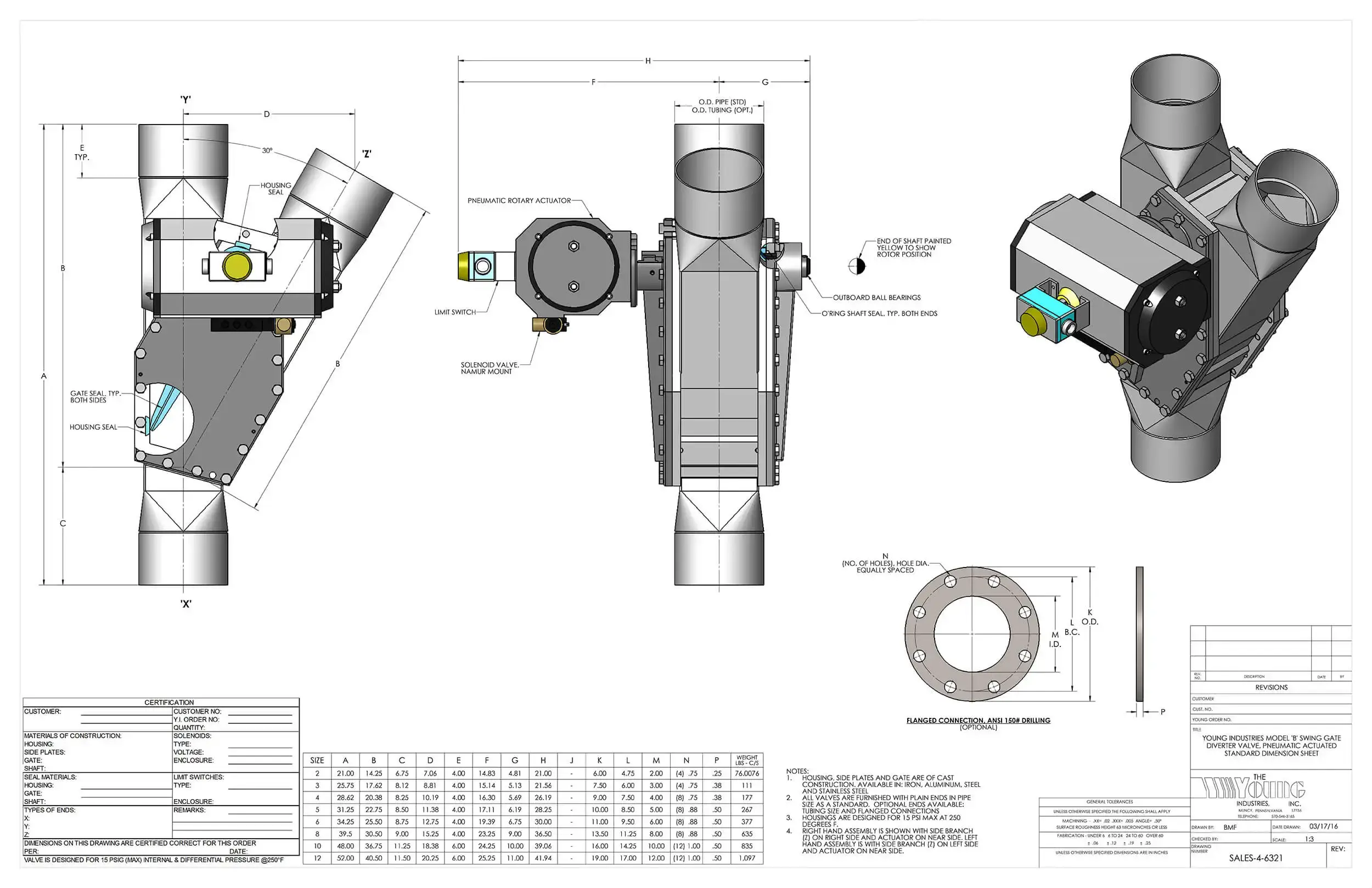

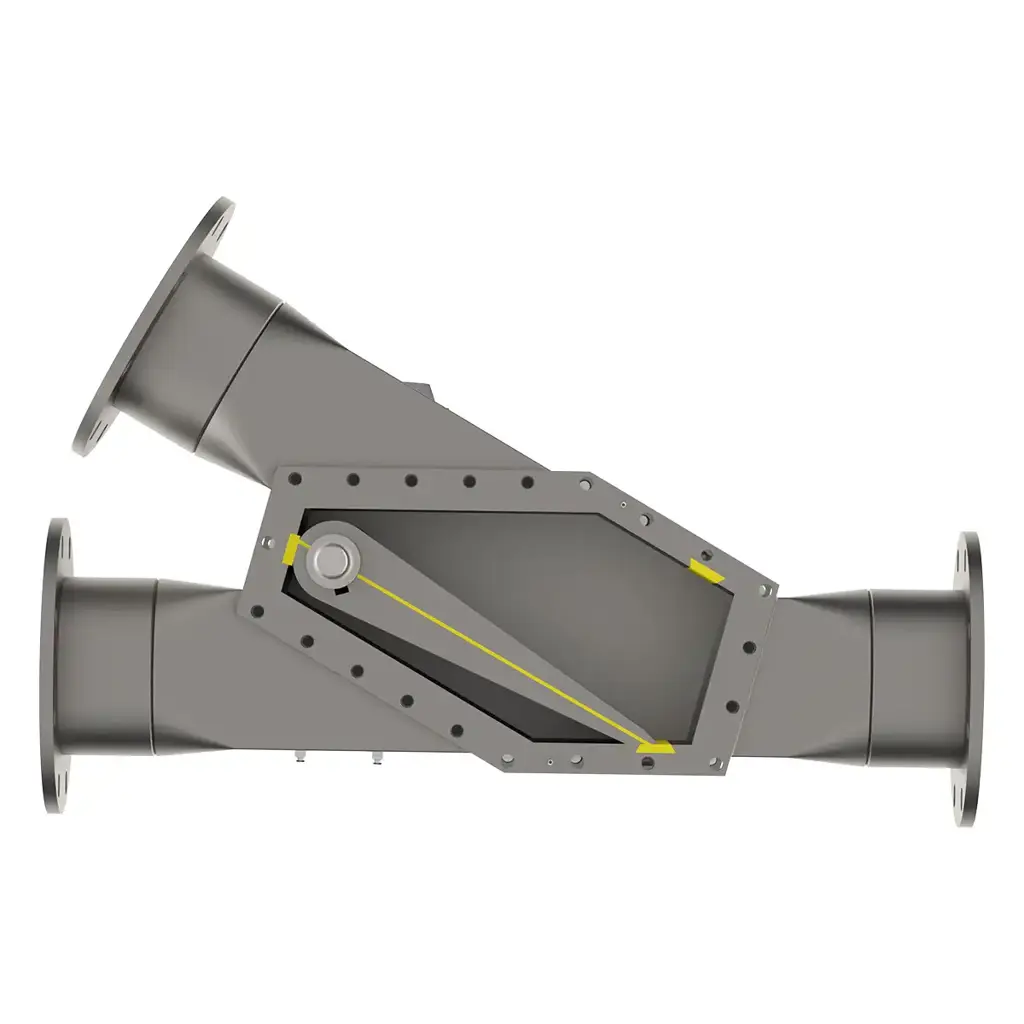

Asym. Swing Gate

Model B Diverter

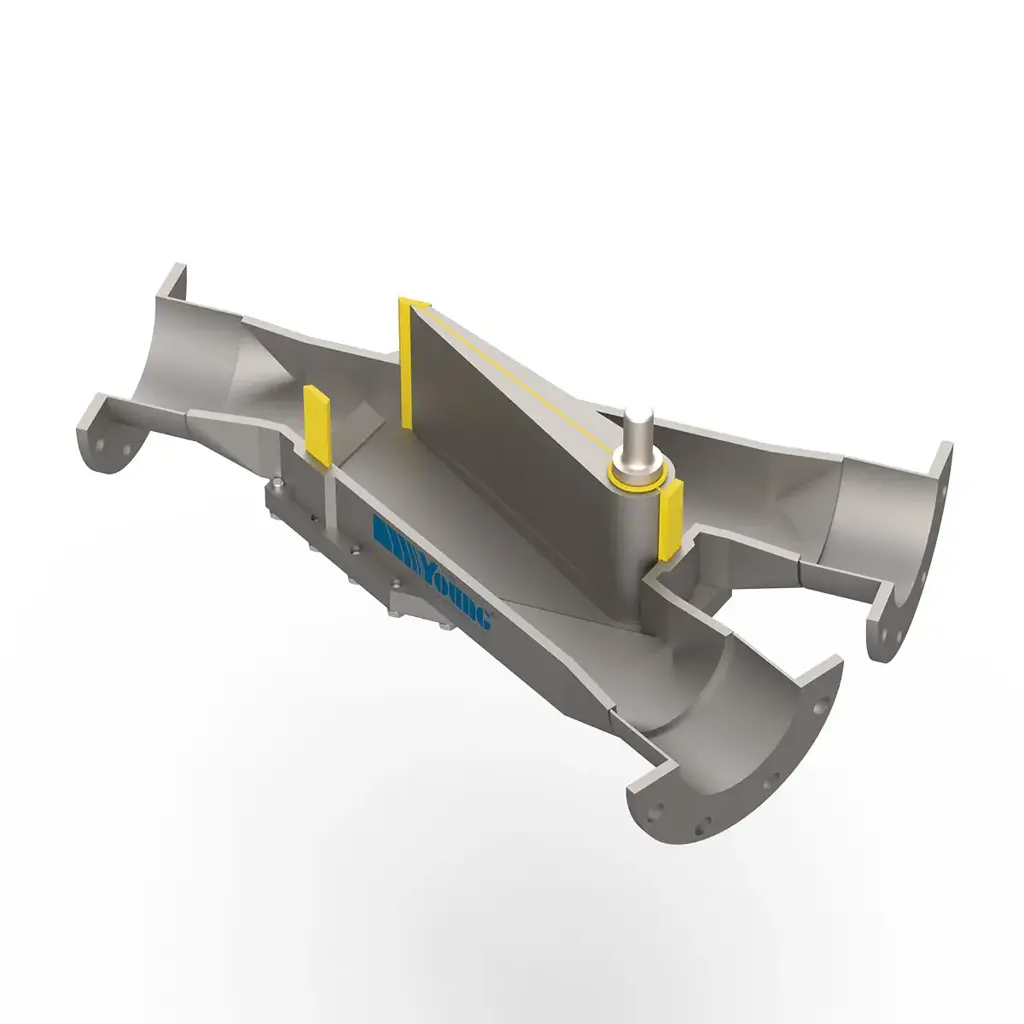

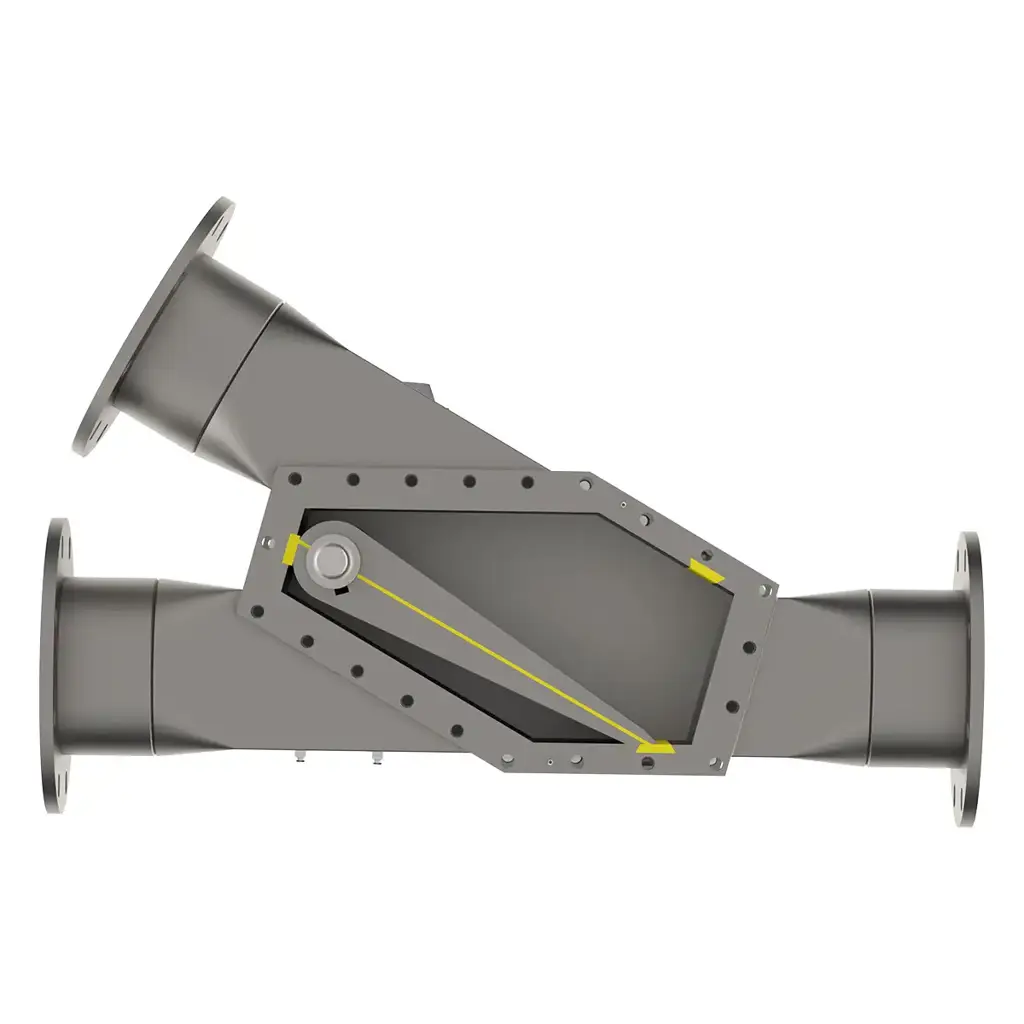

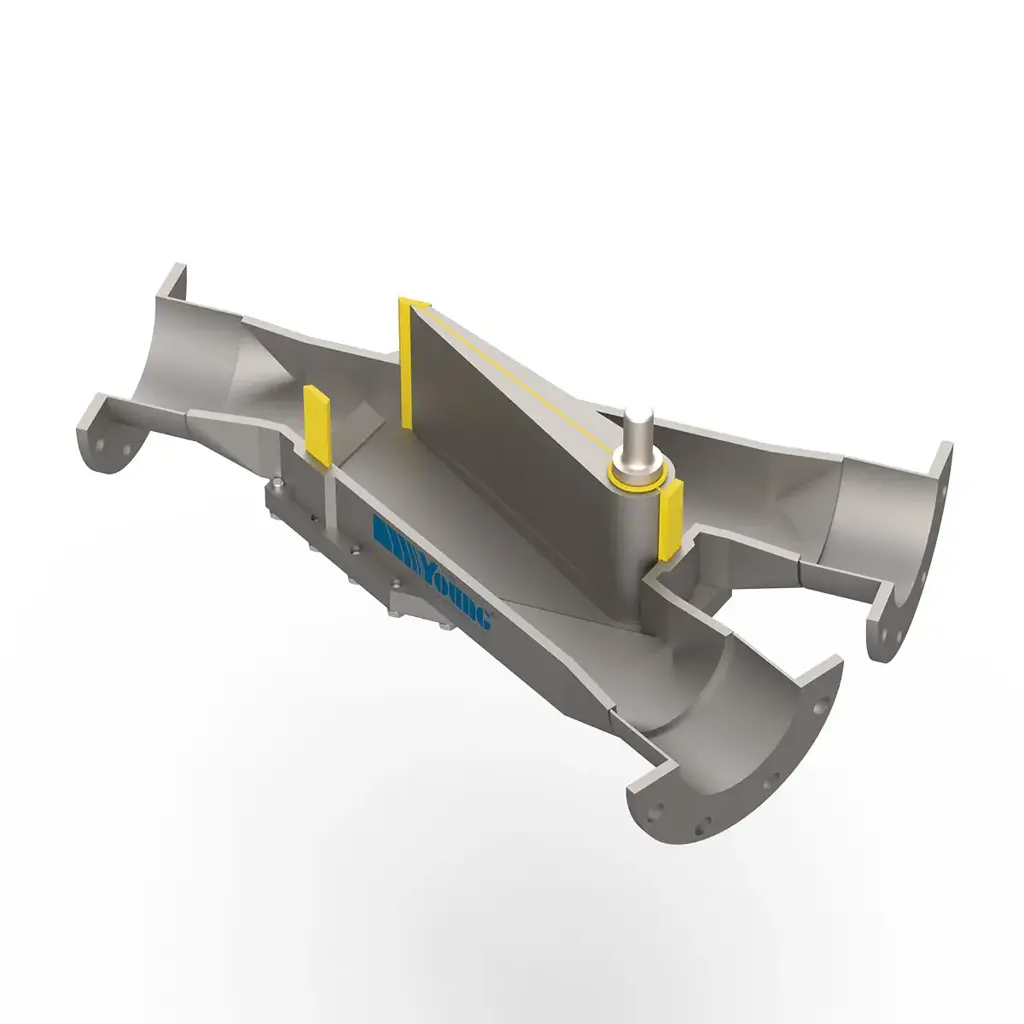

The Asymmetrical Swing Gate is your solution for efficient material routing in pneumatic conveying systems, guaranteeing proper gate alignment and even torque distribution. The two-way diverter valves are used for routing bulk material flow from one line to either of two lines or from two lines to one line or connected in series to for diverting to multiple lines. Its precision-machined sealing surfaces and heavy-duty