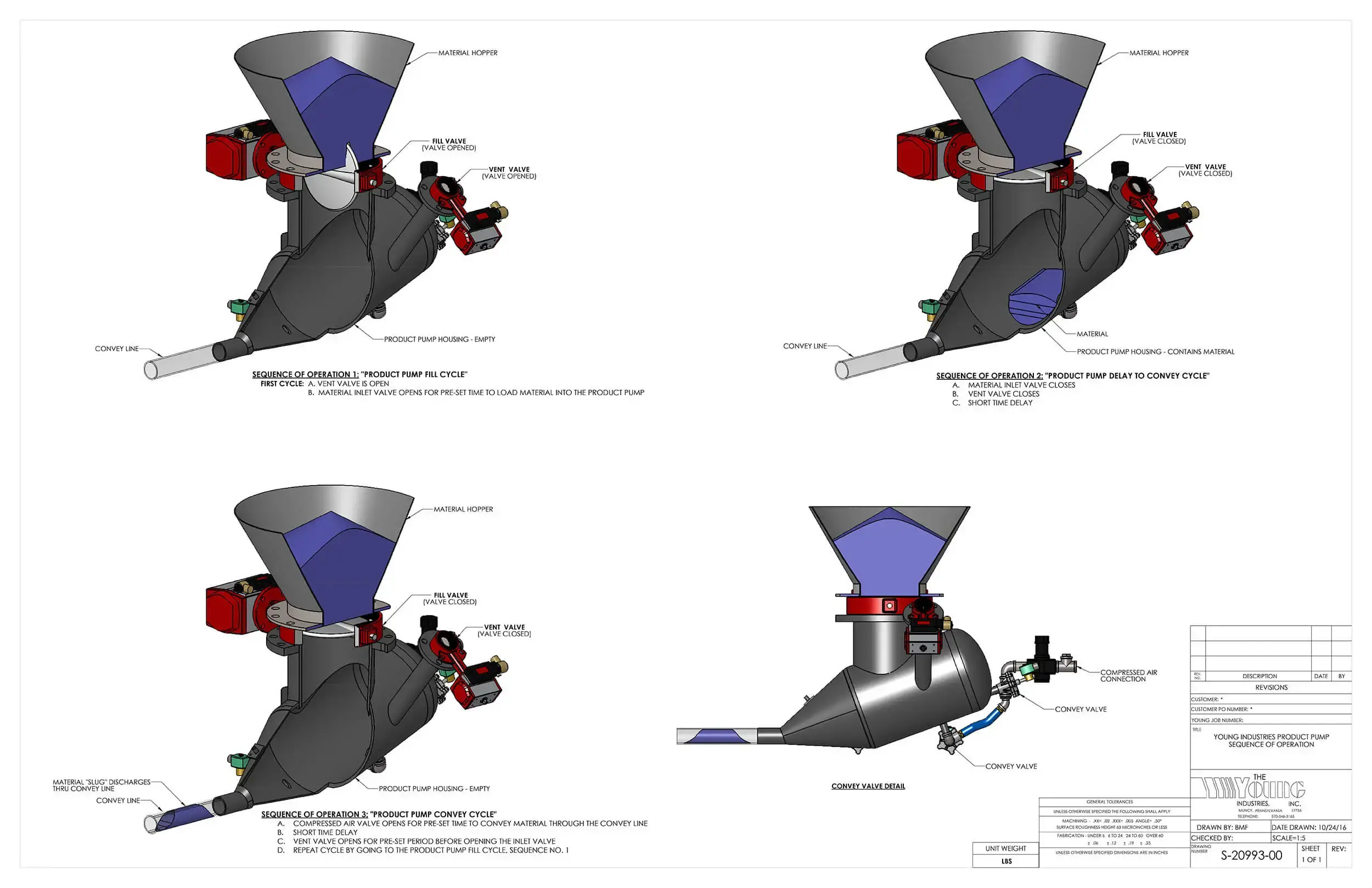

Standard Operating Sequence

The Multi-Phase Product Pump operating cycle starts when the inlet butterfly valve opens to allow the product to gravity flow into the vessel. The valve closes, and the compressed gas starts conveying the product through the convey line. After the convey cycle, the Product Pump is vented, and the operation is repeated for transfer of product.

Model PH

Horizontal design used in areas with very limited headroom. Size 206-50: for use in a 2" convey system, unit complete with a 6" flanged product inlet. Size 306-50: for use in a 3" convey system, unit complete with a 6" flanged product inlet.

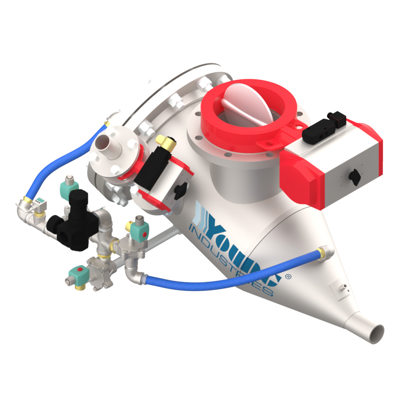

Model PI

Inclined design with good clean-out capabilities between cycles and typically used for most applications. Size 206-50: for use in a 2" convey system, unit complete with a 6" flanged product inlet. Size 306-50: for use in a 3" convey system, unit complete with a 6" flanged product inlet. Size 208-125: for use in a 2" convey system, unit complete with an 8" flanged product inlet. Size 308-125: for use in a 3" convey system, unit complete with a 8" flanged product inlet. Size 310-125: for use in a 3" convey system, unit complete with a 10" flanged product inlet.

Model PV

Vertical design with excellent clean-out between cycles, for use with products with bulk densities under 20 lb./cu. ft.. Size 208-350: for use in a 2" convey system, unit complete with an 8" flanged product inlet. Size 308-350: for use in a 3" convey system, unit complete with an 8" flanged product inlet.