Mixers

Efficient Mixing Solutions

Young Industries specializes in high-performance mixing solutions designed to meet the most demanding processing needs. Our Horizontal Ribbon Mixers deliver precise and uniform batch mixing, ideal for blending powders, granules, and other bulk materials with superior efficiency. For continuous processing, our Twin-Shaft Continuous Mixers ensure consistent and thorough mixing, perfect for applications requiring uniform product flow. Built with precision, for durability and ease of maintenance, these mixers are engineered to enhance productivity and deliver reliable results in a wide range of industries.

Achieve fast, homogenous blending with Young Industries Horizontal Ribbon Mixers.

Learn More

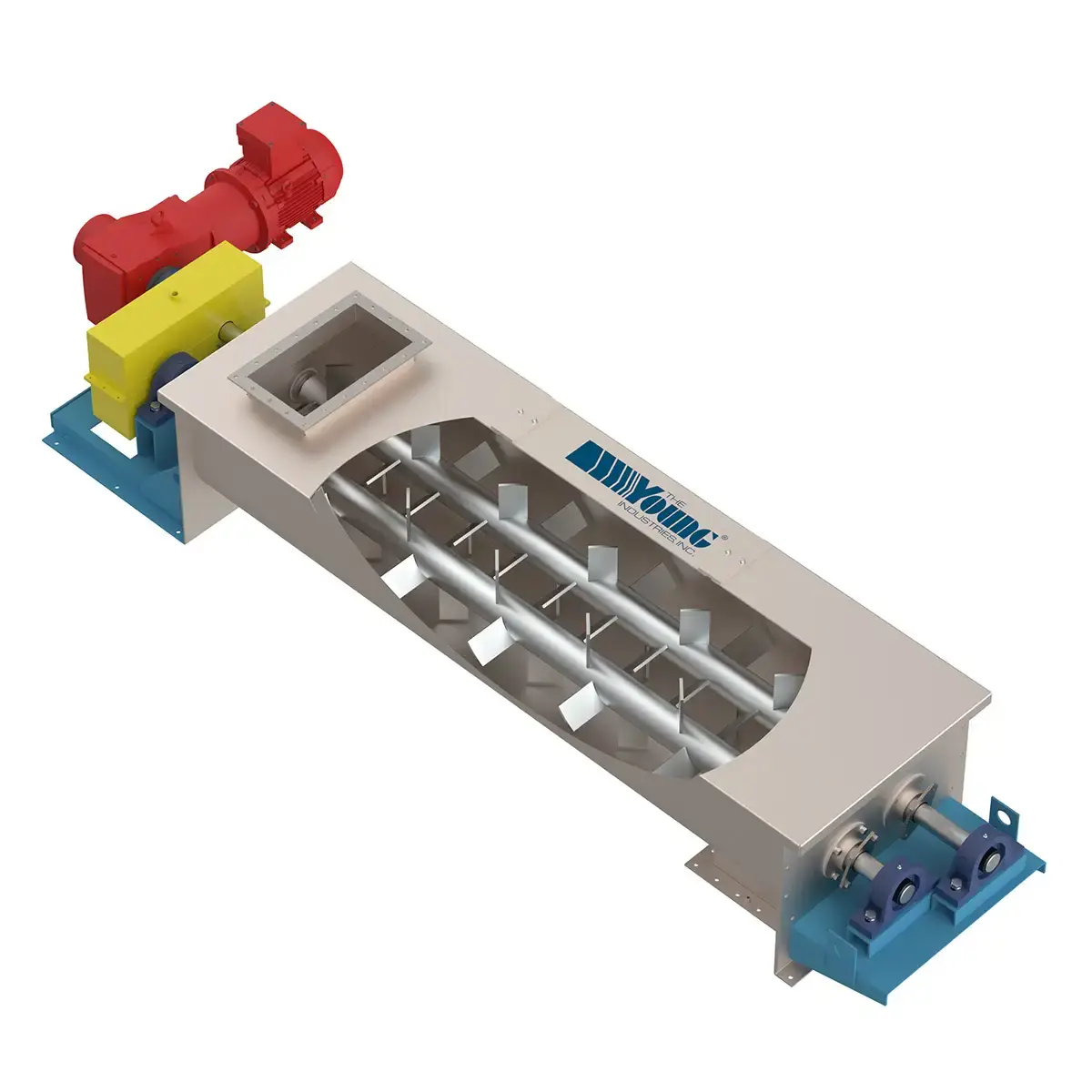

Achieve continuous blending with Young Industries Twin-Shaft Continuous Mixers.

Learn More