cast construction ensure minimal leakage and long service life, reducing downtime and maintenance costs.

Features & Options

With a unique offset design and robust ball bearing support, the Model B features Teflon sealing strips and "O" rings for an airtight seal. The valves are designed with one diversion leg offset 30° from the straight through leg. The standard size range is 2″ through 12″ with larger sizes available upon request. Removable side plates provide quick access to the valve interior without disconnecting it from your system, minimizing downtime and production losses.

- For use in positive or negative pneumatic conveyors

- Mounts in any position without loss of efficiency

- Plain ends for compression coupling

- Disassemble without removing from the convey line

- 15 PSIG Housing and differential pressure or vacuum

- Made of cast steel and cast stainless steel

- Raw materials are traceable to standard specifications with ASTM

- Up to 250°F operation temperature

- Teflon sealing strips on both sides of swing gate

- White neoprene sealing strips at the hub and tips areas of the gate

- Grounding and bonding connection to NFPA specifications

- Painted blue enamel epoxy

- Completely assembled and tested

- Flanged or plain end connections

- High pressure designs

- High temperature design

- Special sizes available

- Special materials available, including 316 stainless steel and Hastelloy

- Interior coating for abrasive resistance includes chrome plating, nickel plating, tungsten carbide, Stellite, Teflon

- Interior polishes and cleanup

- Special sealing materials as graphite, food grade PTFE

- Rotary pneumatic operator, with NEMA 4 single solenoid valves, single-pole double-throw and 2 limit switches – one indicating for each leg

- Electric operator, with 2 limit switches – one switch for each leg

- Manual operator

- Painted or coated per customers specification

Specifications

| Size | OAH | Material of Construction | Actuator Options | Standard Design Temp. | Standard Design Pressure |

|---|---|---|---|---|---|

| 2 | 21 | Carbon Steel* Stainless Steel* Aluminum* Hastelloy^ Titanium^ |

Pneumatic Electric Manual | 250°F | 15 PSIG |

| 3 | 25.75 | ||||

| 4 | 28.62 | ||||

| 5 | 31.25 | ||||

| 6 | 34.25 | ||||

| 8 | 39.5 | ||||

| 10 | 48 | ||||

| 12 | 52 |

*Cast or Fabricated

^Fabricated Only

Customization

Whether you require high-pressure capabilities, specific materials of construction, or specialized coatings, we can configure your valve to meet your exact requirements. Choose from a variety of drive options, including rotary pneumatic, electric, or manual, to match your operational needs.