Bulk Bag Handling

Young Industries' bulk bag unloading systems are designed to offer efficient and dust-free material handling solutions for bulk bag discharging. These systems accommodate various bag sizes and are equipped with features like hoist systems, bag conditioners, and dust collection options to ensure smooth operation. The systems can handle a wide range of materials, from free-flowing to difficult-to-discharge products, offering flexibility in a variety of industrial applications.

These systems incorporate options such as pneumatic bag massagers, vibratory units, and manual or automatic bag cutting systems. They are engineered for safety, ensuring reliable discharge while protecting operators from dust and material spills.

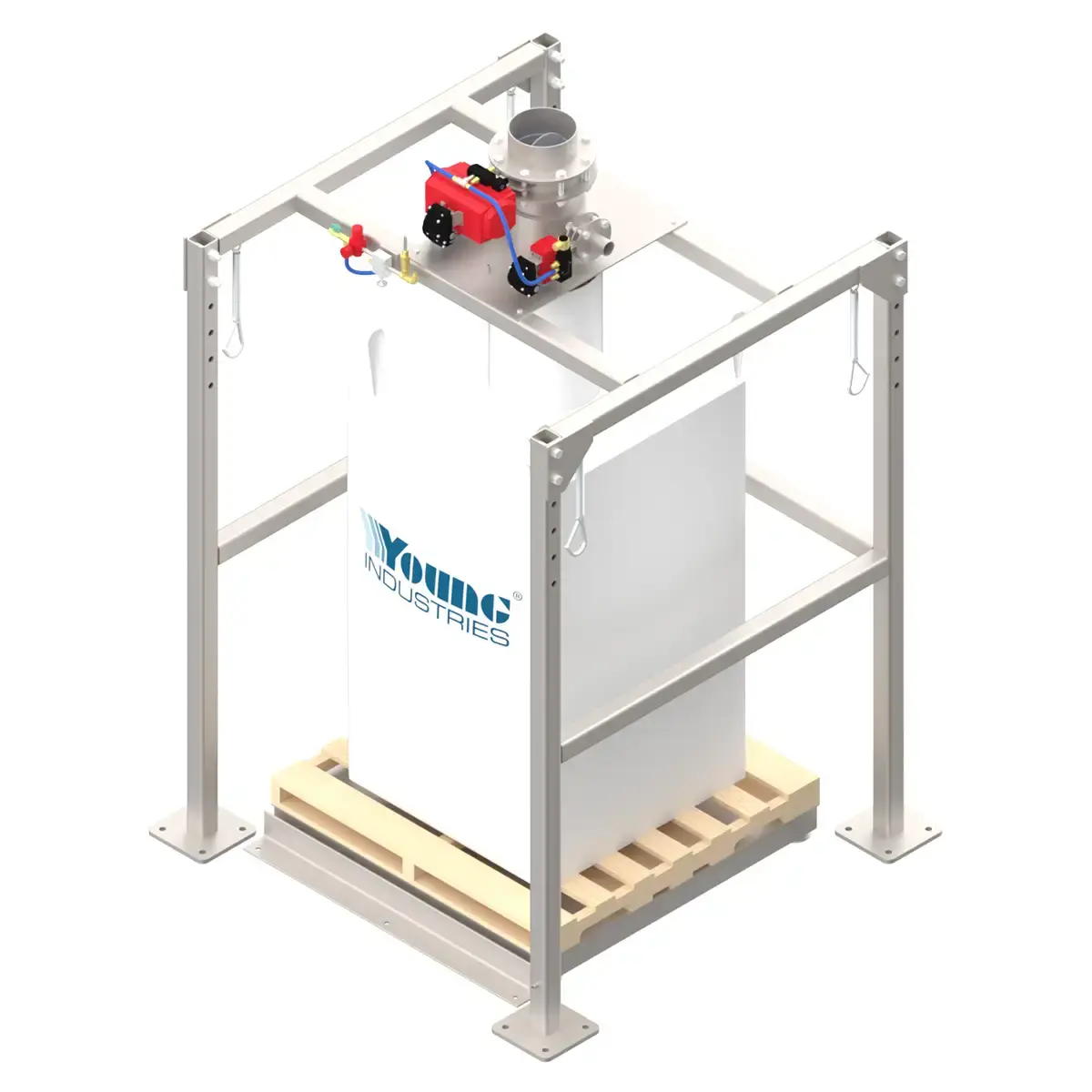

Young Industries offers durable Bulk Bag Unloading Frames with a variety of safety features. View our product features and options here.

Learn More

Young Industries Low Headroom Direct From Bag “DFB” Unloader is specifically designed for those applications with minimal headroom.

Learn More

Young Industries "Multi-Fill" Bulk Bag Filling Station is designed and manufactured for fill bulk bags with finished product.

Learn More