TransFlow Products

TransFlow® Products enhance process production by ensuring reliable material flow, even with challenging substances like pigments and sticky materials. This system allows for higher flow rates from existing hoppers and silos while significantly reducing maintenance costs due to its durable, corrosion-resistant media and lack of moving parts.

Additionally, TransFlow® minimizes downtime with easy cleaning and operates with less compressed air or gas than other aeration devices, ultimately lowering your overall operational costs.

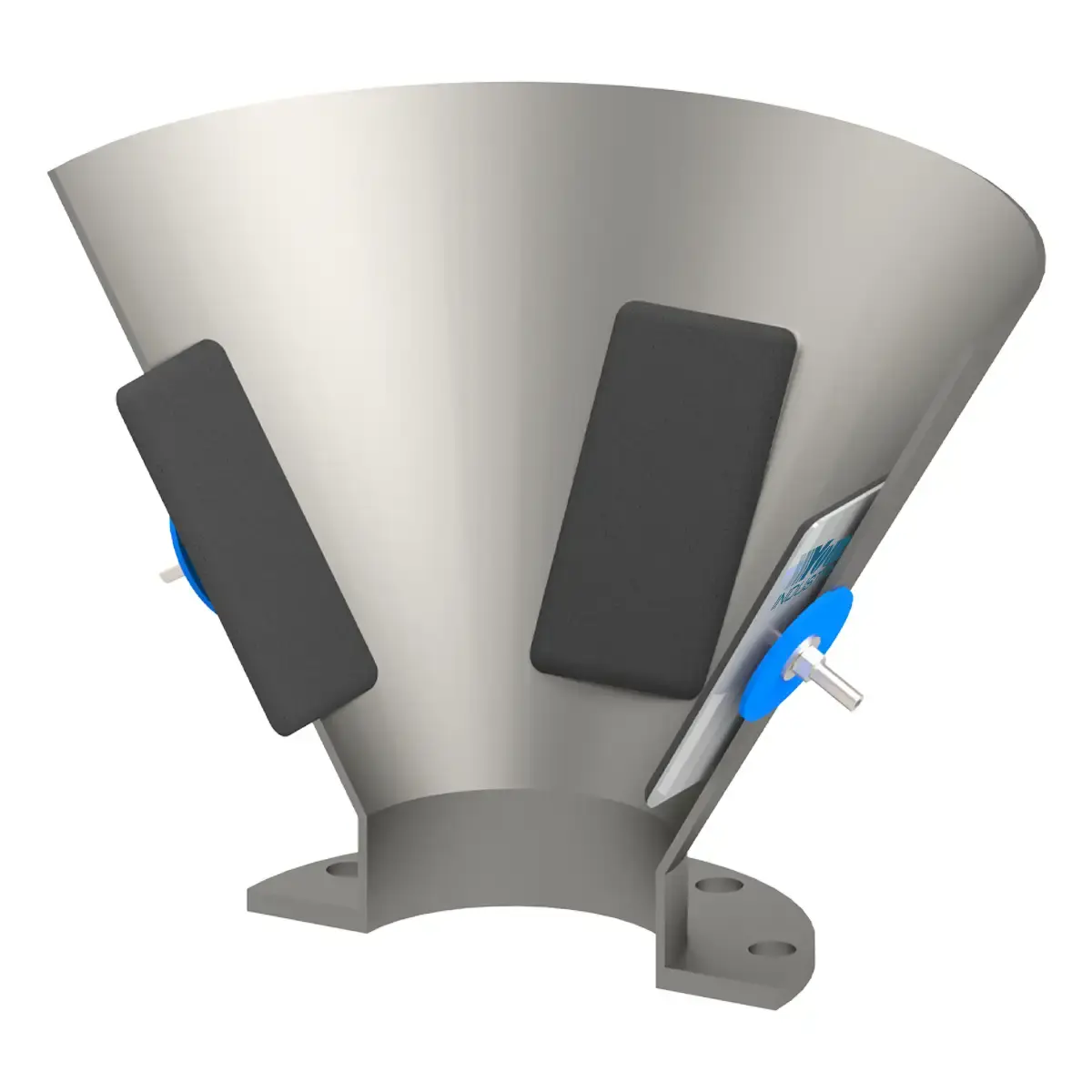

Eliminate flow problems and boost productivity with Young Industries' Silentflow Bin Dischargers featuring TransFlow® technology.

Learn More

Enhance powder flow and prevent clogs with the Young Industries PowderFlow Butterfly Valve.

Learn More

TransFlow Pads outperform other fluidization methods with their superior design. See why TransFlow Pads are preferred over other fluidization options!

Learn More

Protect personnel and enhance material flow with Young Industries' SafetyFlow® Grating.

Learn More