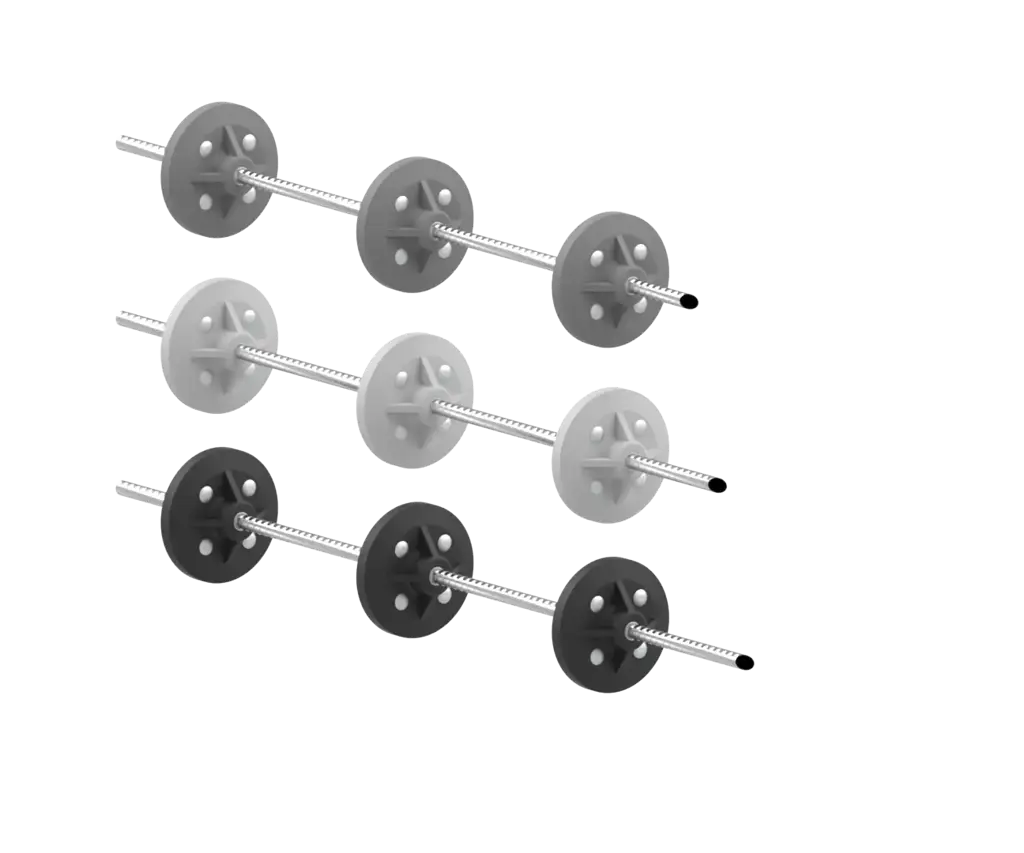

Rope Assemblies

We use a unique heat-treating process that strengthens rope ferrules, creating an effective and secure locking system for the conveyor discs, and reducing rope stress. The extra-wide ferrules provide greater surface contact with the rope for stability and load distribution.

Young Industries has developed special fixtures and testing equipment ensuring every rope assembly meets our expectations and well-documented quality control standards.

- Nylon (Various Grades)

- Polyurethane

- Carbon Filled Static Dissipating Polyurethane

- Metal Detectable Nylon

- Galvanized

- 300 Series Stainless Steel

- Plastic Coated