Transvair Venturi Eductor

The Young Industries Transvair® Venturi Eductor system provides a cost-effective and dependable solution for conveying powdered or pelletized materials in the chemical, petrochemical, food, ceramic, glass, and paint industries.

Venturi Eductors offer several advantages over traditional rotary valves. They use plant compressed air or gas, positive displacement or regenerative blowers for the motive air, eliminating issues like air blowback and pellet clipping, and ensuring smooth material flow while reducing maintenance needs.

Features & Options

Transvair Venturi Eductors are designed for simplicity and performance, offering a range of features and options to meet your specific conveying needs. These systems are best suited for pneumatically conveying powdered or pelletized material in applications requiring transport rates under 3,000 lbs/hr and distances up to 300 feet. Venturi Eductors help you reduce maintenance costs since they have no moving or rotating parts and can operate without needing to vent and filter dusty air associated with rotary valve venting.

Commonly used on the discharge of bag dump stations, funnels receiving product from screw feeders, or on the discharge of open hoppers, Venturi Eductors and the conveying systems integration can be sized and matched by our team of pneumatic conveying experts.

- Self-feeding design can be set up to operate as metering device by regulating the air supply pressure

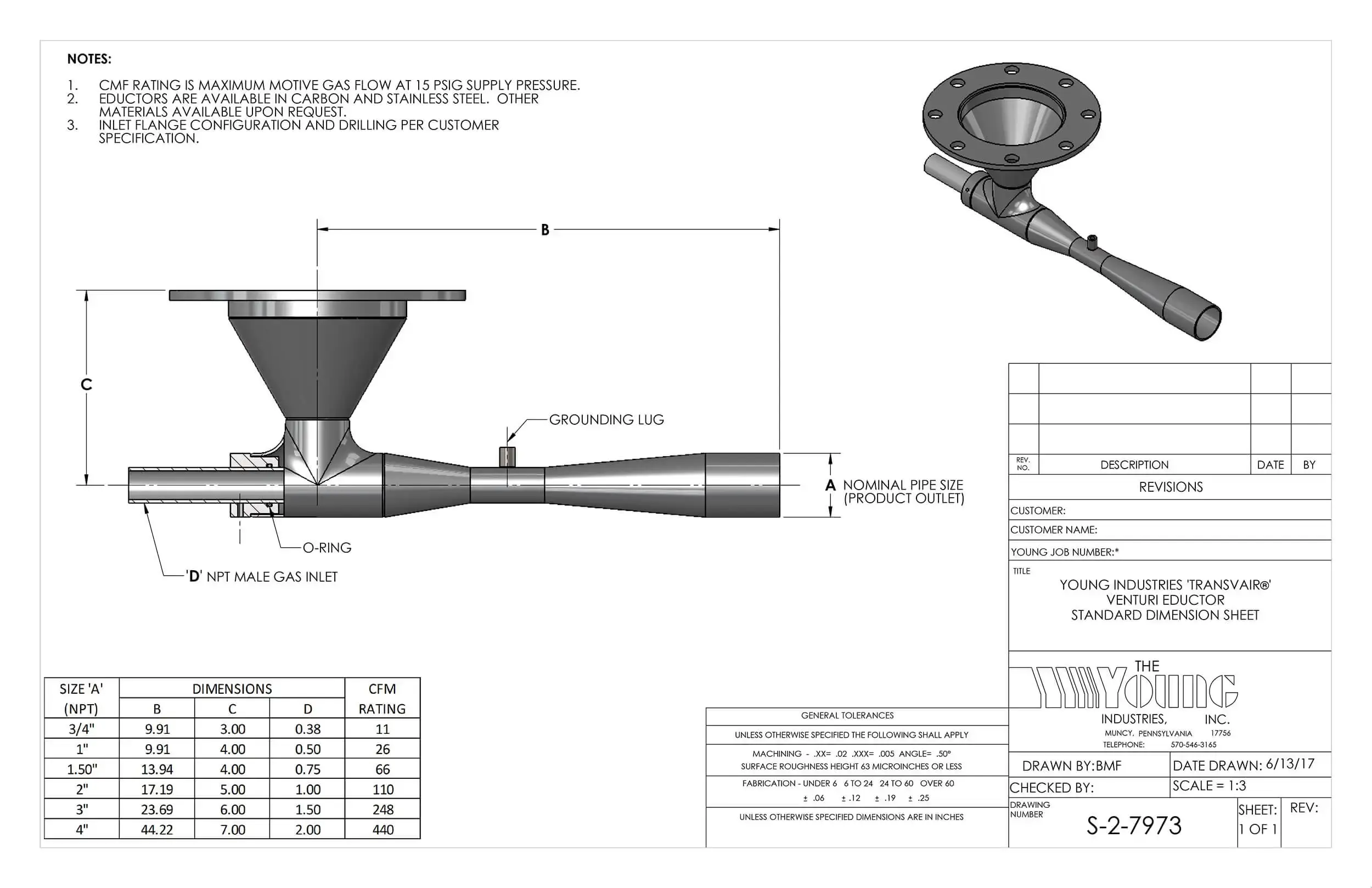

- Standard Venturi Eductor sizes for ¾” to 4” convey lines

- Plain-end product outlets for schedule 10 and 40 pipe or OD tubing are standard.

- Flanges can be provided

- Standard materials for construction include carbon steel, 304 Stainless Steel, and 316 Stainless Steel

- Operating temperatures up to 250°F are standard, with units capable of operating at higher temperatures available

- Young Industries Venturi Eductors operate on up to a 15 PSIG, clean, dry compressed air, or gas supply

- Various product inlet sizes and flange configurations

- Air or gas supply piping systems and controls can be supplied

- Compressors, positive displacement or regenerative blowers for supplying the motive air

- Manual on/off ball valves or automatic on/off solenoid valves are available for use on Venturi Eductors operating on compressed air or gas

- NEMA 4 or NEMA 7/9 Solenoid valves that operate on 24 VDC or 120 VAC

- Flow meters, pressure switches and transmitters can be added to any Eductor air or gas supply piping

- Bin Vent filters, Filter Receivers, or cyclone separators for cleaning conveying air

- Receiving bins

- Manual or automatic butterfly or knife gate valves for stopping the flow of product

- Special paint colors on the exterior of carbon steel units

Specifications

| A (Pipe Size) | CFM Rating | O-Ring Materials | Inlet Flanges | Conveying Capacity | Conveying Distance |

|---|---|---|---|---|---|

| 3/4 | 11 | Buna-N, Viton, Silicone | 150# Flat-Faced, 150# Raised Face |

6000 lbs. / hr. | Up to 300 ft. |

| 1 | 26 | ||||

| 1.5 | 66 | ||||

| 2 | 110 | ||||

| 3 | 240 | ||||

| 4 | 440 |

Resources

Customization

From specialized materials and finishes to integrated controls and accessories, we'll configure the perfect solution to meet your specific material handling needs.