Cantilevered

Model CA

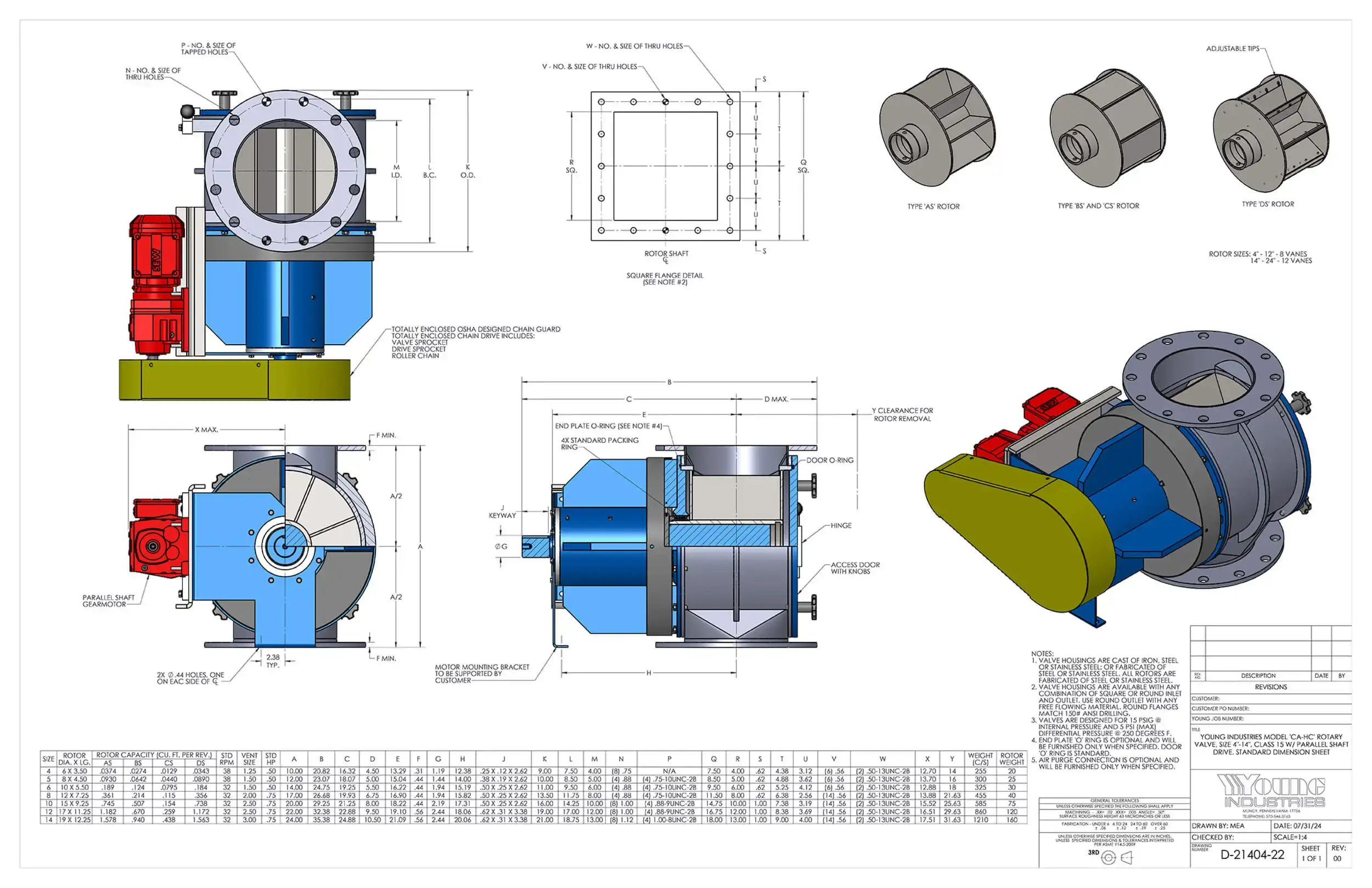

Young Industries Quick Clean Rotary Valves offer a unique cantilevered design with two bearings on one end of the rotor shaft, engineered to allow complete access to the valve interior for cleaning. The rotor itself is cantilevered from the bearings on the shaft and is completely removable from the valve on the opposite end of the housing. The housing is provided with the removable end plate cover for easy access to the valve interior and removal of the rotor.

Simply pull the rotor off the shaft and completely remove from the rotary valve assembly for cleaning.

Features & Options

The Modal CA Rotary Valve uses a chevron shaft seal assembly which is attached to the rotor. This feature allows the shaft seal of the valve to be removed with the rotor for maintenance or cleaning as needed. The Model CA Rotary Valve is used for the most sanitary applications where no tools are needed for complete disassembly of product contact parts.

The valve can be furnished in the end seal design for those applications required reduced air or gas leakage across the valve. Our cantilevered high capacity (HC-CA) and low headroom (LH-CA) models have received 3A Dairy Approval as clean-in-place valves.

The Model CA Rotary Valve has two outboard tapered roller bearings on one side of the rotor with a hinged bolt-in-place access door on the other side. The rotor shaft is sealed by four PTFE Chevron seal rings located on the drive hub that can be adjusted with the packing follower nut and drive pin. These valves are available with a wide variety of features to handle a wide range of process requirements.

- Heavy-duty construction with 15 PSIG design with 5 PSI differential

- Cast or fabricated construction of carbon steel or 300 series stainless steel

- Round or square flanged connections

- Standard design/operating temperature up to 250°F

- Precision outboard bearings

- Rotor is completely removable from the valve

- Shaft seal using chevron seal rings are attached to the rotor and removable with the rotor

- Open access to valve interior

- Removable access door with hand knobs

- Interior polish or electro-polish per application requirement

- Hinged access cover

- For larger valves, removable rotor davit/puller available

- Rotor tips can be beveled

- Replaceable rotor tips of flexible or abrasion-resistant materials

- Roller chain drive with parallel shaft TEFC gearmotor is standard with explosion-proof motors of any specified manufacturer available

- Exterior painting and coatings to meet customer specifications when needed

Specifications

Model CA-HC

| Size | Standard Speed (RPM) | Standard HP | Materials of Construction | Standard Design Temp. | Standard Design Pressure |

|---|---|---|---|---|---|

| 4 | 38 | 0.5 | Carbon Steel* Stainless Steel* |

250°F | 15 PSIG |

| 5 | |||||

| 6 | 32 | ||||

| 8 | 0.75 | ||||

| 10 | |||||

| 12 | |||||

| 14 |

Model CA-SE

| Size | Standard Speed (RPM) | Standard HP | Materials of Construction | Standard Design Temp. | Standard Design Pressure |

|---|---|---|---|---|---|

| 4 | 30 | 0.5 | Carbon Steel* Stainless Steel* |

250°F | 15 PSIG |

| 5 | |||||

| 6 | |||||

| 8 | 0.75 | ||||

| 10 | 28 | ||||

| 12 | 1 | ||||

| 14 |

*Cast or Fabricated

Resources