Weighing & Batching

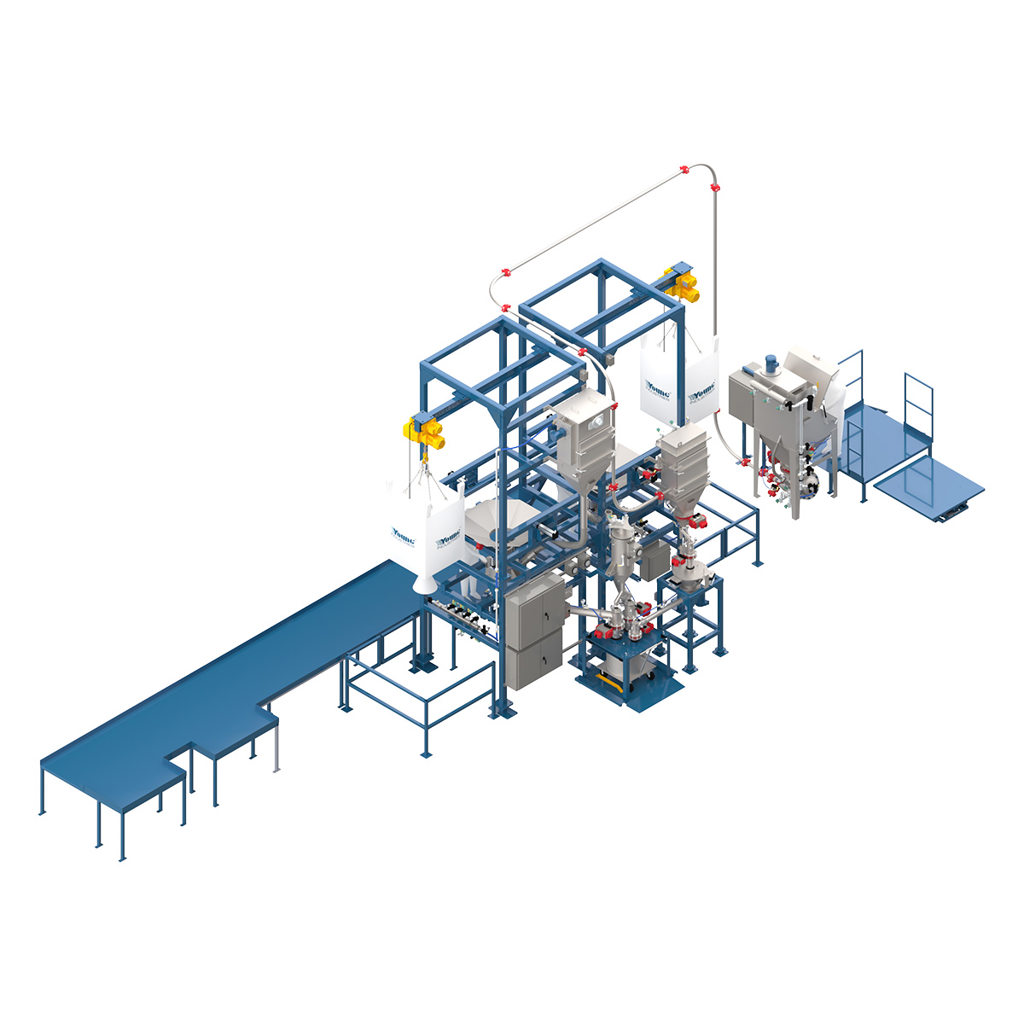

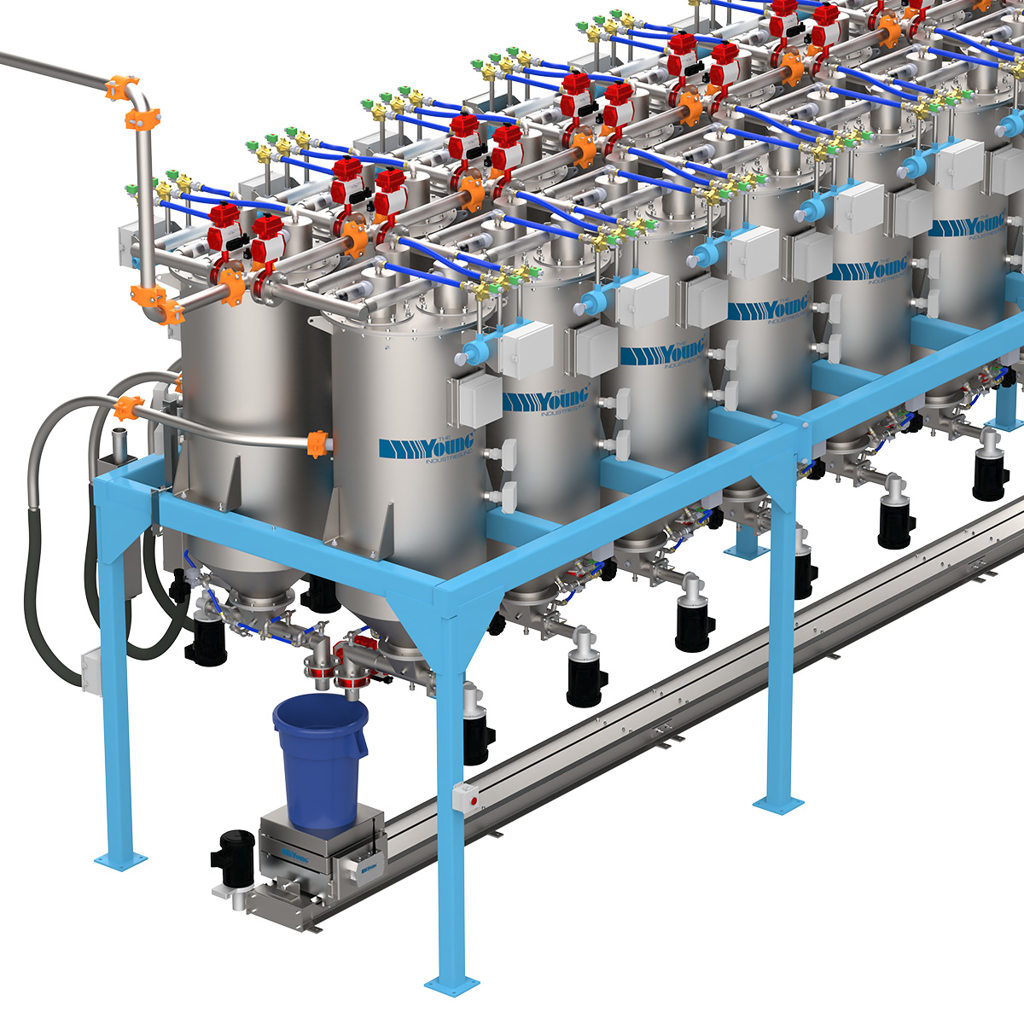

Young Industries delivers custom Weighing and Batching Systems tailored to meet the most demanding requirements for accuracy, process flow, and material characteristics. Whether you're managing a single product or multiple components, our Gain-in-Weight and Loss-in-Weight systems deliver reliable, efficient, and precise batch processing. With decades of expertise handling challenging materials, we provide solutions that integrate seamlessly into your operation.

Features & Options

Young Industries Weighing and Batching Systems are built with precision and efficiency in mind.

Every system is engineered to meet your unique process requirements, offering advanced features and flexible options to handle a wide range of materials and applications.

From durable construction to innovative control systems, our weighing and batching solutions deliver consistent, repeatable performance.

- Gain-in-Weight and Loss-in-Weight systems for single or multi-product batching

- Systems capable of handling fine, cohesive materials with optional fluidizing media

- Durable materials including carbon steel, 304/316 stainless steel, and special coatings

- Systems designed for standard operating temperatures up to 250°F User-friendly touch-screen interface with built-in help menus

- Ethernet IP communication for seamless integration with other control systems

- Multi-level password protection for secure access

- Bench and platform scales for small-batch ingredient weighing

- Bulk Bag Unloading Stations and Bag Dump Stations

- Day Bins, collection hoppers, and check weigh bins

- Transvair Aero-Mechanical Conveyors and pneumatic conveying systems

- Additional equipment controls integrated into the control panel

- Special coatings and finishes for harsh environments

- Systems designed for alternative electrical voltages (e.g., 575 VAC, 120 VAC)

- Equipment and controls rated for NEMA 4X or hazardous locations

Specifications

Standard Features

| Materials of Construction | Carbon Steel, 304/304L Stainless Steel, 316/316L Stainless Steel |

|---|---|

| Operating Temperature | 250 °F |

| System Controls | Loss-in-weight, Gain in weight |

| Screw Feeder Rate | .08-1,450 cu. ft./hr. |

| Screw Size | 1"-8" |

| Holding Hopper Capacity | 1.0 cu. ft. - 40 cu. ft. |

| Controls Operation | Local, Remote |

| Instrumentation Rating | NEMA 4 |

| Electrical Voltage Rating | 3 ph., 60 Hz., 230/460 VAC, 24 VDC |

Optional Features

| Product Handling | Transflow Fluidizing Media |

|---|---|

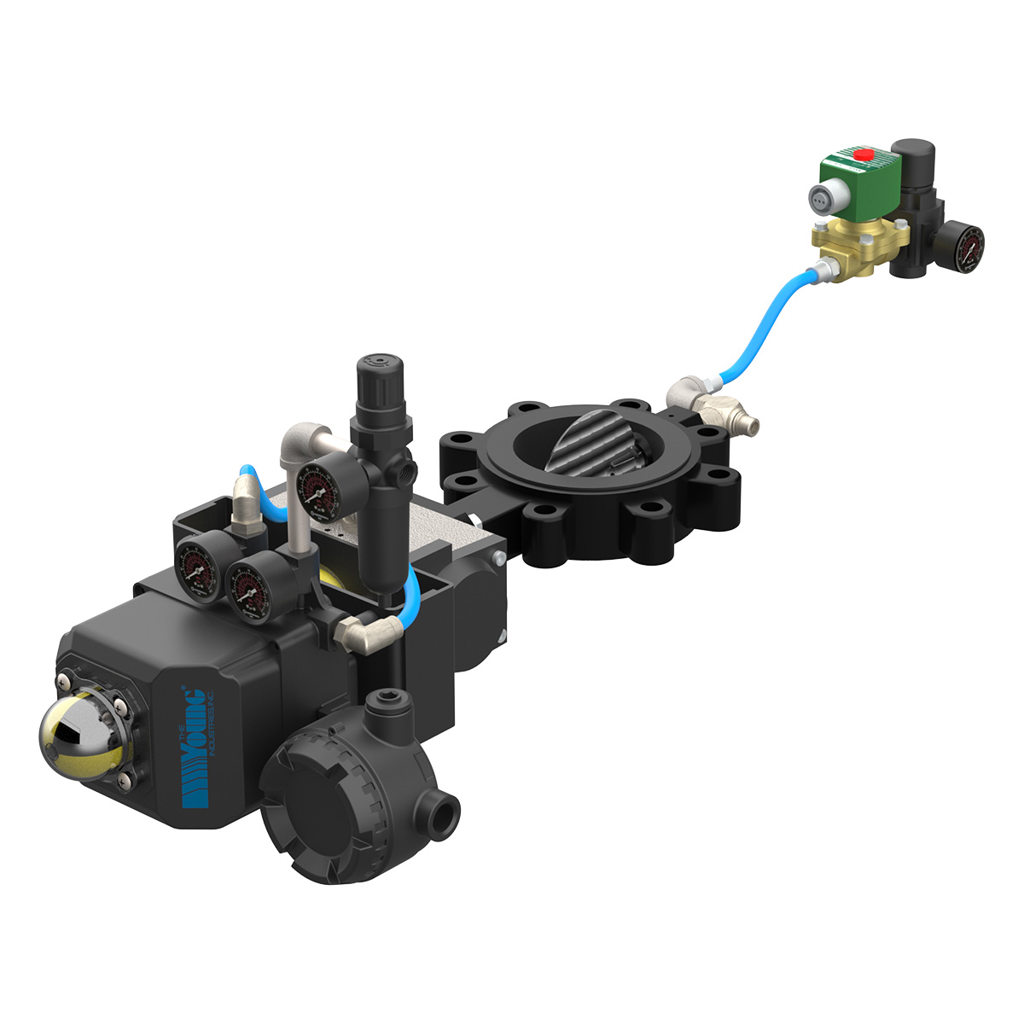

| Product Conditioning and Release | PowderFlow Butterfly Valves, HDPE Auger Flighting and Center Shaft |

| Drive Modulation | Motor Starters, Variable Frequency Drives |

| System Filling | Bulk Bag Unloading Station, Transvair Aero-mechanical Conveyors, Pneumatic Conveying, Holding Bins, Filters, Filter Receivers, Separators |

| Downstream Receiving | Collection Hopper, Transvair Aero-mechanical Conveyors, Pneumatic Conveying, Check Weigh Bins, Filters, Filter Receivers, Separators |

| Compounding Systems | Horizontal Ribbon Mixer sized .25 cu. ft. - 1500 cu. ft. |

| Instrumentation Rating | NEMA 4x, 7/9 |

| Electrical Voltage Rating | 3 ph., 60 Hz., 575 VAC, 1 ph., 60 Hz., 120 VAC |

Customization

At Young Industries, we know that every material handling process is unique. That’s why we specialize in custom-designed weighing and batching systems that meet your specific requirements for accuracy, efficiency, and material compatibility.